Nov . 25, 2024 14:21 Back to list

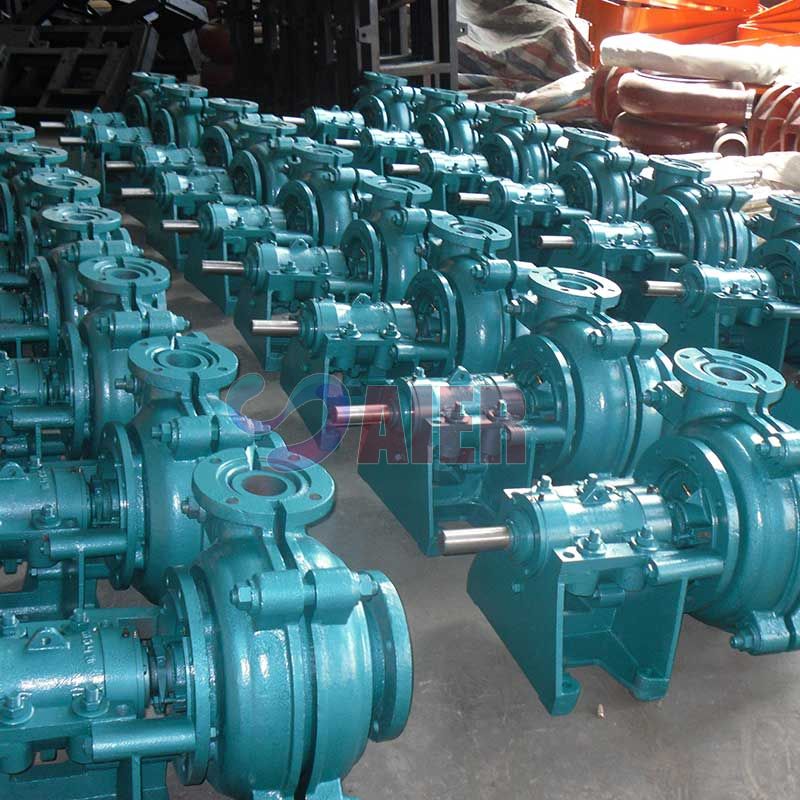

Efficient AH Slurry Pump Solutions for Heavy-Duty Industries and Applications

Understanding AH Slurry Pumps A Comprehensive Guide

Slurry pumps are essential equipment used in various industries for transporting abrasive liquids and solid mixtures. Among these, the AH slurry pump stands out for its reliability and efficiency in handling challenging materials. This article will provide an overview of the AH slurry pump, its design features, applications, advantages, and maintenance considerations.

What is an AH Slurry Pump?

The AH slurry pump is a type of centrifugal pump designed specifically for pumping slurries, which are mixtures of water and solid particles. This pump is part of the wider category of slurry pumps known for their robust construction and superior performance in demanding conditions. The “AH” designation signifies a specific design series manufactured by several reputable brands globally, known for their durability and versatility.

Design Features

The AH slurry pump possesses several key design features that enhance its performance

1. Heavy-Duty Construction The pump is typically made from high-chrome alloy or rubber lining materials, allowing it to resist wear and corrosion. This makes the AH slurry pump particularly suitable for abrasive slurries commonly found in mining, mineral processing, and dredging.

2. Adjustable Impeller The impeller can be adjusted to optimize the pump’s performance based on the specific density and viscosity of the slurry being pumped. This feature is crucial for maintaining efficiency and longevity.

3. Wide Range of Sizes AH slurry pumps come in various sizes to cater to different pumping capacities and applications, from small operations to large-scale industrial needs.

4. Simple Design The pump’s design allows for easy maintenance and repair, which is vital in minimizing downtime in industrial settings.

Applications

AH slurry pumps are widely used across many industries

- Mining and Mineral Processing These pumps are essential for transporting ore slurries and tailings, allowing for the efficient movement of heavy materials within a mining operation.

- Construction In construction sites, AH slurry pumps handle cement slurries and water mixtures, making them indispensable for concrete pumping and ground remediation projects.

- Wastewater Treatment The pumps are also effective in transporting various types of sludge and wastewater mixtures, playing a pivotal role in municipal and industrial wastewater facilities.

ah slurry pump

- Dredging Operations AH slurry pumps are used in dredging operations to remove sediment from water bodies, contributing to maintaining navigable waterways.

Advantages

The AH slurry pump offers numerous advantages that make it a preferred choice in various applications

- High Efficiency Designed for optimal flow characteristics, these pumps can handle thick and viscous slurries with minimal energy consumption.

- Durability With their robust construction, AH slurry pumps can withstand harsh working environments, contributing to extended service life.

- Versatility The ability to adjust the impeller and choose from various configurations allows operators to tailor the pump to specific slurry types and operating conditions.

- Ease of Maintenance With simple design elements and interchangeable parts, maintenance is straightforward, reducing operational downtime.

Maintenance Considerations

Ensuring the reliable operation of AH slurry pumps requires regular maintenance. Here are a few key practices

1. Routine Inspections Frequent checks for wear and tear, especially on the impeller and casing, help in early identification of potential issues.

2. Proper Lubrication Ensuring that all moving parts are adequately lubricated will prevent overheating and premature failure.

3. Monitoring Performance Keeping a close eye on the pump’s performance metrics can assist in detecting any deviations that could indicate problems.

4. Scheduled Overhauls Regular scheduled maintenance can keep the pump working efficiently and extend its lifespan.

Conclusion

The AH slurry pump is a vital piece of equipment in handling slurries across various industries. With its robust design, versatility, and efficiency, it is well-suited for a wide range of applications. By understanding its features and ensuring proper maintenance, operators can maximize performance and extend the lifespan of these essential pumps. Whether in mining operations, wastewater treatment, or construction, the AH slurry pump remains a cornerstone of industrial fluid transportation.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025