Th10 . 01, 2024 03:38 Back to list

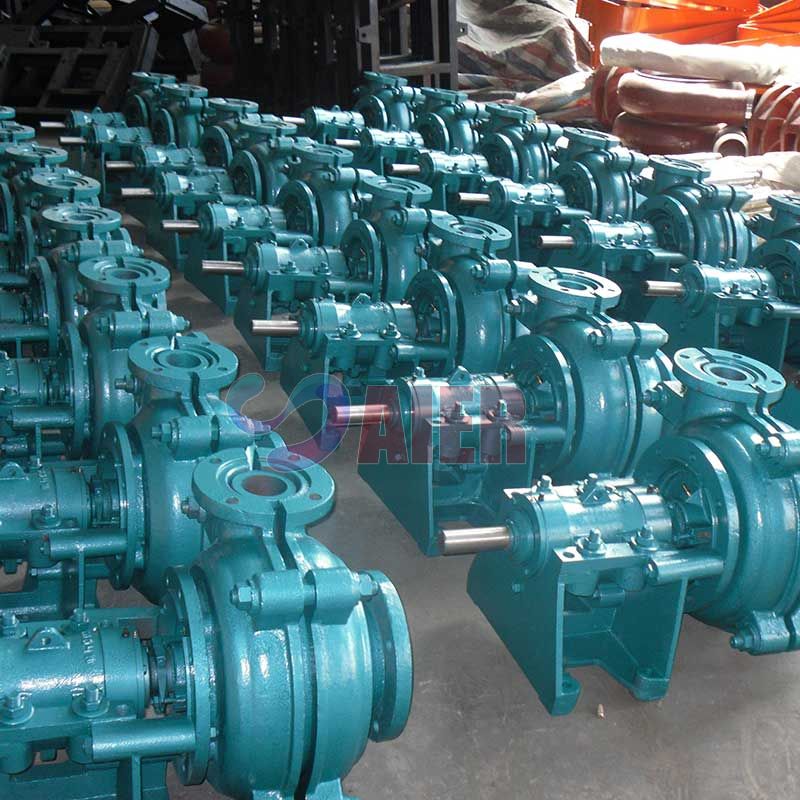

High Efficiency Abrasive Wastewater Centrifugal Pump Manufacturer for Industrial Applications

The Role of High-Quality Abrasive Pumps in Wastewater Management

In today's industrial landscape, effective wastewater management is a critical aspect of environmental sustainability. Central to this process is the use of high-quality abrasive pumps, particularly centrifugal pumps, which are designed to handle challenging fluid types that contain solid particles and abrasive materials. This article explores the importance of high-quality abrasive pumps, focusing on their design, applications, and the benefits they bring to wastewater treatment facilities.

Understanding Centrifugal Pumps

Centrifugal pumps are among the most commonly used pumps in various industries, especially in wastewater management. These pumps operate on a straightforward principle they convert rotational energy, typically from an electric motor, into hydrokinetic energy of the fluid. As the impeller spins, it creates a centrifugal force that propels the liquid outward, aiding in the movement of wastewater through treatment facilities.

However, not all centrifugal pumps are designed to handle abrasive materials. High-quality abrasive pumps are specifically engineered to withstand the wear and tear associated with particles present in wastewater, such as sand, silt, and other solid debris. This durability is essential to ensure longevity and reliability in wastewater systems, where pump failures can lead to costly downtimes and environmental hazards.

Key Features of High-Quality Abrasive Pumps

One of the hallmarks of high-quality abrasive pumps is the materials used in their construction. They are often made from abrasion-resistant materials such as high-chrome iron or specialized alloys that resist corrosion and wear. Furthermore, the design of these pumps usually incorporates features such as

1. Wear Plates and Liners These components absorb the impact of abrasive particles, extending the service life of the pump. 2. Self-Priming Capability This feature is essential for handling wastewater with variable flow levels, ensuring that the pump can effectively draw in fluid without manual intervention. 3. Variable Speed Drives These allow for the adjustment of pump speeds depending on the flow rate requirements, enhancing efficiency and energy savings.

Applications in Wastewater Management

high quality abrasives pump wastewater centrifugal pump factory

High-quality abrasive pumps are used in diverse applications within wastewater treatment facilities. They play a vital role in

- Sludge Transfer Moving slurry-like materials from one stage of treatment to another is crucial. Abrasive pumps efficiently handle the thick and particle-laden fluids typical of sludge. - Effluent Treatment These pumps are employed to transport treated wastewater to disposal sites or water reclamation facilities, ensuring that the water is moved safely and efficiently. - Industrial Applications Many industries, including mining, construction, and food processing, contribute to wastewater complexities. High-quality abrasive pumps are essential for managing this wastewater effectively.

Benefits of Using High-Quality Abrasive Pumps

Investing in high-quality abrasive pumps offers numerous benefits

1. Increased Reliability Robust construction and specialized design reduce the likelihood of failures, thereby minimizing maintenance costs and downtime. 2. Cost-Efficiency Although the initial investment may be higher, the longevity and reduced maintenance of high-quality pumps lead to significant savings over time. 3. Enhanced Performance These pumps perform efficiently under challenging conditions, ensuring smooth operation and consistent flow rates. 4. Environmental Impact By preventing leaks and ensuring that wastewater is properly treated, abrasive pumps contribute considerably to environmental protection efforts.

Conclusion

In the complex world of wastewater management, the role of high-quality abrasive pumps cannot be overstated. Their unique design and durable construction make them ideal for handling the specific challenges posed by wasted materials in treatment processes. As industries continue to focus on sustainable practices and effective wastewater management solutions, investing in reliable centrifugal pumps will play an essential role in ensuring cleaner, safer environments for future generations.

By choosing the right factory for high-quality abrasive pumps, companies can facilitate their wastewater treatment processes, enhancing operational efficiency and contributing to global environmental goals.

-

China Portable Slurry Pump Manufacturer - Durable & Efficient Submersible Design

NewsMay.29,2025

-

High-Quality Submersible Slurry Pumps Reliable Manufacturer & Supplier

NewsMay.29,2025

-

High-Quality Sand Dredge Pump 8 Durable Manufacturer & Supplier

NewsMay.29,2025

-

Electric Submersible Slurry Pump - Durable & Efficient China Suppliers

NewsMay.29,2025

-

Submersible Slurry Pump with Agitator Durable China Suppliers & Manufacturers

NewsMay.29,2025

-

Vertical Sump Pump Rubber Lined - Durable Corrosion-Resistant Design China Manufacturers

NewsMay.29,2025