Сер . 14, 2024 12:44 Back to list

Choosing the Right Industrial Slurry Pump for Efficient Fluid Handling in Various Applications

Understanding Industrial Slurry Pumps An Essential Component in Various Industries

Industrial slurry pumps play a pivotal role in the transportation of abrasive, viscous, and heavy slurries in numerous industrial applications. These specialized pumps are designed to handle mixtures of solids and liquids, which are often found in mining, mineral processing, construction, and wastewater management sectors. This article explores the functionality, types, and applications of industrial slurry pumps, highlighting their significance in improving operational efficiency.

What is a Slurry Pump?

A slurry pump is a type of pump specifically engineered to move slurries—mixtures of solids and liquids. Unlike standard pumps that handle clean water, slurry pumps are built to endure harsh environments and abrasive materials. They typically feature robust materials, such as high-chrome iron, rubber, or ceramic, to resist wear caused by the solid particles within the slurry. Their design also includes features that minimize turbulence, enhancing the pump’s efficiency and prolonging its service life.

Types of Slurry Pumps

There are several types of slurry pumps, each tailored to specific operational needs

1. Centrifugal Slurry Pumps The most common type, centrifugal slurry pumps use rotational energy to move slurries. They are characterized by their simple design and ability to handle varying flow rates and pressures.

2. Positive Displacement Pumps These pumps operate by trapping a fixed amount of slurry and forcing it into the discharge pipe. They are particularly useful for high-viscosity slurries where centrifugal pumps may struggle.

3. Vertical Slurry Pumps Designed for submerged applications, vertical slurry pumps are often used in sumps or pits. Their vertical orientation requires less floor space and allows for easy installation in confined areas.

Applications of Slurry Pumps

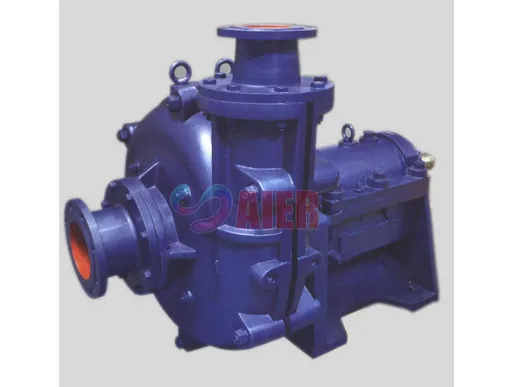

industrial slurry pump

Industrial slurry pumps are crucial in various sectors

- Mining and Mineral Processing In mining operations, slurry pumps transport a mixture of ore, water, and chemicals from one stage of processing to another. Their ability to handle heavy and abrasive materials makes them indispensable in this industry.

- Construction Slurry pumps are often used to manage excavated material and wastewater. They facilitate the removal of concrete slurry and other mixtures resulting from construction activities.

- Wastewater Treatment In wastewater treatment plants, these pumps help in handling mixed waste materials. They efficiently convey sludge and other solid waste to treatment facilities.

- Chemical Processing These pumps are also critical in the chemical industry for transporting corrosive slurries, ensuring safe and efficient processing of materials.

Benefits of Using Slurry Pumps

The use of industrial slurry pumps offers numerous advantages. They enhance operational efficiency by reducing downtime associated with maintenance and wear, thereby lowering overall costs. Furthermore, their robust construction enables them to handle challenging environments, ensuring reliability and longevity.

In addition to durability and efficiency, slurry pumps contribute to environmental sustainability by facilitating the recycling and proper disposal of waste materials. By efficiently transporting slurries, industries can minimize their ecological footprint and comply with environmental regulations.

Conclusion

Industrial slurry pumps are an integral component of various industrial processes, proving essential in sectors that require the movement of slurries. Understanding the types, applications, and benefits of these pumps allows industries to optimize their operations, ensuring effective handling of abrasive materials while maintaining cost-effectiveness and sustainability. As technology advances, slurry pumps continue to evolve, promising enhanced performance and reliability for the future.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025