فېۋرال . 06, 2025 02:35 Back to list

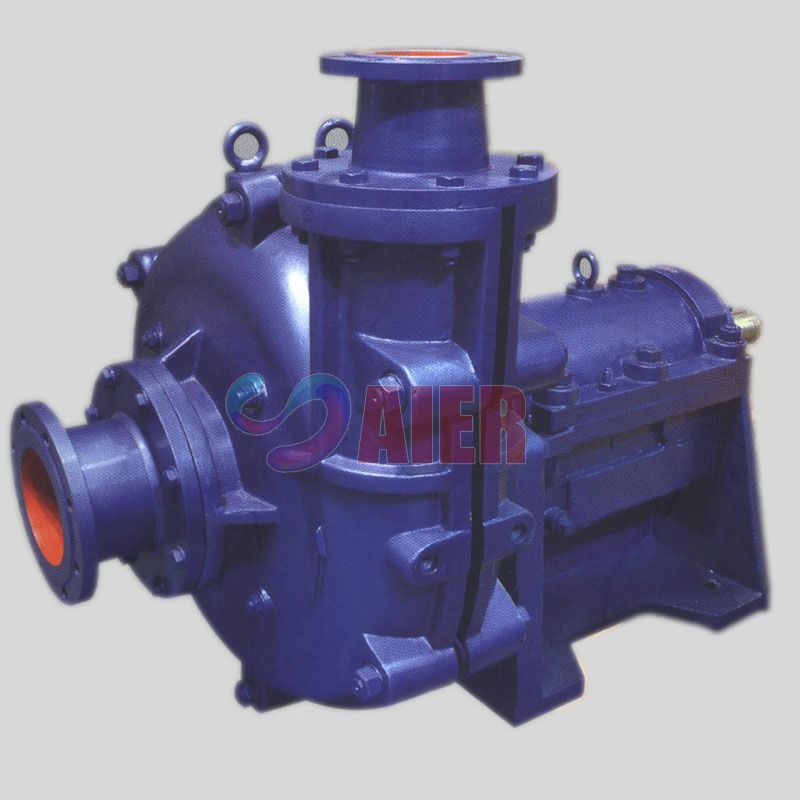

warman slurry pump bearing assembly

The Warman slurry pump bearing assembly is pivotal in ensuring the optimal performance and longevity of slurry pumping systems. These assemblies are not only crucial in maintaining the efficiency of pumps in handling abrasive and corrosive materials, but they also embody an amalgamation of engineering finesse and practical application.

Real-world experiences testify to the impact of utilizing superior bearing assemblies. A mining operation in South America, for instance, reported a 35% reduction in maintenance frequency after switching to Warman slurry pumps, primarily attributing this improvement to their robust bearing assemblies. Such tangible benefits underline the significant return on investment when selecting high-quality components. Installing and maintaining these assemblies are exercises in technical precision. The bearing housing must be perfectly aligned, and the lubricant levels and types should conform to the dispensing environment. During the assembly process, professionals employ laser alignment tools and digital monitoring systems to ensure maximum accuracy. Furthermore, end-user training conducted by experts carries substantial weight in enhancing the proficiency of operators handling these systems. Training modules cover the nuances of assembly installations, troubleshooting, and preventative maintenance strategies. Such programs empower operators to maximize the lifespan and performance of their pump installations. In conclusion, the Warman slurry pump bearing assembly is a testament to innovation and reliability in fluid handling technology. Its design and manufacturing processes embody a deep-seated expertise in engineering, catering to the demanding needs of industries reliant on slurry pumps. The assembly not only supports the mechanical demands of pumping operations but also represents a commitment to durability and performance. By investing in high-quality components, businesses ensure sustainable operation and reduced long-term costs, ultimately enhancing their operational productivity.

Real-world experiences testify to the impact of utilizing superior bearing assemblies. A mining operation in South America, for instance, reported a 35% reduction in maintenance frequency after switching to Warman slurry pumps, primarily attributing this improvement to their robust bearing assemblies. Such tangible benefits underline the significant return on investment when selecting high-quality components. Installing and maintaining these assemblies are exercises in technical precision. The bearing housing must be perfectly aligned, and the lubricant levels and types should conform to the dispensing environment. During the assembly process, professionals employ laser alignment tools and digital monitoring systems to ensure maximum accuracy. Furthermore, end-user training conducted by experts carries substantial weight in enhancing the proficiency of operators handling these systems. Training modules cover the nuances of assembly installations, troubleshooting, and preventative maintenance strategies. Such programs empower operators to maximize the lifespan and performance of their pump installations. In conclusion, the Warman slurry pump bearing assembly is a testament to innovation and reliability in fluid handling technology. Its design and manufacturing processes embody a deep-seated expertise in engineering, catering to the demanding needs of industries reliant on slurry pumps. The assembly not only supports the mechanical demands of pumping operations but also represents a commitment to durability and performance. By investing in high-quality components, businesses ensure sustainable operation and reduced long-term costs, ultimately enhancing their operational productivity.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025