نويابىر . 22, 2024 10:44 Back to list

centrifugal pump for slurry factory

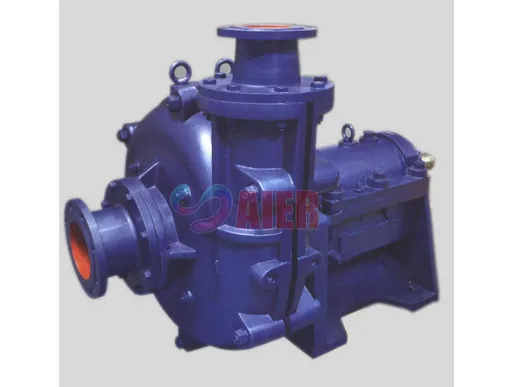

The Importance of Centrifugal Pumps for Slurry Applications in Factories

Centrifugal pumps play a crucial role in the efficient handling of slurry in various industrial applications. Slurry, a mixture of solid particles suspended in a liquid, presents unique challenges when it comes to transportation and processing. Factories requiring the movement of such mixtures depend on specialized equipment that can handle the abrasive and viscous nature of slurries. Among these, centrifugal pumps are a popular choice due to their effectiveness and reliability.

The Importance of Centrifugal Pumps for Slurry Applications in Factories

One of the primary advantages of using centrifugal pumps for slurry applications is their ability to handle large volumes. In factories, where the demand for efficiency and high throughput is critical, these pumps can significantly reduce processing times. Their ability to operate at various speeds and flows makes them suitable for different operational needs, ensuring that they can keep pace with production requirements.

centrifugal pump for slurry factory

Another significant benefit of centrifugal pumps is their durability and maintenance. Slurry can be abrasive to standard pump components, but many centrifugal pumps designed for slurry applications are constructed with wear-resistant materials that extend their service life. These pumps often feature easily replaceable parts, which reduces downtime during maintenance and keeps operations running smoothly. Regular maintenance of these pumps is essential, as it ensures optimal performance and prevents costly breakdowns.

Moreover, the design flexibility of centrifugal pumps allows for customization according to specific slurry characteristics. Factors such as particle size, concentration, and chemical nature can influence pump selection. By tailoring the pump design—such as impeller size, casing material, and wear-liner options—factories can optimize their operations for particular applications, further enhancing efficiency.

Energy efficiency is another important consideration in the selection of pumps for slurry transport. Centrifugal pumps are designed to minimize energy consumption while maximizing output. Many modern pumps incorporate advanced technologies, such as variable frequency drives (VFDs), which allow for precise control over pump speed and flow rate. This feature not only conserves energy but also contributes to lower operational costs, making it an appealing option for factories striving for sustainability.

In conclusion, centrifugal pumps are indispensable in the effective handling of slurry in factory settings. Their high efficiency, durability, and adaptability make them suitable for various applications, from mining and mineral processing to wastewater treatment and food production. By investing in quality centrifugal pumps, factories can ensure they manage their slurry handling requirements proficiently, contributing to overall productivity and operational success. As industries continue to evolve, the role of centrifugal pumps will undoubtedly remain pivotal in streamlining processes and enhancing manufacturing capabilities.

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025

-

High Quality Warman Slurry Pump Drawings Supplier & Factory Reliable Customization

NewsJul.06,2025

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025