Ноя . 28, 2024 02:31 Back to list

Vertical Slurry Sump Pump Manufacturing Solutions for Efficient Liquid Management

The Vertical Slurry Sump Pump A Comprehensive Overview of Its Factory Production

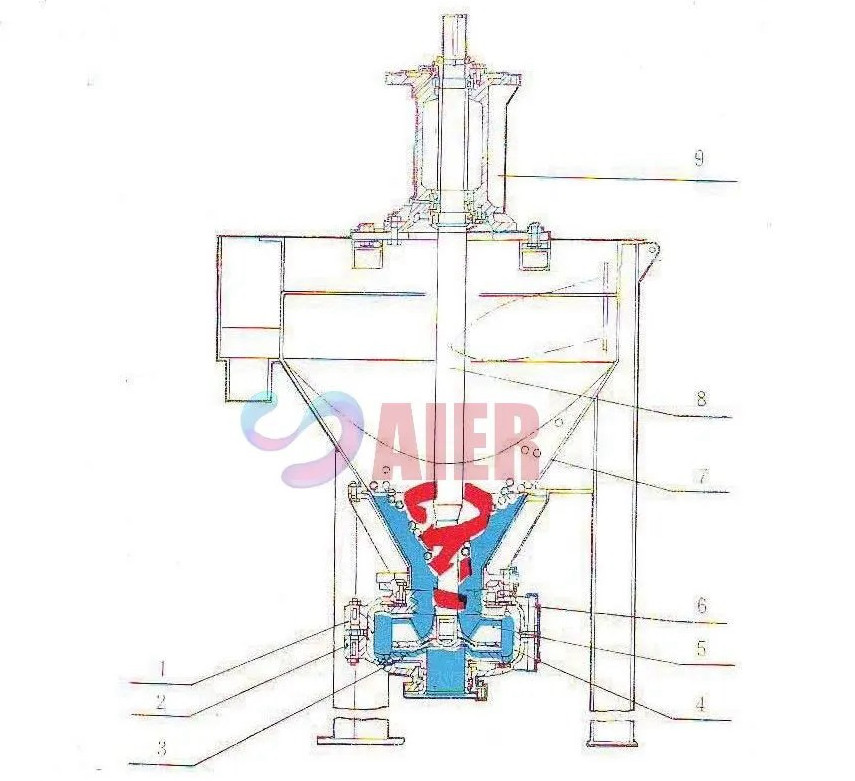

In the world of industrial pumping solutions, the vertical slurry sump pump stands out as a highly efficient and reliable choice for handling abrasive and corrosive materials. This article discusses the manufacturing process of these pumps in a dedicated factory setting, highlighting the technology, materials, and quality control measures involved in their production.

Understanding Vertical Slurry Sump Pumps

Vertical slurry sump pumps are specifically designed for applications that involve moving slurries—mixtures of liquid and solid particles—often found in mining, mineral processing, and wastewater treatment. Unlike standard pumps, these vertical models are submerged in a sump or pit, allowing them to handle high volumes of slurry without the exposure to wear and tear associated with horizontal pumps.

The Manufacturing Process

1. Design and Engineering

The manufacturing of vertical slurry sump pumps begins with a robust design and engineering process. Engineers use advanced CAD software to create detailed designs that optimize pump efficiency and durability. Factors such as flow rate, head requirements, and slurry characteristics are taken into account to ensure the final product meets customer specifications.

2. Material Selection

Choosing the right materials is crucial in the production of vertical slurry sump pumps. Due to their exposure to abrasive and corrosive substances, these pumps are usually made from high-strength alloys or rubber-lined components. The factory uses state-of-the-art materials like chrome alloy for the wet ends and heavy-duty steel for structural components. This ensures longevity and resilience against erosion.

3. Machining and Fabrication

Once the design and materials are confirmed, the machining process begins. CNC (Computer Numerical Control) machines are employed to ensure high precision in cutting, shaping, and assembling pump components. This automated process minimizes human error while maximizing efficiency and allows for the production of complex geometries that are essential for optimal pump performance.

vertical slurry sump pump factory

4. Assembly

After machining, the next step is assembly. Skilled technicians carefully put together all the pump components, including the impeller, casing, and motor. The assembly line is organized to systematically complete each step while maintaining quality standards. During this phase, technicians also install seals and bearings to ensure a watertight and reliable operation.

5. Quality Control

Quality assurance is a vital part of the production process. Factories implement rigorous testing procedures to ensure that each vertical slurry sump pump meets industry standards. Pumps undergo hydraulic tests to check for leaks and to ensure that they can handle the required flow rates. Additionally, components are inspected for dimensional accuracy and surface finish to prevent premature wear.

6. Painting and Finishing

Once assembly and quality checks are completed, the pumps go through a finishing process. This often involves applying protective coatings that resist corrosion and enhance durability. Aesthetics are also considered, as customers may prefer pumps that not only perform well but also look professional.

Market Applications and Trends

Vertical slurry sump pumps have a wide array of applications, particularly in sectors such as mining, dredging, and wastewater treatment. With the global emphasis on sustainability and efficiency, there is a growing trend towards designing pumps that reduce energy consumption while maximizing performance. Manufacturers are responding by developing innovative technologies such as variable frequency drives (VFDs) that allow for better flow control and energy savings.

Conclusion

The production of vertical slurry sump pumps in a factory setting involves a combination of advanced engineering, material science, precision machining, and rigorous quality control. As industries continue to demand efficient and reliable pumping solutions for challenging environments, the importance of modern manufacturing techniques and innovative designs will only grow. By investing in these technologies, manufacturers can ensure that their vertical slurry sump pumps not only meet but exceed market expectations, ensuring long-term success in a competitive landscape. The ongoing evolution within this field signifies a promising future for both producers and consumers alike, with enhancements that drive performance and sustainability forward.

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025