Фев . 13, 2025 03:33 Back to list

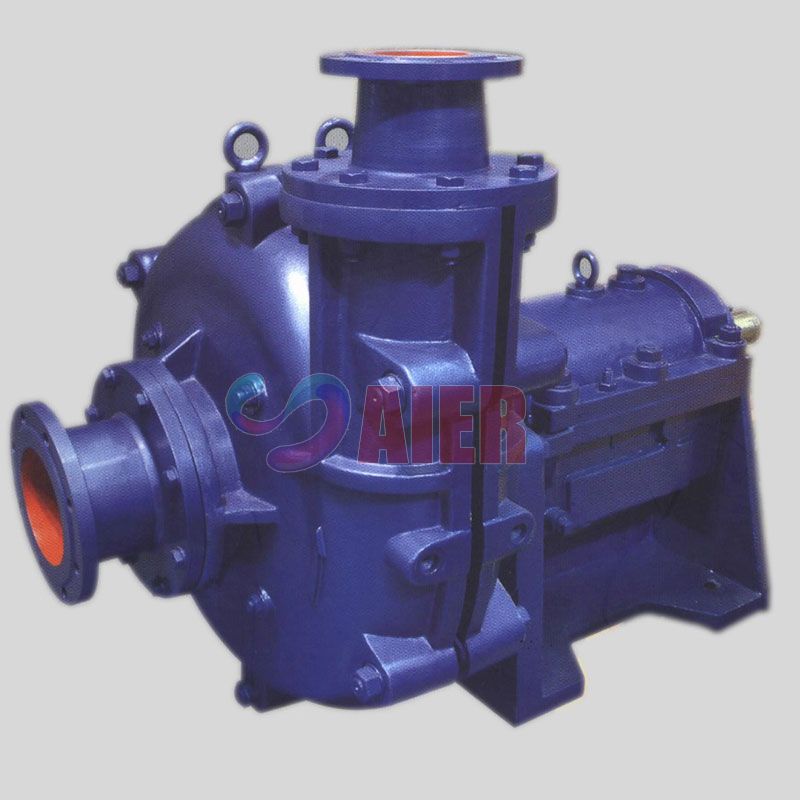

WZ High Efficiency Slurry Pump

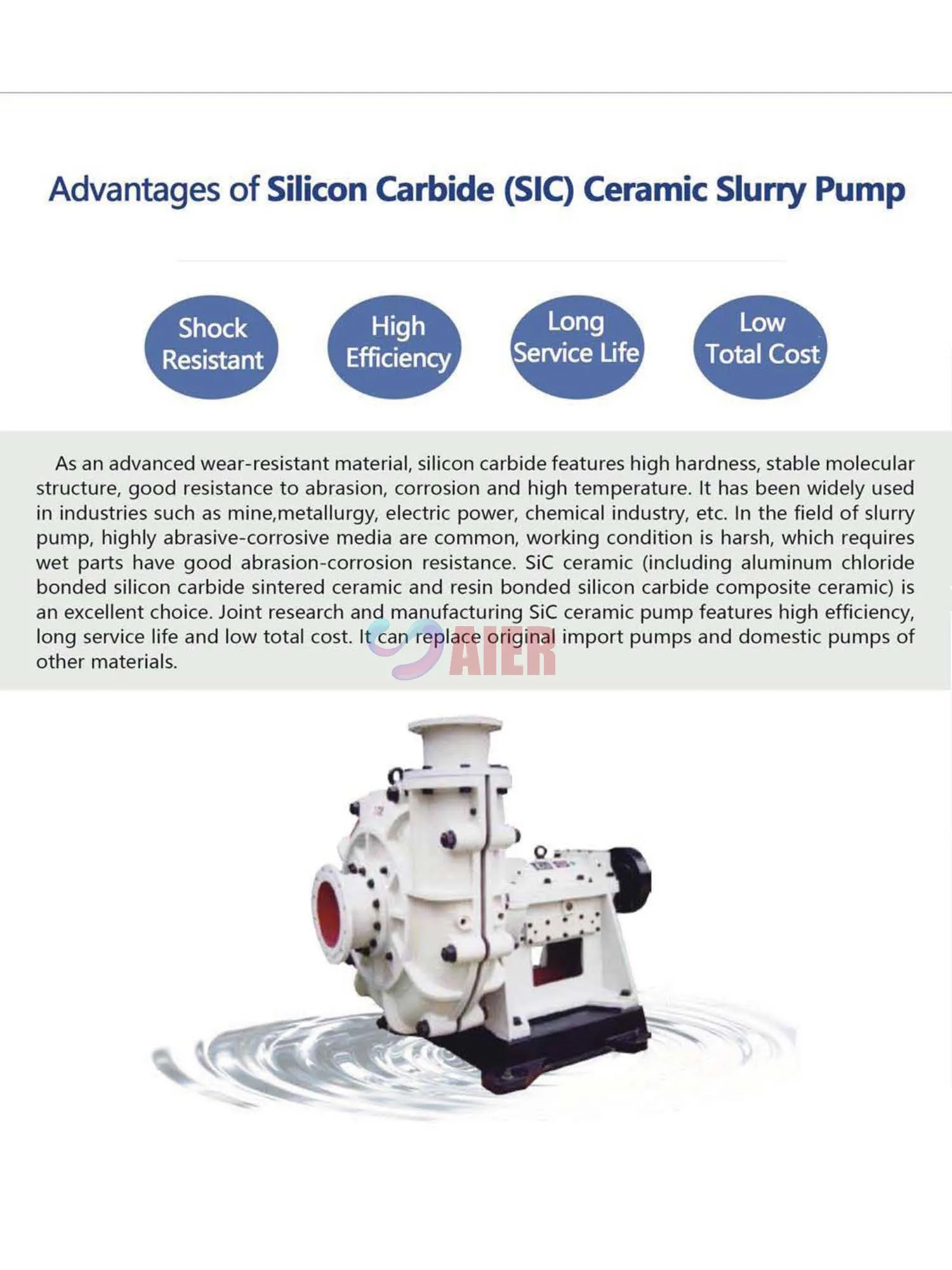

Twin casing slurry pumps are distinct for their robust design and remarkable efficiency in handling abrasive and corrosive slurries. Through years of field experiences and customer feedback, these pumps have become indispensable across industries such as mining, construction, and wastewater management. Their unique construction includes dual casings — where the outer casing holds the pressure, and the inner casing ensures the safe displacement of slurry materials — that increases safety, longevity, and operational efficiency.

Experience from field operators demonstrates the twin casing slurry pump's adaptability to varying environmental conditions. Whether dealing with highly acidic or alkaline slurries, or fluids laden with sharp particles, these pumps deliver unwavering performance. Their design inherently provides enhanced suction abilities and allows for a thicker slurry mixture, highlighting the pump's versatility across applications. Field technicians consistently report ease of installation and the intuitive nature of maintenance procedures, noting that operators can perform routine checks and services with minimal training. As twin casing slurry pumps become more integrated into modern industrial processes, their role in sustainable operations is increasingly recognized. By ensuring reliable slurry handling, these pumps allow for the recycling and treatment of materials otherwise deemed waste. This not only translates into economic benefits but also aligns with global sustainability goals aimed at minimizing environmental impact. Importantly, building trust within the twin casing slurry pumps market relies on transparent communication from manufacturers and suppliers. Providing in-depth product information, comprehensive technical support, and post-installation services ensures client satisfaction and fosters long-lasting professional relationships. Real-world testimonials and endorsements from clients who have benefitted from these pumps further contribute to their credibility. In conclusion, the twin casing slurry pump epitomizes a blend of innovative engineering, field-tested durability, and strategic design that meets contemporary industrial demands. Its dual casing technology significantly enhances its operational reliability and efficiency, proving to be an essential component in industries requiring robust slurry handling solutions. By integrating these pumps, businesses achieve a blend of performance, sustainability, and cost-effectiveness, reinforcing the pump's standing as an indispensable asset in advanced industrial applications.

Experience from field operators demonstrates the twin casing slurry pump's adaptability to varying environmental conditions. Whether dealing with highly acidic or alkaline slurries, or fluids laden with sharp particles, these pumps deliver unwavering performance. Their design inherently provides enhanced suction abilities and allows for a thicker slurry mixture, highlighting the pump's versatility across applications. Field technicians consistently report ease of installation and the intuitive nature of maintenance procedures, noting that operators can perform routine checks and services with minimal training. As twin casing slurry pumps become more integrated into modern industrial processes, their role in sustainable operations is increasingly recognized. By ensuring reliable slurry handling, these pumps allow for the recycling and treatment of materials otherwise deemed waste. This not only translates into economic benefits but also aligns with global sustainability goals aimed at minimizing environmental impact. Importantly, building trust within the twin casing slurry pumps market relies on transparent communication from manufacturers and suppliers. Providing in-depth product information, comprehensive technical support, and post-installation services ensures client satisfaction and fosters long-lasting professional relationships. Real-world testimonials and endorsements from clients who have benefitted from these pumps further contribute to their credibility. In conclusion, the twin casing slurry pump epitomizes a blend of innovative engineering, field-tested durability, and strategic design that meets contemporary industrial demands. Its dual casing technology significantly enhances its operational reliability and efficiency, proving to be an essential component in industries requiring robust slurry handling solutions. By integrating these pumps, businesses achieve a blend of performance, sustainability, and cost-effectiveness, reinforcing the pump's standing as an indispensable asset in advanced industrial applications.

Next:

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025