Дек . 10, 2024 19:54 Back to list

Top Manufacturers of High-Quality Centrifugal Dredge Pumps for Efficient Water Management

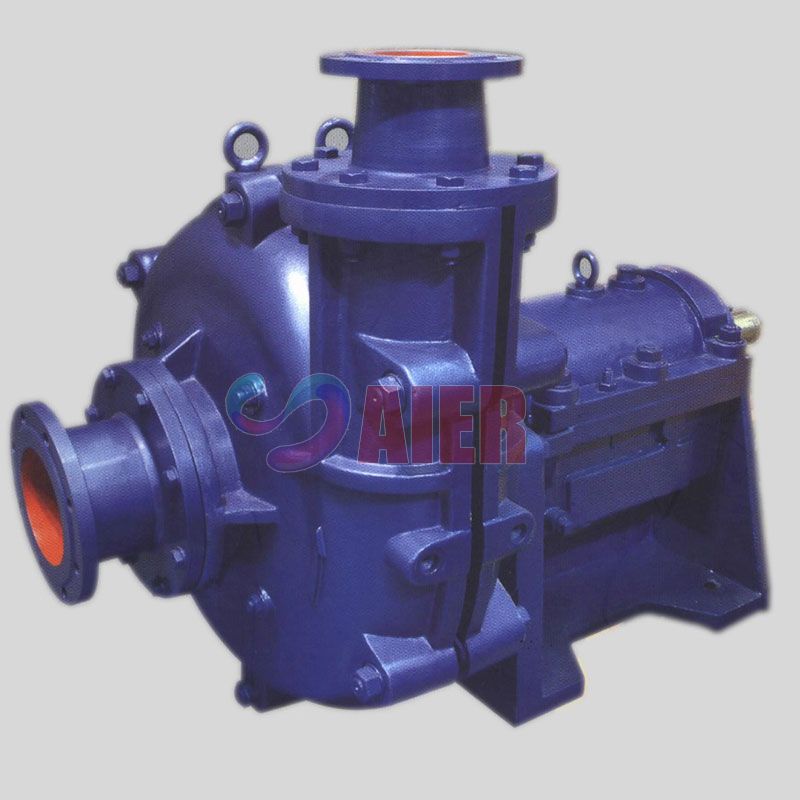

High-Quality Centrifugal Dredge Pump Factories A Comprehensive Overview

Centrifugal dredge pumps play a pivotal role in the dredging industry, facilitating the efficient movement of water, slurry, and sediments. As the demand for dredging operations increases, so does the necessity for high-quality centrifugal dredge pumps. This article delves into the factors that define the best pump factories, the technology involved, and the significance of quality assurance in manufacturing processes.

Importance of Centrifugal Dredge Pumps

Centrifugal dredge pumps are specifically designed to handle thick, viscous materials often encountered in dredging activities, including sand, silt, and mud. These pumps are capable of moving large volumes of materials over considerable distances. Their design allows for enhanced efficiency in mineral extraction, canal maintenance, and coastal protection projects. With advancements in technology, modern centrifugal pumps offer improved durability, reduced operational costs, and higher performance levels.

High-Quality Manufacturing Standards

The quality of any dredge pump begins at the manufacturing level

. High-quality centrifugal dredge pump factories prioritize the following aspects1. Raw Material Selection The durability of a pump largely depends on the materials used in its production. Reputable factories utilize high-quality metals and polymers resistant to wear, corrosion, and abrasion. Common materials include stainless steel, which offers resistance to rust, and various alloys tailored for specific operational conditions.

2. Advanced Engineering Cutting-edge engineering practices are essential in designing efficient and reliable pumps. High-quality factories often employ experienced engineers who apply principles of fluid dynamics and mechanical engineering to enhance performance. The design of the impeller, volute, and other components is crucial in optimizing flow rates and efficiency.

high quality centrifugal dredge pump factories

3. Precision Machining The manufacturing process requires precision machinery to ensure each component is produced to exact specifications. Advanced CNC (Computer Numerical Control) machining techniques enable factories to achieve high tolerances and consistency across production, resulting in superior pump performance.

4. Quality Control Rigorous quality control measures are essential in high-quality pump factories. Each pump undergoes various tests, including pressure tests, efficiency evaluations, and longevity assessments. Quality assurance protocols help identify and rectify defects before the pumps reach the market, ensuring reliability and performance.

Technological Integration

Modern centrifugal dredge pump factories widely adopt the latest technological innovations to enhance their manufacturing processes. Automation and robotics have streamlined production lines, resulting in increased efficiency and reduced human error. Additionally, simulation software is often used to model pump performance under various conditions, enabling producers to fine-tune designs before physical manufacturing.

Sustainability Practices

In today’s industrial landscape, sustainability is a critical consideration. High-quality centrifugal dredge pump factories are increasingly adopting eco-friendly practices. This includes using recycled materials in production, minimizing waste, and developing pumps that require less energy to operate. By focusing on sustainability, these factories contribute to environmentally responsible dredging practices, reducing the ecological impact of dredging activities.

Conclusion

High-quality centrifugal dredge pump factories are at the forefront of technological advancement and manufacturing excellence. By emphasizing superior materials, precision engineering, strict quality control, and sustainable practices, these factories are able to produce pumps that meet the rigorous demands of the dredging industry. As dredging activities continue to expand globally—fuelled by urban development and environmental management—the reliance on quality pumps will only grow. Investing in high-quality centrifugal dredge pumps from reputable factories not only ensures efficiency and reliability but also contributes to responsible environmental stewardship. For stakeholders in the dredging industry, understanding the significance of these manufacturing standards is crucial for making informed purchasing decisions that will enhance operational success.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025