Dec . 24, 2024 06:01 Back to list

Top Suppliers of Durable High-Quality Slurry Pump Casings for Optimal Performance

High-Quality Slurry Pump Body Casing Suppliers An Essential Guide

When it comes to managing the transportation of abrasive and viscous materials, slurry pumps play an essential role in various industries including mining, construction, and wastewater management. A critical component of these pumps is the body casing, which must withstand harsh conditions, resist wear, and ensure optimal performance. Therefore, selecting high-quality slurry pump body casing suppliers is vital for operational efficiency. This article explores the essential aspects to consider when looking for reliable suppliers, the benefits of high-quality casings, and the leading trends in the industry.

The Importance of Quality in Slurry Pump Body Casings

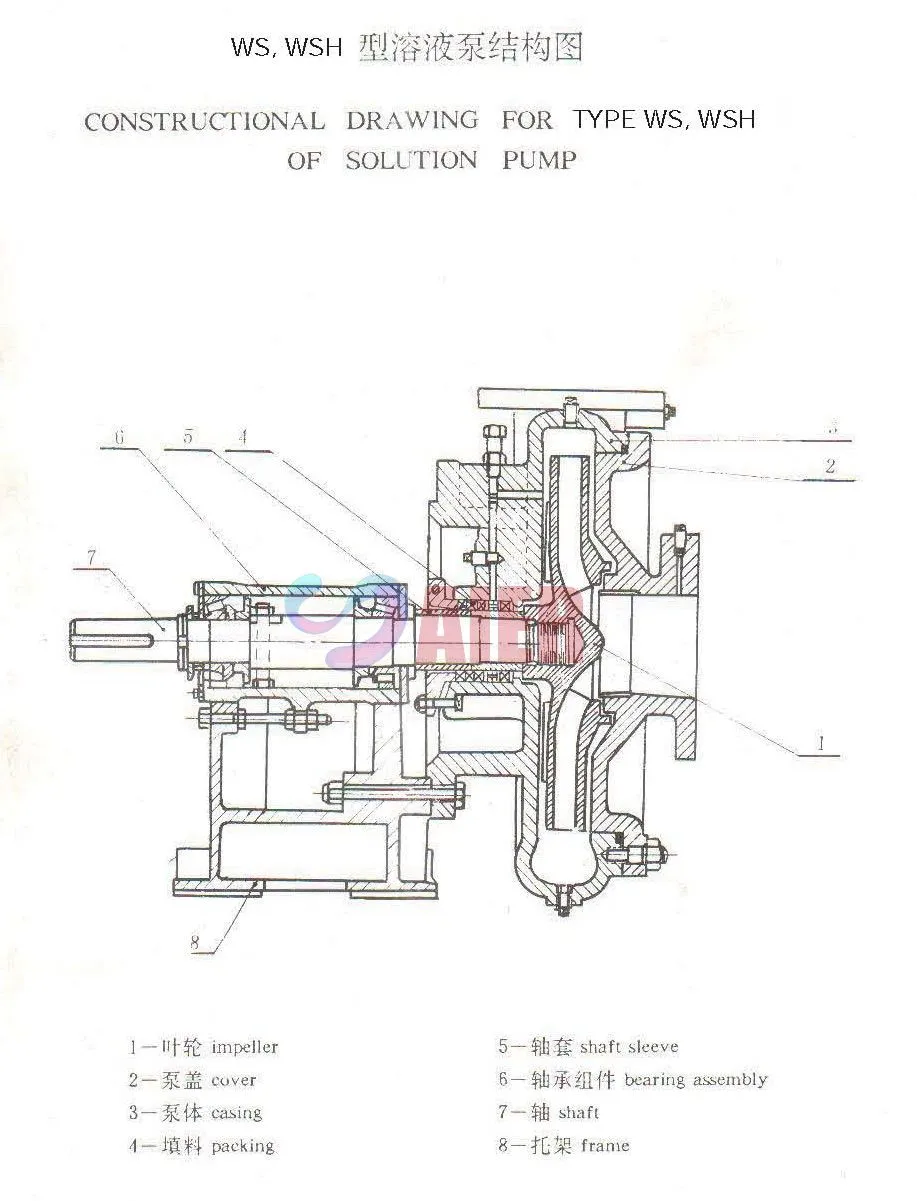

The body casing of a slurry pump is the structure that contains the pumping mechanism. It is subject to considerable stress due to heavy loads, abrasive materials, and high operational pressures. A robust and durable casing can significantly prolong the life of the pump, reduce maintenance costs, and improve overall performance. Hence, the choice of supplier and the quality of materials used in the manufacture of the body casing are crucial.

High-quality body casings are typically made from wear-resistant alloys, such as chrome-moly steel, which can effectively withstand the erosive nature of slurry. Moreover, quality control during manufacturing ensures that the casings maintain dimensional accuracy and consistency, which prevents operational issues such as leakage or pump failure.

What to Look for in Slurry Pump Body Casing Suppliers

1. Material Quality Choose suppliers that use high-grade materials specifically designed for slurry applications. This includes understanding the specific alloy compositions and their properties related to wear resistance and corrosion.

2. Manufacturing Standards Suppliers should adhere to globally recognized manufacturing standards. Certifications such as ISO 9001 provide assurance that the supplier follows stringent quality management systems.

3. Custom Solutions The ability to provide custom casing solutions tailored to specific applications is a significant advantage. Mines and industrial plants often operate under unique conditions that necessitate bespoke solutions.

4. Experience and Reputation Select suppliers with a proven track record in the industry. Experienced suppliers are more likely to understand the complexities of slurry transportation and the requirements for high-quality casings.

5. Technical Support Good suppliers offer technical assistance and support, helping end-users choose the right products and ensuring proper installation and maintenance.

6. After-Sales Service Reliable after-sales support, including warranties and servicing, is crucial for customer satisfaction and long-term relationship building.

Benefits of Partnering with Quality Suppliers

high quality slurry pump body casing suppliers

By partnering with high-quality slurry pump body casing suppliers, businesses can experience several benefits

- Reduced Downtime High-quality casings minimize the risk of pump failures, leading to less downtime and higher productivity.

- Cost Savings Investing in durable materials and quality manufacturing leads to reduced maintenance and replacement costs in the long run.

- Enhanced Efficiency Quality casings ensure optimal fluid flow, reducing energy consumption and improving the overall efficiency of slurry transport systems.

- Safety Improvements Reliable body casings reduce the risk of leaks and failures, thus enhancing the safety of operations in potentially hazardous environments.

Emerging Trends in Slurry Pump Manufacturing

The slurry pump industry is evolving with technology advancements and innovative materials. Some leading trends include

- 3D Printing Emerging manufacturing techniques, such as 3D printing, offer opportunities for producing complex designs that were previously impossible or too costly to manufacture.

- Smart Technology Integration of smart sensors and IoT (Internet of Things) technology is paving the way for smarter pumps which monitor performance and predict maintenance needs.

- Sustainability There is a growing focus on sustainable manufacturing practices, which not only reduce environmental impact but also improve efficiency.

Conclusion

The slurry pump body casing plays a vital role in the effectiveness and longevity of pumping systems. Choosing high-quality suppliers is fundamental for ensuring that the casings are robust, durable, and tailored to specific application needs. With an emphasis on material quality, proven experience, and technological advancements, companies can enhance their operations and achieve long-term reliability and efficiency. As the industry continues to innovate, staying informed about trends and supplier capabilities will equip businesses to make the best choices for their slurry transport needs.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025