Nov . 04, 2024 16:55 Back to list

Top Manufacturers of High-Quality A49 Slurry Pumps for Efficient Industrial Applications

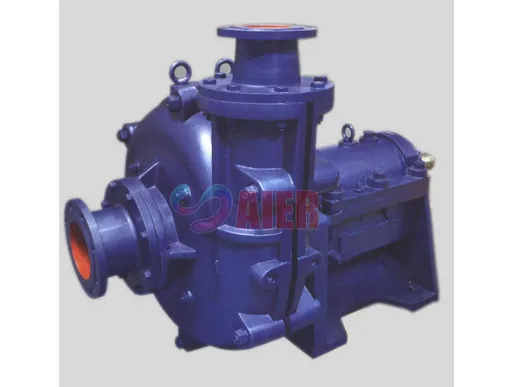

High Quality A49 Slurry Pump Factories A Comprehensive Overview

In the industrial world, the significance of efficient and reliable transportation of slurry cannot be overstated. Slurry, a mixture of liquid and solid particles, is found in various industries, including mining, construction, and wastewater treatment. Among the critical components that ensure the effective handling of slurry are pumps. One such notable pump is the A49 slurry pump, renowned for its strength, durability, and ability to handle abrasive materials. This article delves into the characteristics, advantages, and manufacturing processes of high-quality A49 slurry pump factories.

Understanding the A49 Slurry Pump

The A49 slurry pump is specifically designed for the demanding environments associated with the transfer of slurries. Its construction typically involves high-quality materials that can withstand erosion and corrosion. The A49 pump features a robust metal casing, impeller, and wear-resistant liners, which are essential for prolonging the pump’s lifespan. Its hydraulic design allows it to maintain optimal efficiency while minimizing energy consumption.

One of the most significant attributes of the A49 slurry pump is its versatility. It can handle a wide range of slurry types, including those with high solids content, highly viscous slurries, and abrasive materials. Due to its design, it can operate in both horizontal and vertical orientations, making it a flexible solution for various applications.

Advantages of High-Quality A49 Slurry Pumps

Purchasing a high-quality A49 slurry pump from reputable factories offers various advantages, including

1. Durability High-quality materials and precision engineering ensure that these pumps can withstand harsh conditions, reducing the frequency of repairs and downtime.

2. Efficiency Quality A49 pumps are designed for optimal hydraulic performance, resulting in lower energy consumption compared to lower-quality alternatives. This efficiency can translate into significant cost savings for businesses.

3. Reliability With robust construction, high-quality A49 pumps are less likely to fail, which is crucial in maintaining continuous processes in industries that rely on constant slurry transfer.

high quality a49 slurry pump factories

4. Customizability Many reputable manufacturers provide customization options to cater to specific needs, allowing companies to design pumps that perfectly fit their operational requirements.

5. Support and Maintenance Well-established factories often provide comprehensive warranties and customer support, ensuring that businesses receive assistance beyond the purchase.

Manufacturing Processes in A49 Slurry Pump Factories

The production of high-quality A49 slurry pumps involves several critical steps, each vital to ensuring the final product meets industry standards.

1. Material Selection Factories usually source high-grade materials such as stainless steel and high-chromium alloy for the pump components. The choice of materials directly impacts the pump's resistance to wear and chemical aggressiveness.

2. Precision Machining CNC (Computer Numerical Control) technology is commonly used to achieve precise dimensions and tolerances. This step is crucial for ensuring that the pump components fit together seamlessly, reducing the potential for leakage and increasing efficiency.

3. Assembly Skilled technicians assemble the pumps, ensuring that each component, from impellers to casings, is meticulously aligned and well-fitted. Quality control measures are often implemented throughout this stage to catch any defects.

4. Testing Before leaving the factory, each A49 slurry pump undergoes rigorous testing. This includes checking for performance metrics such as flow rate, pressure, and operational efficiency. Factories adhere to international standards to guarantee their products meet quality expectations.

5. Delivery and Support After comprehensive testing, the pumps are packaged and delivered to clients. Many factories offer installation support, as well as maintenance services to ensure that the pumps operate at peak performance throughout their lifecycle.

In conclusion, the significance of high-quality A49 slurry pump factories in the industrial sector cannot be understated. By focusing on durability, efficiency, and reliability, these manufacturers provide essential equipment that enhances operational performance across various industries. The intricate manufacturing processes, combined with a commitment to quality and customer support, ensures that industries can rely on A49 pumps as a cornerstone of their slurry handling systems. Investing in high-quality A49 slurry pumps is an investment in operational excellence.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025