Oct . 17, 2024 15:30 Back to list

China Manufacturer of Rubber Parts for Vertical Slurry Sump Pumps and Related Equipment

China Vertical Slurry Sump Pump Rubber Parts Manufacturer

In the world of industrial pumps, the need for reliability and durability in various environments is paramount. Vertical slurry sump pumps play a crucial role in transporting abrasive mixtures in mining, mineral processing, and industrial applications. Among the essential components of these pumps are the rubber parts, designed to withstand harsh conditions while maintaining performance. In China, manufacturers specializing in vertical slurry sump pump rubber parts have emerged as key players in ensuring operational efficiency across various industries.

Importance of Rubber Parts in Vertical Slurry Sump Pumps

Rubber parts, such as seals, liners, and wear pads, are integral to the functionality of vertical slurry sump pumps. They provide essential protection against the erosive and corrosive nature of slurries, which often contain solids and abrasive materials. The characteristics of rubber, including its flexibility, resilience, and resistance to wear, make it an ideal choice for these applications.

The primary function of rubber components in slurry pumps includes preventing leaks, reducing wear on metal parts, and ensuring efficient sealing against the high pressures and flow rates typically encountered in pump operations. This is particularly critical in environments where downtime can result in significant financial losses due to interrupted production processes.

The Manufacturing Landscape in China

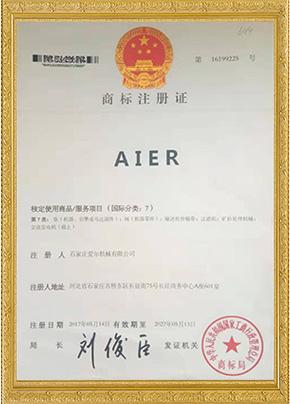

China has established itself as a global hub for the manufacturing of industrial components, including rubber parts for vertical slurry sump pumps

. With a combination of advanced manufacturing techniques, skilled labor, and cost-effective production processes, Chinese manufacturers are well-positioned to cater to both domestic and international markets.The country’s manufacturing sector benefits from the use of state-of-the-art machinery and quality control measures that meet international standards. Many manufacturers have also adopted innovative technologies, such as computer-aided design (CAD) and simulation software, to enhance product design and optimize performance.

china vertical slurry sump pump rubber parts manufacturer

Quality Control and Standards

Quality control is a critical aspect of the manufacturing process for rubber parts. Reputable Chinese manufacturers often adhere to international quality standards, such as ISO 9001, ensuring their products meet stringent requirements for performance and reliability. Rigorous testing procedures, including abrasion tests and tensile strength assessments, are conducted to validate the performance of rubber components under various operational conditions.

Additionally, many manufacturers source high-quality raw materials that are specifically formulated for use in slurry applications. This emphasis on material quality ensures that the resultant rubber parts offer superior durability and resistance to wear, ultimately translating into longer service life and reduced maintenance costs for the end-users.

Customization and Innovation

One of the notable advantages of partnering with Chinese manufacturers is their ability to provide customized solutions tailored to specific operational needs. Clients can collaborate with manufacturers to design rubber parts that suit particular pump models or unique application requirements. This level of customization often leads to improved performance outcomes and greater customer satisfaction.

Furthermore, ongoing research and development efforts within the industry drive continuous innovation. Manufacturers are exploring new rubber compounds, such as those that enhance chemical resistance or provide better performance in extreme temperatures, to meet the evolving demands of the market. By investing in R&D, Chinese manufacturers are not only improving their product offerings but also contributing to the global advancement of pump technology.

Conclusion

The role of Chinese manufacturers in the production of rubber parts for vertical slurry sump pumps cannot be overstated. With their focus on quality, customization, and innovation, they are well-equipped to support various industries that rely on effective slurry handling solutions. As global demand for reliable and efficient pumping systems continues to grow, China’s expertise in manufacturing high-quality rubber components positions it as a leader in the field. Collaborating with these manufacturers enables businesses to enhance their operational efficiency and maintain high standards in their pumping applications, ultimately leading to improved productivity and profitability.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025