ส.ค. . 04, 2024 02:56 Back to list

Premium Wastewater Pumps for Industrial Applications in Wastewater Treatment Facilities and Factories

High-Quality Pumps for Wastewater Treatment Factories

In the realm of wastewater treatment, the efficiency and reliability of pumping systems play a crucial role in ensuring the successful operation of treatment facilities. Wastewater factories rely on high-quality pumps to move, transfer, and treat wastewater effectively. The selection of the right pump can significantly affect the overall performance of the facility, impacting both operational costs and environmental compliance.

Wastewater is a complex mixture that can contain solids, chemicals, and biological matter, which necessitates the use of robust pumping solutions designed to handle such challenges. High-quality pumps for wastewater treatment factories must be capable of withstanding harsh conditions, including corrosive environments and the presence of abrasive particles. These pumps often feature materials such as stainless steel, ductile iron, or specialized polymers that resist corrosion and wear, ensuring a longer lifespan and reduced maintenance costs.

High-Quality Pumps for Wastewater Treatment Factories

Another common type of pump found in wastewater treatment facilities is the centrifugal pump. Known for their efficiency and adaptability, centrifugal pumps utilize a rotating impeller to move fluids and can handle a broad range of flow rates and pressures. These pumps are suitable for transporting both clean and wastewater and can be easily integrated into existing systems. Their versatility makes them an invaluable asset in the complex operations of wastewater treatment factories.

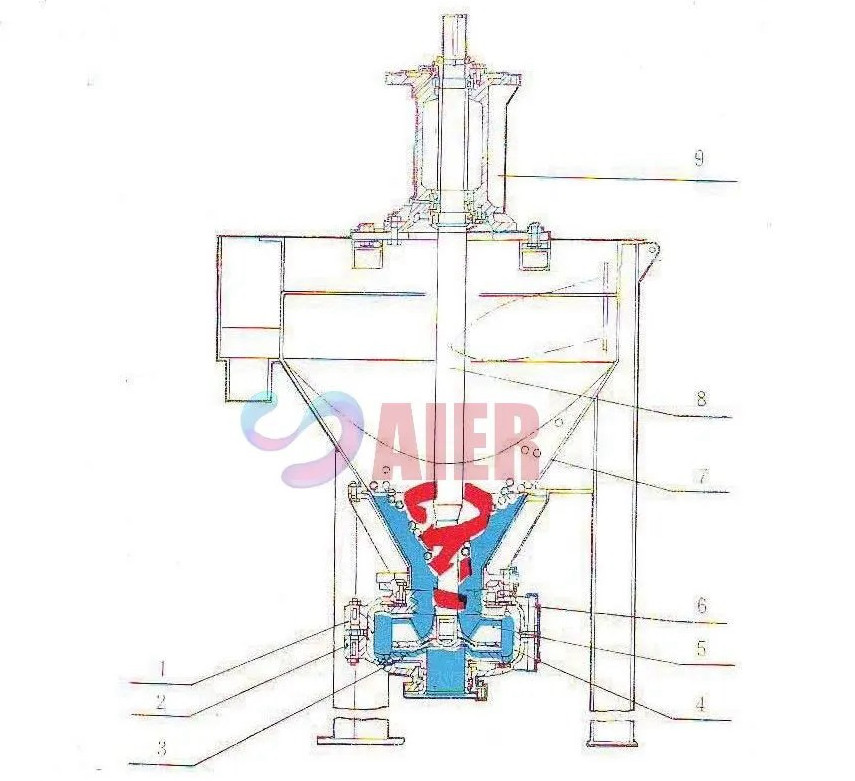

high quality pump for wastewater factories

In addition to the pump types, advanced technologies such as variable frequency drives (VFDs) integrate with pumping systems, enhancing their efficiency. VFDs allow for real-time adjustments to pump speed based on demand, resulting in energy savings and optimized performance. This technology responds dynamically to flow requirements, reducing wear on the pumps and lowering energy costs – a critical consideration for wastewater treatment operations that often struggle with high operational expenses.

The importance of selecting a pump with a high degree of reliability cannot be overstated. Downtime due to pump failures can lead to significant operational disruptions and can jeopardize compliance with environmental regulations. Investing in high-quality pumps that come from reputable manufacturers ensures not only durability but also the availability of technical support and spare parts. When choosing pumps, facilities should also consider factors like ease of installation, maintenance requirements, and overall system compatibility.

To further enhance the performance of pumping systems, routine maintenance and monitoring practices should be put into place. Regular inspections and preventive maintenance can identify potential issues before they lead to failure, ensuring the pump operates at optimal efficiency. Modern monitoring technologies, such as IoT sensors and predictive maintenance software, can provide real-time data about pump performance, enabling wastewater treatment facilities to respond proactively to issues.

In conclusion, the role of high-quality pumps in wastewater treatment factories is paramount. With the right pump selection, facilities can achieve efficient operation, maintain regulatory compliance, and minimize environmental impact. Emphasizing quality, durability, and advanced technology will empower wastewater treatment plants to effectively manage the challenges presented by wastewater, ultimately leading to better outcomes for both the environment and public health. Investing in reliable, high-quality pumps is not just a technical choice; it is a commitment to sustainable water management and community well-being.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025