Nov . 24, 2024 04:18 Back to list

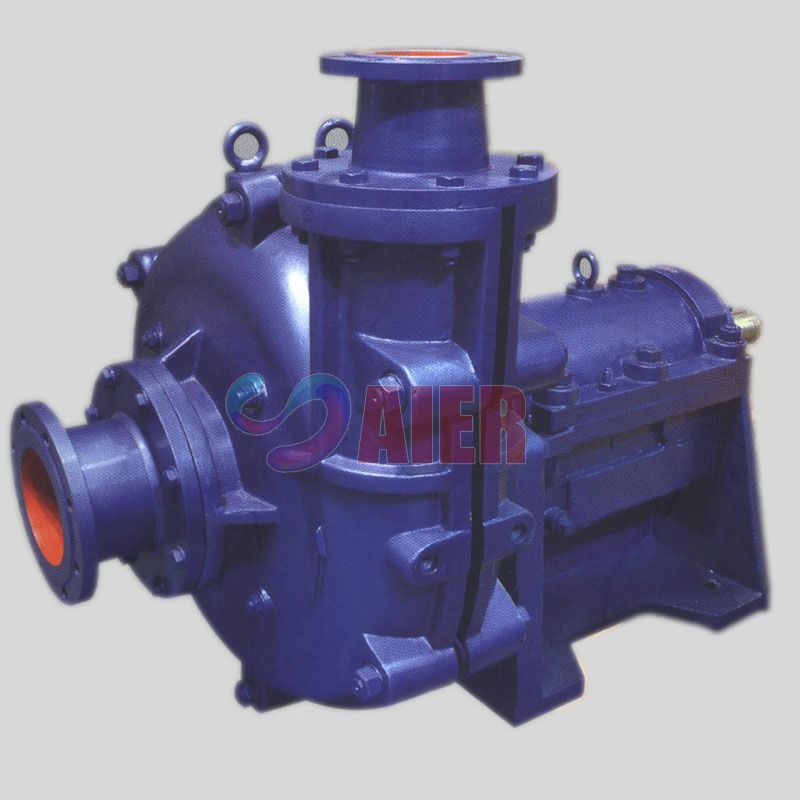

high quality centrifugal slurry pump spare parts

High Quality Centrifugal Slurry Pump Spare Parts An Overview

Centrifugal slurry pumps play a critical role in various industries, particularly in mining, chemical processing, and wastewater treatment. These pumps are designed to handle abrasive and viscous slurries, making them essential for transporting materials that can be tough on conventional pumps. However, to ensure optimal performance and longevity, the quality of spare parts used in these pumps is of utmost importance. This article explores the significance of high-quality centrifugal slurry pump spare parts and their impact on operational efficiency.

Understanding Centrifugal Slurry Pumps

Centrifugal slurry pumps operate by converting rotational energy from the pump impeller into hydrodynamic energy. This allows them to effectively transport slurries, which consist of solid particles suspended in liquid. Given the nature of the materials they handle, these pumps are often subjected to extreme conditions that can lead to wear and tear. As such, having access to high-quality spare parts is crucial for maintaining their functionality.

The Importance of High-Quality Spare Parts

1. Durability and Longevity One of the primary advantages of using high-quality spare parts is their enhanced durability. Components such as impellers, casing, and shafts made from superior materials are more resistant to abrasion and corrosion. This resistance significantly reduces the frequency of replacements and maintenance downtime. For industries that rely on continuous operations, this translates to cost savings and improved workflows.

high quality centrifugal slurry pump spare parts

2. Performance Efficiency High-quality spare parts ensure that pumps operate at their designed efficiency. Poorly made or incompatible parts can lead to inefficiencies such as reduced flow rates or increased energy consumption. Quality components contribute to maintaining optimal pump curves, which are critical for ensuring that the pump can handle the intended slurry characteristics without strain.

3. Safety Considerations In applications involving hazardous materials, the integrity of pumping systems is vital for safety. The failure of a pump or its components due to inferior spare parts can lead to spills or leaks, posing risks to personnel and the environment. Investing in high-quality parts helps mitigate these risks, ensuring that the pumping systems function safely under high-stress conditions.

4. Cost-Effectiveness While it may be tempting to purchase cheaper parts to reduce upfront costs, the long-term expenses associated with these lower-quality components can be much higher. Frequent breakdowns, repairs, and replacements can accumulate over time, making high-quality parts a more economical choice in the long run.

5. Technical Support and Warranty Reputable manufacturers of high-quality spare parts often provide extensive technical support and warranties. This means that in the event of an issue, operators can receive guidance and assurance that they are investing in reliable components, decreasing the potential for operational disruptions.

Conclusion

In conclusion, high-quality centrifugal slurry pump spare parts are integral to the efficiency and reliability of slurry pumping systems. The investment in durable, efficient, and safe components not only enhances the performance and longevity of the pumps but also contributes to overall operational cost savings. Industries that prioritize the use of quality spare parts will likely experience fewer issues and better performance, securing their productivity in the competitive marketplace. As such, operators should always consider the long-term benefits of selecting high-quality replacement components for their centrifugal slurry pumps.

-

Submersible Well Pump Manufacturer: Reliable & Efficient Solutions

NewsJul.22,2025

-

China Slurry Pump Volute Liner Factory | Durable Spare Parts

NewsJul.21,2025

-

Premium Studs for Cover & Frame Plates | Corrosion-Resistant

NewsJul.20,2025

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025