డిసెం . 31, 2024 01:48 Back to list

Top-Quality Submersible Slurry Pump Manufacturing Facility for Industry Needs

High-Quality Submerged Slurry Pump Manufacturing An Overview

In the realm of industrial operations, the importance of reliable equipment cannot be overstated, particularly when it comes to pumping solutions. Among these, high-quality submerged slurry pumps play a crucial role in various sectors, including mining, construction, and wastewater management. This article delves into the intricacies of submerged slurry pump manufacturing, highlighting the significance of quality and innovation in production.

Understanding Submerged Slurry Pumps

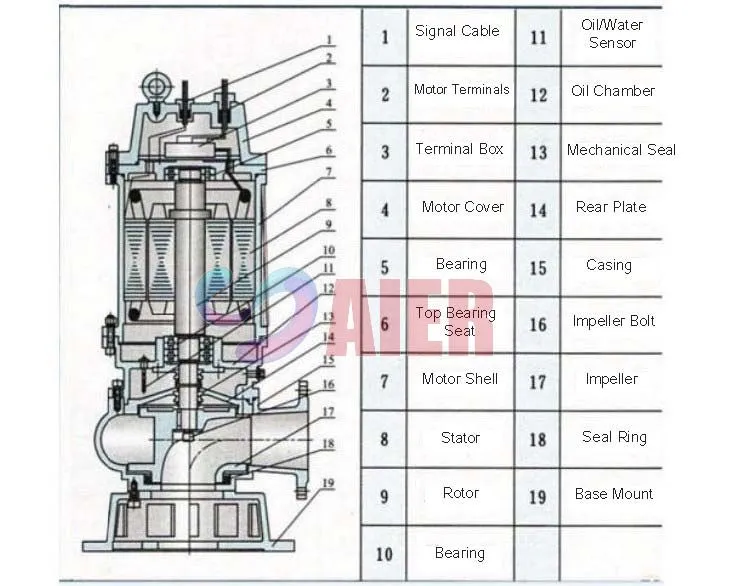

Submerged slurry pumps are designed to handle highly viscous fluids and mixtures containing solid particles. Unlike standard pumps, submerged slurry pumps operate while immersed in the fluid being pumped, making them particularly effective for applications where the fluid source is deep or where space is constrained. Their design minimizes cavitation and wear, ensuring optimal performance even in challenging conditions.

The construction typically features robust materials capable of withstanding corrosion and erosion. Common materials include various grades of stainless steel and rubber linings, ensuring longevity and resistance against abrasive particles that can damage equipment over time.

The Importance of Quality in Manufacturing

When it comes to the production of submerged slurry pumps, quality assurance is paramount. High-quality pumps contribute to operational efficiency, reduce the frequency of maintenance and replacements, and ultimately enhance the productivity of industrial processes. Manufacturers adhere to strict quality control standards, often employing advanced technologies and methodologies to ensure that every pump supplied meets or exceeds industry standards.

Utilizing precision machining techniques and rigorous testing protocols, manufacturers can verify the performance characteristics of their pumps, such as flow rate, pressure, and wear resistance. This commitment to quality not only ensures high operational reliability but also builds trust with clients, who rely on these pumps for critical applications.

The Role of Innovation and Technology

high quality submerged slurry pump factory

The manufacturing sector is undergoing rapid changes owing to advancements in technology. Innovations such as computer-aided design (CAD) and computational fluid dynamics (CFD) enable manufacturers to create more efficient and effective slurry pumps. These technologies allow for better visualization and modeling of pump performance, leading to improvements in design and functionality.

Additionally, the incorporation of smart technology into submerged slurry pumps is gaining traction. Sensors can be integrated into pumps to monitor performance in real time, providing valuable data that can be used to predict maintenance needs, enhance operational efficiency, and reduce downtime.

Environmental Considerations

In today's industrial landscape, sustainability is a growing concern. Quality submerged slurry pump manufacturers are increasingly focused on minimizing their environmental impact. This involves using eco-friendly materials, designing energy-efficient pumps, and implementing manufacturing processes that reduce waste and emissions. By prioritizing sustainable practices, these manufacturers not only contribute to environmental conservation but also appeal to a market that values corporate responsibility.

Future Trends in Submerged Slurry Pump Manufacturing

As industries evolve, so do the demands placed on submerged slurry pumps. The future of slurry pump manufacturing is likely to be shaped by trends such as increased automation, enhanced materials technology, and further integration of smart sensors. Manufacturers who adapt to these changes and remain committed to quality will be well-positioned to meet the challenges and demands of the future.

Conclusion

High-quality submerged slurry pumps are essential components in various industrial applications, with their success reliant on meticulous manufacturing standards and innovative technologies. As the industry continues to advance, the focus on quality and sustainability will remain integral to the growth and evolution of submerged slurry pump manufacturers. By prioritizing these aspects, businesses can ensure that their operations remain efficient, reliable, and environmentally responsible.

-

Small Dredger and Marine Pontoon- Aier Machinery Hebei Co., Ltd|Cost-Effective Solutions&High-Efficiency Dredging

NewsAug.05,2025

-

Submersible Pump Impeller Manufacturer | GPT-4 Turbo Series

NewsAug.05,2025

-

Premium Warman Slurry Pump Mechanical Seal - Leak-Proof

NewsAug.04,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Gold Mining Equipment, Sand Dredging Machines

NewsAug.03,2025

-

Small Dredger & Marine Pontoon-Aier Machinery Hebei Co., Ltd|Industrial Equipment&Mining Machinery

NewsAug.03,2025

-

Small Dredger & Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Gold Mining Equipment, Industrial Dredging

NewsAug.03,2025