ஜன . 02, 2025 10:24 Back to list

single stage vertical slurry pump manufacturers

Understanding Single Stage Vertical Slurry Pumps A Manufacturer's Perspective

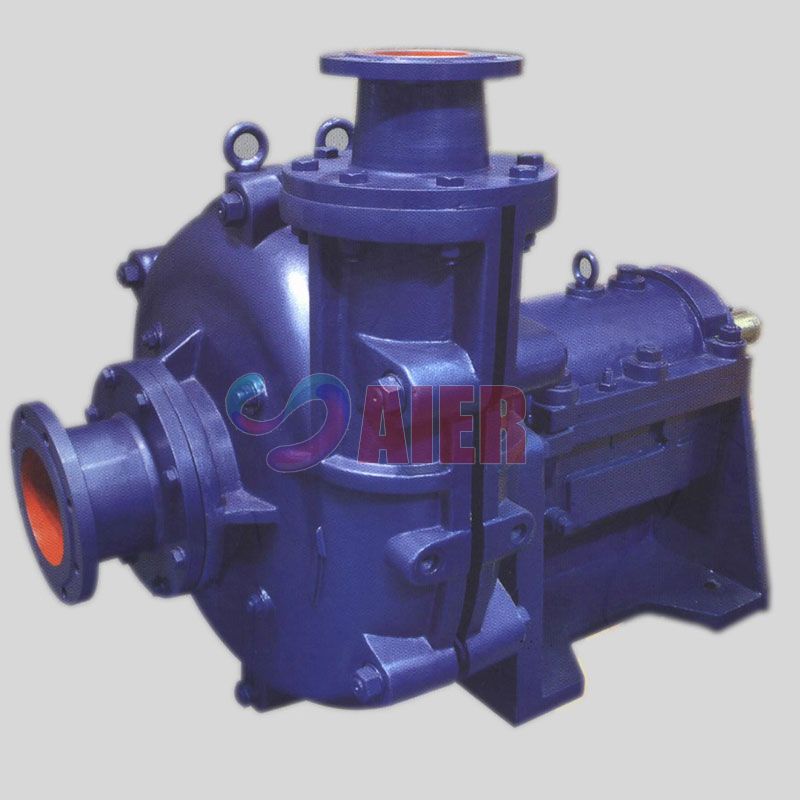

Single-stage vertical slurry pumps are crucial in various industries, including mining, chemical processing, and wastewater management. They are designed to handle abrasive and viscous slurries, making them essential for applications where traditional pumps may falter. In this article, we will delve into what makes these pumps unique and how manufacturers ensure their efficacy and durability.

What is a Single Stage Vertical Slurry Pump?

A single-stage vertical slurry pump is characterized by its vertical orientation and design to operate in a single pumping stage. These pumps are often utilized for transporting slurries, which consist of solid particles suspended in liquids. The vertical design allows these pumps to be installed in deep pits or sumps, effectively reducing the footprint required for operation. Additionally, this configuration ensures that the pump can operate effectively underwater, extending its capabilities in various applications.

Key Features and Benefits

1. Efficient Solids Handling Single-stage vertical slurry pumps are specifically engineered to handle abrasive materials and solids up to a certain size. This is crucial in industries like mining, where materials like ores and tailings contain large particles.

2. Durability Manufacturers typically use high-quality materials, such as high-chrome alloys and rubber linings, to enhance wear resistance. This durability extends the pump's lifespan, reducing maintenance costs and downtime.

3. Compact Design The vertical orientation of these pumps allows for more efficient use of space. This characteristic is particularly beneficial in settings with limited space, such as underground mines or smaller industrial facilities.

4. Versatility These pumps can be used in a wide range of applications, from transporting slurry in mining operations to moving wastewater in treatment plants. Their adaptability makes them a valuable addition to any industrial operation.

5. Low Maintenance Requirements Due to their robust construction, single-stage vertical slurry pumps often require less maintenance compared to other types of pumps. This attribute is highly attractive to manufacturers and operators alike, as it minimizes operational interruptions.

single stage vertical slurry pump manufacturers

The Manufacturing Process

Manufacturing single-stage vertical slurry pumps involves several critical stages

1. Material Selection As mentioned earlier, the choice of materials is vital. Manufacturers select materials based on the specific application and working environment to ensure durability and performance.

2. Design Engineering Engineering teams utilize advanced software and design principles to create efficient pump geometries. Computational Fluid Dynamics (CFD) simulations may be employed to optimize flow and minimize energy consumption.

3. Fabrication Skilled technicians and advanced machinery are employed to fabricate the pump components. This may include casting, machining, and assembling various parts with precision to ensure optimal performance.

4. Quality Control Rigorous testing and quality control processes are implemented to adhere to industry standards. Each pump undergoes thorough inspections to ensure it meets performance specifications and safety regulations.

5. Customization Many manufacturers offer customization options, allowing clients to tailor the pump specifications to their specific needs. This can include variations in impeller design, materials, and dimensions.

Conclusion

Single-stage vertical slurry pumps play a vital role in ensuring the successful operation of various industries. With their robust design, efficient performance, and low maintenance requirements, these pumps are indispensable for dealing with challenging slurry transport tasks. As manufacturers continue to innovate and improve upon their designs, the efficiency and reliability of these pumps will only increase, further solidifying their position in industrial applications. Industry stakeholders must remain informed about the latest advancements to make educated decisions when selecting the right pump for their operational needs.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025