பிப் . 17, 2025 15:40 Back to list

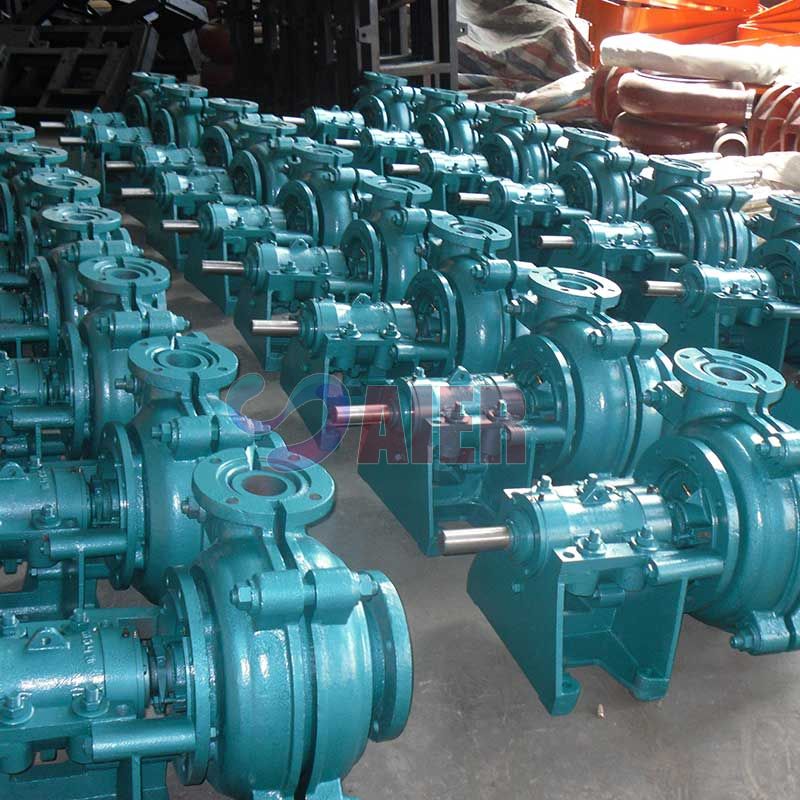

High Chromium Alloy Wet Ends

In the world of slurry pumps, the difference between high performance and frequent downtime often hinges on a critical yet overlooked component the wetted parts. These parts, directly exposed to the abrasive and sometimes corrosive materials being pumped, dictate the pump's lifespan, efficiency, and reliability. Investing in high-quality wetted parts is paramount for operations that demand continuous and trouble-free processing.

Customers frequently share testimonials that emphasize the superiority of high-quality wetted parts in minimizing maintenance costs. Reduced frequency in part replacement decreases the downtime required for maintenance, directly correlating with increased productivity and reduced operational costs. For instance, a mining operation that upgraded to high-quality wetted parts reported a 25% boost in yearly output by minimizing downtime and minimizing unexpected failures. In light of trustworthiness, selecting a reputable supplier for wetted parts is paramount. A trustworthy supplier not only provides high-quality parts but also offers comprehensive support from installation to maintenance advice. The assurance of after-sales service, with experts ready to assist in troubleshooting and optimizing pump performance, underscores the decision to choose high-grade parts. Moreover, advancements in technology have enabled manufacturers to produce customizable solutions tailored to specific operational demands. The advent of 3D CAD modeling and simulations allows for the creation of customized wetted parts that fit perfectly within existing systems, enhancing efficiency, and reducing energy consumption. These tailored solutions offer a combination of optimized flow dynamics and minimal power consumption. In conclusion, the benefits of investing in high-quality wetted parts for slurry pumps extend far beyond the initial cost. The efficiency, reliability, and longevity they bring to operations make them indispensable for companies seeking to maintain competitive advantages in demanding industries. With expert guidance, data-backed assurances, and customizable solutions, high-quality wetted parts for slurry pumps represent not just a replacement, but a strategic enhancement to operational outputs.

Customers frequently share testimonials that emphasize the superiority of high-quality wetted parts in minimizing maintenance costs. Reduced frequency in part replacement decreases the downtime required for maintenance, directly correlating with increased productivity and reduced operational costs. For instance, a mining operation that upgraded to high-quality wetted parts reported a 25% boost in yearly output by minimizing downtime and minimizing unexpected failures. In light of trustworthiness, selecting a reputable supplier for wetted parts is paramount. A trustworthy supplier not only provides high-quality parts but also offers comprehensive support from installation to maintenance advice. The assurance of after-sales service, with experts ready to assist in troubleshooting and optimizing pump performance, underscores the decision to choose high-grade parts. Moreover, advancements in technology have enabled manufacturers to produce customizable solutions tailored to specific operational demands. The advent of 3D CAD modeling and simulations allows for the creation of customized wetted parts that fit perfectly within existing systems, enhancing efficiency, and reducing energy consumption. These tailored solutions offer a combination of optimized flow dynamics and minimal power consumption. In conclusion, the benefits of investing in high-quality wetted parts for slurry pumps extend far beyond the initial cost. The efficiency, reliability, and longevity they bring to operations make them indispensable for companies seeking to maintain competitive advantages in demanding industries. With expert guidance, data-backed assurances, and customizable solutions, high-quality wetted parts for slurry pumps represent not just a replacement, but a strategic enhancement to operational outputs.

Next:

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025