ஜன . 20, 2025 03:48 Back to list

G10083A05 high chrome throatbush

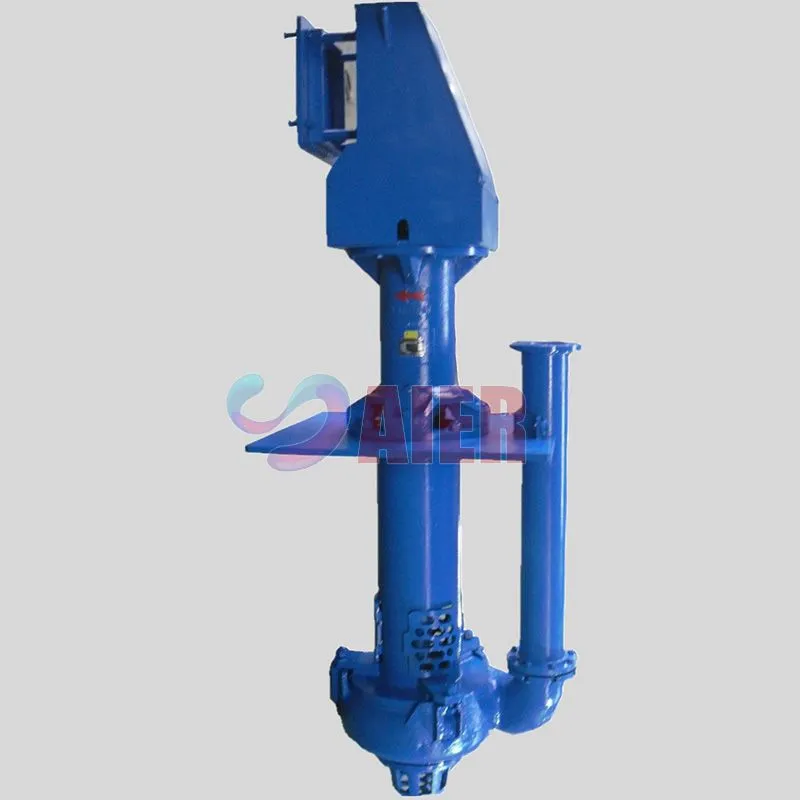

Building a dredge pump is a task that combines intricate engineering expertise with real-world application savvy. As one navigates the technical nuances of creating a pump designed specifically for dredging purposes, it becomes imperative to leverage both professional knowledge and practical experience to ensure its effectiveness, durability, and reliability.

Once the pump design is optimized, the manufacturing process plays a critical role. Precision casting and machining are essential to produce components that meet exact design specifications. Any deviation may result in operational inefficiency or premature failure, thereby eroding the trust users place in the product. Quality assurance mechanisms, including rigorous testing protocols, help reinforce the reliability of the dredge pump, ensuring it can withstand high-pressure conditions and abrasive materials. Field testing further verifies the pump's performance. Real-world application tests under actual dredging conditions provide invaluable feedback, showcasing whether the theoretical calculations hold up in practice. Engineers often work closely with operators to fine-tune the pump's settings, ensuring it functions at its utmost potential, gaining actionable data that returns to influence future designs. In addition to building the pump, consideration of the broader system is paramount. Successful integration with existing dredging setups, compatibility with chosen drive units, and understanding the environmental regulations surrounding dredging operations contribute to the pump's overall success and market acceptance. Emphasizing expertise, the insights into the most minute aspects of engineering and material science underscoring dredge pump design establish its authority in the field. The trust built by manufacturers through consistent quality delivery enforces the underlying principle that a well-built dredge pump is not merely a product but a pivotal component in complex ecological and industrial operations. In conclusion, the confluence of expert engineering, strategic material selection, and real-world reliability testing culminates in a dredge pump that stands the test of time and environment. Forums and discussions around dredge pump experiences further enhance knowledge sharing among professionals, cementing the industry's reputation built on both expertise and trust.

Once the pump design is optimized, the manufacturing process plays a critical role. Precision casting and machining are essential to produce components that meet exact design specifications. Any deviation may result in operational inefficiency or premature failure, thereby eroding the trust users place in the product. Quality assurance mechanisms, including rigorous testing protocols, help reinforce the reliability of the dredge pump, ensuring it can withstand high-pressure conditions and abrasive materials. Field testing further verifies the pump's performance. Real-world application tests under actual dredging conditions provide invaluable feedback, showcasing whether the theoretical calculations hold up in practice. Engineers often work closely with operators to fine-tune the pump's settings, ensuring it functions at its utmost potential, gaining actionable data that returns to influence future designs. In addition to building the pump, consideration of the broader system is paramount. Successful integration with existing dredging setups, compatibility with chosen drive units, and understanding the environmental regulations surrounding dredging operations contribute to the pump's overall success and market acceptance. Emphasizing expertise, the insights into the most minute aspects of engineering and material science underscoring dredge pump design establish its authority in the field. The trust built by manufacturers through consistent quality delivery enforces the underlying principle that a well-built dredge pump is not merely a product but a pivotal component in complex ecological and industrial operations. In conclusion, the confluence of expert engineering, strategic material selection, and real-world reliability testing culminates in a dredge pump that stands the test of time and environment. Forums and discussions around dredge pump experiences further enhance knowledge sharing among professionals, cementing the industry's reputation built on both expertise and trust.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025