Nov . 10, 2024 02:53 Back to list

China Slurry Pump Bearing Assembly Manufacturers and Their Production Excellence

An Overview of Slurry Pump Bearing Assembly Factories in China

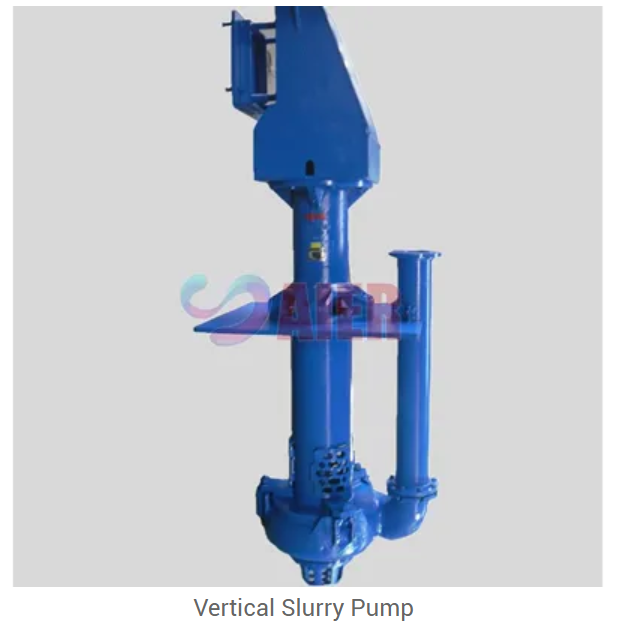

Slurry pumps are essential components in various industries, including mining, metallurgy, and construction. Their primary function is to transfer a mixture of solids and liquids, known as slurry, from one point to another. The effectiveness and longevity of these pumps largely depend on the quality of their bearing assemblies. In this context, Chinese factories specializing in slurry pump bearing assembly have gained significant attention for their production capabilities and technological advancements.

The Importance of Bearing Assemblies in Slurry Pumps

Bearing assemblies play a crucial role in the operation of slurry pumps. They are responsible for supporting the rotating shaft, guiding it, and maintaining its alignment while minimizing friction and wear. Given the harsh environments where slurry pumps often operate—exposed to abrasive materials and high loads—it is essential for these bearing assemblies to be robust and reliable. High-quality bearings can greatly enhance the pump's efficiency and lifespan, making them a critical component in ensuring optimal performance in industrial applications.

Manufacturing Landscape in China

China has established itself as a global leader in manufacturing slurry pumps and their components, including bearing assemblies. The country is home to numerous factories specializing in various aspects of slurry pump production. These facilities often leverage advanced manufacturing technologies, such as CNC machining, precision forging, and automated assembly lines, to produce high-quality products.

One of the key advantages of manufacturing in China is cost efficiency. Due to lower labor costs and bulk production capabilities, Chinese factories can offer competitive pricing without sacrificing quality. This affordability has made Chinese slurry pump bearing assemblies appealing to global buyers, from small enterprises to large multinational corporations.

Quality Assurance and Standards

Despite concerns about quality associated with mass production in some regions, many Chinese manufacturers have adopted stringent quality control measures. International standards such as ISO 9001 have been widely implemented in manufacturing processes, ensuring that products meet specific quality benchmarks. These factories often invest in modern testing facilities to perform rigorous assessments on their bearing assemblies, subjecting them to operational stress simulations and failure analysis.

china slurry pump bearing assembly factories

Moreover, certain factories focus on research and development, creating innovative bearing designs that improve performance under challenging conditions. Such investments in R&D not only enhance the durability of the products but also contribute to advancing slurry pump technology as a whole.

Environmental Considerations

With increasing global emphasis on sustainability and environmental responsibility, many Chinese manufacturers are also adopting eco-friendly practices. This includes utilizing environmentally safe materials for production and implementing waste reduction techniques in their manufacturing processes. Some factories are also exploring ways to utilize renewable energy sources, further aligning their operations with global sustainability goals.

Global Reach and Market Demand

The demand for slurry pumps and their bearing assemblies continues to grow, particularly in emerging markets where industrialization is on the rise. Chinese manufacturers have captured a substantial share of the global market due to their ability to supply high-quality products at competitive prices. Their export strategies often include establishing a network of partnerships with distributors and OEMs (Original Equipment Manufacturers) worldwide. This approach ensures that their products reach a diverse clientele across various sectors.

Additionally, many Chinese factories are now focusing on enhancing their customer service and support capabilities. By providing technical assistance and efficient after-sales services, they aim to build long-term relationships with their clients, which can lead to repeat business and customer loyalty.

Conclusion

As the demand for slurry pumps and their associated components, including bearing assemblies, continues to rise, Chinese factories are poised to remain at the forefront of this industry. Their combination of cost-effective manufacturing, commitment to quality, and increasing focus on sustainability makes them key players in the global market. For businesses considering sourcing slurry pump bearing assemblies, exploring partnerships with reputable Chinese manufacturers could provide significant advantages in terms of both performance and cost efficiency.

-

Small Dredger & Marine Pontoon Solutions - Aier Machinery | High Efficiency & Durability

NewsAug.10,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd.|Dredging Equipment, Gold Mining Solutions

NewsAug.10,2025

-

Durable Submersible Well Pump Manufacturer | Quality Pumps & Parts

NewsAug.10,2025

-

Small Dredger and Marine Pontoon Solutions-Aier Machinery|Durable Industrial Dredging&Efficient Material Handling

NewsAug.09,2025

-

Innovative Small Dredgers and Marine Pontoon Solutions from Aier Machinery Hebei Co., Ltd.-Reliable Dredging Equipment&Customizable Marine Pontoons

NewsAug.09,2025

-

Small Dredger and Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Marine Dredge Pump Manufacturers,Gold Dredging Boat

NewsAug.09,2025