Jan . 26, 2025 08:39 Back to list

C21 Stainless Steel Shaft Sleeves

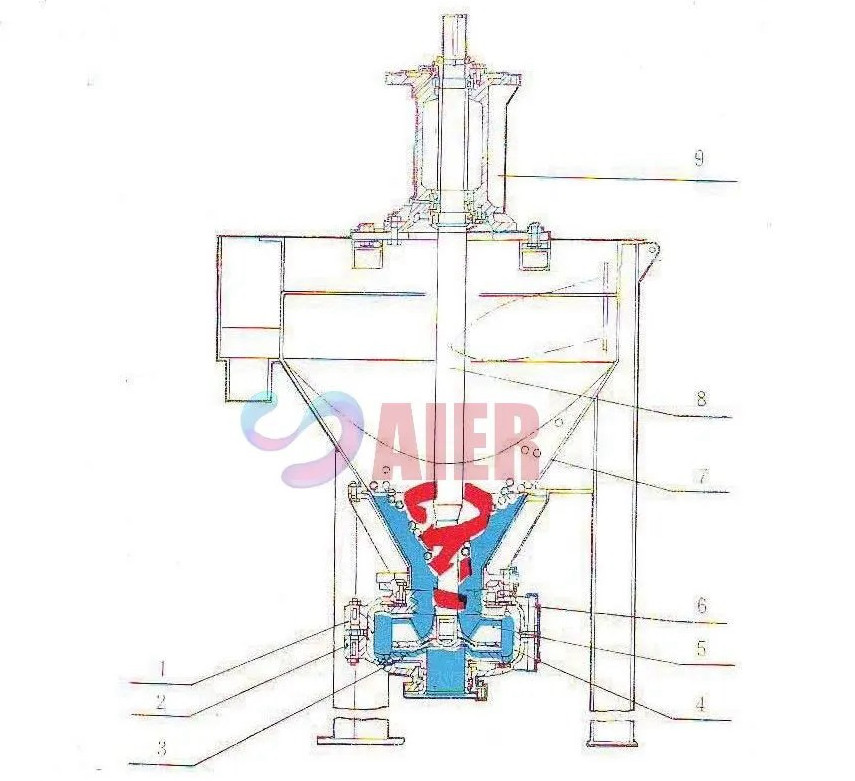

Single stage vertical slurry pumps are integral components in industrial settings relying on the movement and handling of abrasive and corrosive slurries. Their design and engineering sophistication cater to robust needs in industries like mining, mineral processing, and dredging. Professionals who work closely with these pumps often emphasize their operational reliability and efficiency as critical factors in maximizing productivity and minimizing downtime.

Trustworthiness of the manufacturers and suppliers of single stage vertical slurry pumps is another pivotal factor influencing purchase decisions. Industry professionals advise focusing on reputable companies that have a proven track record of delivering durable and efficient pumps. Testimonials from senior operations managers illustrate that partnering with esteemed manufacturers often correlates with access to superior after-sales support, including maintenance services and spare parts availability. The practical experience shared by companies in the mining and dredging sectors further validates the efficacy and reliability of single stage vertical slurry pumps. Companies operating in harsh environments report how these pumps contribute to reducing operational costs, system downtime, and maintenance frequency. Field engineers often cite the minimized footprint and ease of maintenance as key selling points in their operational landscapes. Furthermore, technological advancements have enriched the field of single stage vertical slurry pumps, introducing innovative features such as adjustable flow rates and enhanced sealing mechanisms. These improvements reflect the ongoing commitment of manufacturers to push boundaries, aligning technological development with user needs for enhanced efficacy and robustness. Industry specialists suggest using these features as standard practices to leverage operational adaptability and resilience in unpredictable conditions. In conclusion, as experienced professionals assert, the single stage vertical slurry pump represents an amalgamation of engineering genius and operational dependability. Its ability to convey abrasive slurries efficiently while maintaining structural integrity positions it as a trusted apparatus in demanding industrial operations. When supported by reputable manufacturers and selected based on rigorous evaluation criteria, these pumps serve as a cornerstone asset in enhancing productivity and ensuring seamless industrial functionality. Purchasing decisions substantiated by expert experiences, evaluations, and technological insights continuously validate the premier position of these pumps in the global industrial arena.

Trustworthiness of the manufacturers and suppliers of single stage vertical slurry pumps is another pivotal factor influencing purchase decisions. Industry professionals advise focusing on reputable companies that have a proven track record of delivering durable and efficient pumps. Testimonials from senior operations managers illustrate that partnering with esteemed manufacturers often correlates with access to superior after-sales support, including maintenance services and spare parts availability. The practical experience shared by companies in the mining and dredging sectors further validates the efficacy and reliability of single stage vertical slurry pumps. Companies operating in harsh environments report how these pumps contribute to reducing operational costs, system downtime, and maintenance frequency. Field engineers often cite the minimized footprint and ease of maintenance as key selling points in their operational landscapes. Furthermore, technological advancements have enriched the field of single stage vertical slurry pumps, introducing innovative features such as adjustable flow rates and enhanced sealing mechanisms. These improvements reflect the ongoing commitment of manufacturers to push boundaries, aligning technological development with user needs for enhanced efficacy and robustness. Industry specialists suggest using these features as standard practices to leverage operational adaptability and resilience in unpredictable conditions. In conclusion, as experienced professionals assert, the single stage vertical slurry pump represents an amalgamation of engineering genius and operational dependability. Its ability to convey abrasive slurries efficiently while maintaining structural integrity positions it as a trusted apparatus in demanding industrial operations. When supported by reputable manufacturers and selected based on rigorous evaluation criteria, these pumps serve as a cornerstone asset in enhancing productivity and ensuring seamless industrial functionality. Purchasing decisions substantiated by expert experiences, evaluations, and technological insights continuously validate the premier position of these pumps in the global industrial arena.

Latest news

-

Small Dredger and Marine Pontoon- Aier Machinery Hebei Co., Ltd|Dredging Solutions, Industrial Equipment

NewsJul.30,2025

-

Small Dredger & Marine Pontoon - Aier Machinery Hebei Co., Ltd

NewsJul.30,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd. | Dredging Solutions, Material Handling

NewsJul.30,2025

-

Small Dredger and Marine Pontoon Solutions by Aier Machinery

NewsJul.30,2025

-

Small Dredger and Marine Pontoon Solutions - Aier Machinery | Reliability, Cost-Effectiveness

NewsJul.29,2025

-

Small Dredger - Aier Machinery|Marine Equipment Solutions&Gold Mining

NewsJul.29,2025