Oct . 31, 2024 20:35 Back to list

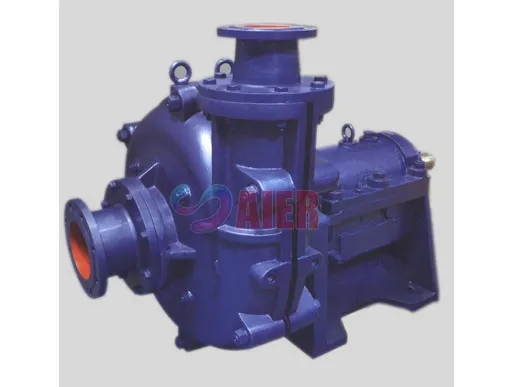

Durable Warman-Style Rubber Lined Slurry Pumps from Leading Manufacturer

High-Quality Warman Rubber Lined Slurry Pump Factory

The slurry pump industry plays a crucial role in various sectors, including mining, construction, and wastewater management. Among the numerous types of slurry pumps available in the market, the Warman rubber lined slurry pump has gained a reputation for its durability and efficiency. In this article, we will explore the features and advantages of high-quality Warman rubber lined slurry pumps, as well as the manufacturing process that ensures their exceptional performance.

Warman pumps are renowned for their robust construction and innovative design. The rubber lining is a pivotal feature, providing excellent resistance to abrasion and corrosion, which is a common issue when handling abrasive slurry materials. This rubber lining not only extends the lifespan of the pump but also reduces maintenance costs, making it a cost-effective solution for businesses dealing with slurry transportation.

One of the key advantages of high-quality Warman rubber lined slurry pumps is their ability to handle a wide range of slurries, including those with high solid content. This versatility makes them suitable for diverse applications such as mineral processing, dredging, and transporting waste materials. The pumps are designed to operate efficiently under varying conditions, ensuring optimal performance even in challenging environments.

high quality warman rubber lined slurry pump factory

When it comes to manufacturing, quality control is of utmost importance. At a reputable Warman rubber lined slurry pump factory, advanced technologies and strict quality assurance protocols are implemented throughout the production process. From the selection of high-grade raw materials to the final assembly of the pumps, every step is meticulously monitored to ensure that the end product meets the highest industry standards.

The factory typically employs a highly skilled workforce, including engineers and technicians with extensive experience in pump design and manufacturing. This expertise allows for continuous improvement and innovation within the factory, leading to the development of pumps that not only meet current market demands but also anticipate future needs.

Furthermore, integrating state-of-the-art technology in the manufacturing process enhances the efficiency and accuracy of production. Computer-aided design (CAD) systems, for instance, are used to create precise pump models, while advanced testing facilities are implemented to rigorously evaluate the performance of each pump before it leaves the factory. This dedication to quality ensures that customers receive products that they can rely on for their specific applications.

In conclusion, high-quality Warman rubber lined slurry pumps are an indispensable asset in various industries where the transportation of abrasive materials is required. With their superior durability, efficiency, and versatility, these pumps offer an effective solution for handling challenging slurry conditions. The manufacturing processes employed by leading Warman rubber lined slurry pump factories not only guarantee the reliability and performance of their products but also contribute to the overall success of their clients. Investing in such pumps means investing in a sustainable and profitable future for any business involved in slurry management.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025