Dec . 20, 2024 16:20 Back to list

china slurry warman pump drawings

Understanding China Slurry Warman Pump Drawings A Comprehensive Overview

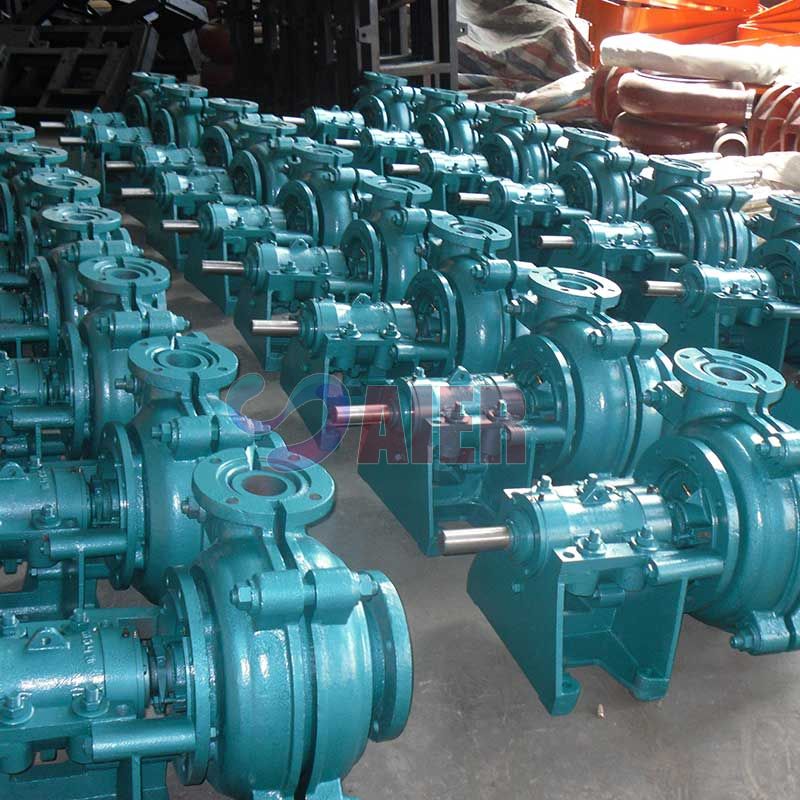

The slurry pump is an essential component in many industrial applications, especially in mining, mineral processing, and heavy-duty industries where the transportation of abrasive and corrosive materials is required. Among the various types of slurry pumps, the Warman pump, designed by Weir Minerals, has become a standard solution globally due to its reliability, efficiency, and robust design. This article will explore the significance of China slurry Warman pump drawings, emphasizing their role in the manufacturing and customization of these vital machines.

Importance of Drawings in Slurry Pump Manufacturing

Drawings play a crucial role in the manufacturing process of machinery, serving as the blueprint from which pumps are produced. For slurry Warman pumps, detailed and precise drawings are necessary for a few reasons

1. Technical Specifications Drawings contain comprehensive specifications that dictate dimensions, materials, and tolerances. They ensure that every component fits and functions correctly within the pump assembly.

2. Quality Control Accurate drawings serve as a benchmark for quality assurance. They allow manufacturers in China and elsewhere to verify that the production meets industry standards and engineering requirements.

3. Customization One of the key advantages of working with drawings is the ability to customize pumps for specific applications. Clients can request modifications, such as material changes to withstand different chemical compositions or adjustments in size to fit particular installations.

4. Communication Drawings facilitate clear communication between manufacturers, engineers, and clients. They provide a visual reference that helps to mitigate misunderstandings that can arise from verbal or written descriptions alone.

Warman Pump Design Features

Warman pumps are distinguished by several innovative design features that optimize their performance in challenging environments

. Key design elements includechina slurry warman pump drawings

- Casing Design Warman pumps usually feature a robust, split casing design that allows for easy maintenance and reduces downtime. The casing is designed to minimize wear and extend the pump's operational life.

- Impeller Configuration The impeller is the heart of the pump, and Warman designs various configurations – including open and closed impellers – to maximize efficiency based on the material being pumped.

- Material Selection In the Chinese manufacturing context, Warman pumps are often constructed using high-chrome alloys or rubber linings to withstand wear and corrosion. The choice of material significantly impacts the pump's longevity and performance.

Manufacturing in China A Global Perspective

China has emerged as a leading hub for the manufacturing of slurry pumps, including Warman designs. The country's advanced manufacturing capabilities, skilled labor force, and cost-effective production methods have facilitated a thriving pump industry.

1. Export Market Chinese manufacturers produce a substantial number of slurry pumps for export, catering to industries worldwide. The international demand for Warman pumps is supported by China’s ability to deliver quality products within competitive timeframes.

2. Innovative Technologies As globalization continues, Chinese manufacturers are investing in advanced technologies, such as CAD (Computer-Aided Design) systems, to produce more efficient and precise pump drawings that align with international standards.

3. Sustainability Practices Increasingly, manufacturers are adopting green practices to bolster their environmental credentials. This involves optimizing designs for energy efficiency and using sustainable materials where possible.

Conclusion

In summary, the China slurry Warman pump drawings are paramount in ensuring the effective design, production, and implementation of these essential industrial machines. The detailed drawings provide the foundation for reliability and performance, catering to diverse global needs. As the industry evolves, continuous improvements in design and manufacturing practices signal a promising future for slurry pumps, making them vital for various sectors that rely on efficient material handling solutions.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025