Feb . 10, 2025 12:37 Back to list

Studs for Cover Plate and Frame Plate

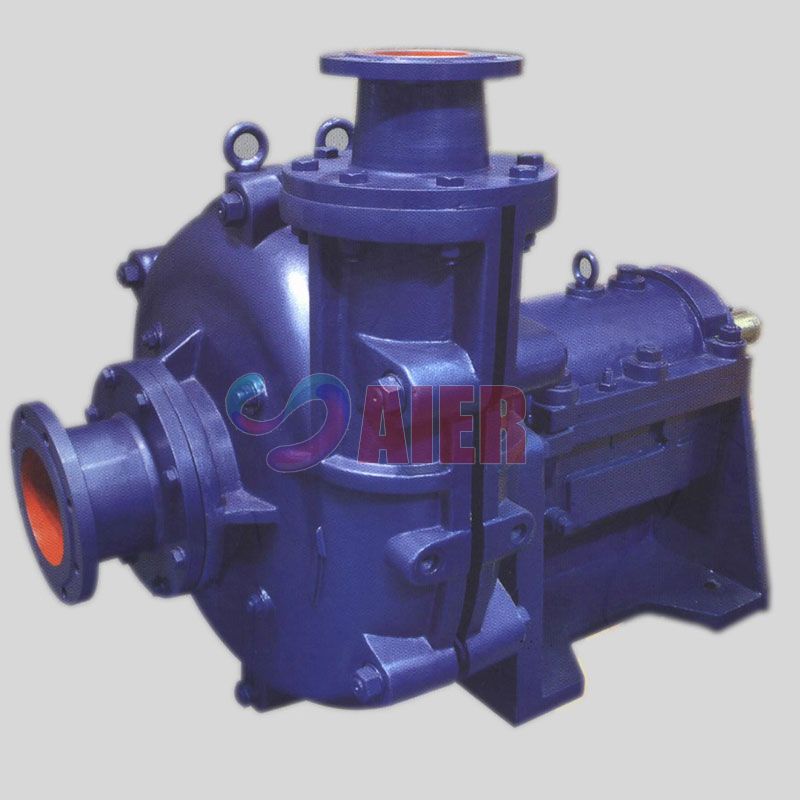

China's sand slurry pump industry has seen significant innovations over the past few years, particularly with the integration of rubber liners. These liners serve a crucial role in enhancing pump performance, durability, and overall operational efficiency. Where metal liners might succumb to abrasion and corrosion, rubber liners offer a resilient alternative that handles the high wear and tear typically associated with sand and slurry handling.

When considering rubber-lined sand slurry pumps, examining real-world case studies and testimonials can guide potential buyers in making informed decisions. Many industries have switched from metal to rubber liners and reported substantial reductions in wear and maintenance needs. This empirical evidence bears weight on the trustworthiness of the promises made by manufacturers, ensuring potential buyers that claims of efficiency are backed by actual data. Chinese manufacturers of sand slurry pumps with rubber liners have honed their expertise over decades, combining traditional craftsmanship with modern technological advancements. This fusion of experience and innovation ensures that they remain at the forefront of the industry, producing pumps that not only meet but often exceed international standards. Their commitment to quality and innovation stands as a testament to their authority in the global marketplace. Trust in these manufacturers is further cemented by their comprehensive post-sale support and warranties. A robust after-sales strategy reassures buyers by providing a safety net if issues arise, a crucial element when investing in heavy-duty industrial equipment. By choosing a manufacturer that offers not just a product but also ongoing support, companies can instill confidence in their operational decisions. In conclusion, for industries contending with abrasive and corrosive slurry, the choice of a sand slurry pump with a rubber liner is a strategic one. It offers not just enhanced performance but also guarantees longevity and reliability. Chinese manufacturers stand as a beacon of expertise and innovation in this field, providing products that consistently deliver exceptional results, grounded in research, experience, and a commitment to quality. This robust combination of factors makes rubber-lined pumps an invaluable asset in maximizing operational efficiency and reducing costs.

When considering rubber-lined sand slurry pumps, examining real-world case studies and testimonials can guide potential buyers in making informed decisions. Many industries have switched from metal to rubber liners and reported substantial reductions in wear and maintenance needs. This empirical evidence bears weight on the trustworthiness of the promises made by manufacturers, ensuring potential buyers that claims of efficiency are backed by actual data. Chinese manufacturers of sand slurry pumps with rubber liners have honed their expertise over decades, combining traditional craftsmanship with modern technological advancements. This fusion of experience and innovation ensures that they remain at the forefront of the industry, producing pumps that not only meet but often exceed international standards. Their commitment to quality and innovation stands as a testament to their authority in the global marketplace. Trust in these manufacturers is further cemented by their comprehensive post-sale support and warranties. A robust after-sales strategy reassures buyers by providing a safety net if issues arise, a crucial element when investing in heavy-duty industrial equipment. By choosing a manufacturer that offers not just a product but also ongoing support, companies can instill confidence in their operational decisions. In conclusion, for industries contending with abrasive and corrosive slurry, the choice of a sand slurry pump with a rubber liner is a strategic one. It offers not just enhanced performance but also guarantees longevity and reliability. Chinese manufacturers stand as a beacon of expertise and innovation in this field, providing products that consistently deliver exceptional results, grounded in research, experience, and a commitment to quality. This robust combination of factors makes rubber-lined pumps an invaluable asset in maximizing operational efficiency and reducing costs.

Latest news

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025