Dec . 23, 2024 15:33 Back to list

Pumps for Lime Slurry Applications in Chinese Manufacturing Industries

The Importance of Pumps for Lime Slurry in Chinese Factories

Lime slurry plays a crucial role in various industrial processes, particularly in the manufacturing, mining, and environmental sectors. The demand for lime slurry has increased significantly in recent years, primarily due to its applications in metal extraction, wastewater treatment, and soil stabilization. In China, the efficient transportation of lime slurry within factories is vital, and this is where specialized pumps become indispensable.

Understanding Lime Slurry

Before delving into the importance of pumps, it is essential to understand what lime slurry is. Lime slurry is a mixture of water and calcium hydroxide, commonly known as hydrated lime. It is produced by mixing quicklime with water, resulting in a versatile solution that is used throughout various industries. Depending on the concentration and particle size, lime slurry's consistency can vary, affecting how it is pumped and transported.

The Role of Pumps in Lime Slurry Transportation

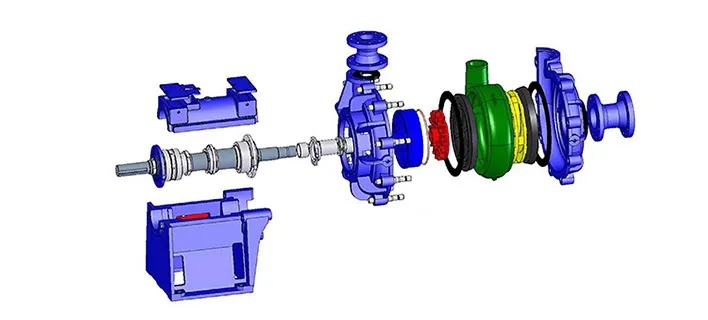

Pumps designed for handling lime slurry are engineered to manage its abrasive and viscous nature. Unlike standard pumps, these specialized devices are built to withstand wear and tear caused by solid particles in the slurry. High efficiency and reliability are critical attributes, especially in Chinese factories where operational downtime can lead to substantial losses.

1. Durability and Material Selection The construction materials of pumps for lime slurry must resist corrosion and erosion. Manufacturers typically use advanced materials such as hardened steel, various alloys, or special coatings to extend the life of the pumps and reduce maintenance costs.

china pump for lime slurry factories

2. Types of Pumps Various types of pumps are suitable for lime slurry applications, including centrifugal pumps, progressive cavity pumps, and diaphragm pumps. Each type has its advantages depending on the specific requirements of the factory. For instance, centrifugal pumps are commonly used for high-flow applications, while diaphragm pumps are favored for their ability to handle thick slurries and solids.

3. Efficiency in Operation Efficient pumping systems improve the overall productivity of a factory. In lime slurry applications, a well-designed pumping system minimizes energy consumption and maximizes flow rates. This efficiency translates to lower operational costs and a smaller carbon footprint, aligning with sustainability goals increasingly prioritized by Chinese manufacturers.

Challenges and Innovations in Pump Technology

Despite the advantages of using specialized pumps for lime slurry, several challenges persist. Pump failures, often due to clogging or wear, can disrupt production and lead to increased maintenance costs. However, advancements in pump technology have led to innovations such as smart monitoring systems that provide real-time data on pump performance. These systems allow factories to detect potential issues before they escalate, thus reducing the risk of unexpected downtime.

Moreover, the integration of automation in pumping processes enhances precision and control. Automated systems can adjust pump operations based on real-time slurry properties, optimizing performance and resource utilization. This technological evolution supports factories in maintaining consistent quality in their lime slurry applications.

Conclusion

As the demand for lime slurry continues to grow within China's industrial landscape, the significance of reliable and efficient pumping systems cannot be overstated. Specialized pumps designed to handle lime slurry contribute to operational efficiency, reduce costs, and minimize environmental impact. With ongoing innovations in pump technology, Chinese factories are poised to enhance their production capabilities while meeting the rising demands of various sectors. Investing in high-quality pumps not only secures the integrity of lime slurry transport but also supports the broader goals of sustainable industrial practices. As industries evolve, those embracing advanced pumping solutions will remain competitive in an ever-changing market.

-

Heavy Duty Vertical Froth Pumps High Efficiency & Durability

NewsMay.24,2025

-

High-Quality Rubber Lined Slurry Pump Spare Parts China Suppliers & Manufacturers

NewsMay.24,2025

-

China Warman Slurry Pump Spares - OEM Parts & Custom Solutions

NewsMay.23,2025

-

China Slurry Pump Group Durable Vertical Sump Pumps & Rubber-Lined Solutions

NewsMay.23,2025

-

High-Quality 6-Inch Submersible Slurry Pumps Trusted Suppliers

NewsMay.23,2025

-

High-Quality Sand Suction Dredge Pump Factories Durable & Efficient

NewsMay.22,2025