дец . 16, 2024 08:14 Back to list

limestone slurry pump factory

Exploring the Limestone Slurry Pump Factory Critical Insights and Innovations

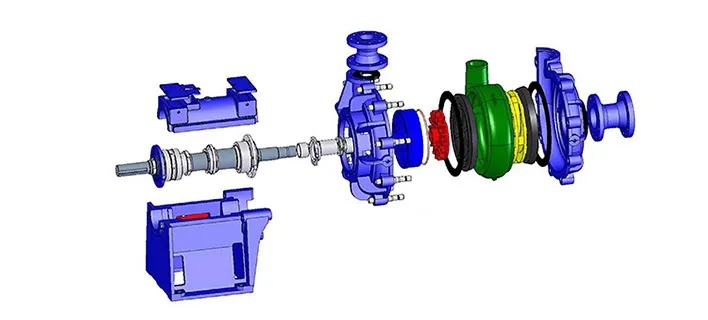

In industrial applications, the transportation of materials is crucial for operational efficiency and productivity. Among various mediums, limestone slurry is a vital component in numerous sectors, including mining, construction, and environmental management. To handle limestone slurry effectively, specialized equipment is essential, which is where limestone slurry pumps come into play. A limestone slurry pump factory plays a pivotal role in the manufacturing of these high-performance pumps, ensuring that industries can reliably move abrasive and corrosive materials.

Understanding Limestone Slurry Pumps

Limestone slurry pumps are designed for the transportation of limestone mixed with water, forming a thick paste that can be challenging to manage with conventional pumps. These pumps are engineered to handle high solids content, making them suitable for various applications where the physical and chemical properties of limestone come into play. Some typical uses include transporting materials for flue gas desulfurization in power plants, dust suppression in mining operations, and the production of cement.

The Role of the Factory in the Industry

The limestone slurry pump factory is not just a manufacturing hub; it is also a center for research and development

. The factory employs skilled engineers and technicians who continuously innovate to improve pump efficiency, durability, and performance. By utilizing advanced materials and cutting-edge technology, these professionals ensure that the pumps can withstand the harsh conditions associated with transporting limestone slurry.The manufacturing process involves several stages, including material selection, design, assembly, and testing. High-quality materials such as high-chrome alloys and rubber linings are often used to enhance the pumps’ resistance to wear and corrosion. The design phase may incorporate computer-aided design (CAD) technologies to optimize performance characteristics and ensure that the pumps meet rigorous industry standards.

Quality Control and Testing

limestone slurry pump factory

Quality control is a fundamental aspect of production in a limestone slurry pump factory. Each pump undergoes a series of tests to ensure it can handle operational conditions effectively. These tests may include hydraulic performance testing, wear testing, and pressure testing. By adhering to stringent quality assurance protocols, factories can ensure that their products meet or exceed customer expectations and industry regulations.

Moreover, the factory often collaborates with clients to customize pumps according to specific requirements. This tailored approach allows industries to access optimal solutions that cater to their unique operational challenges, thereby enhancing productivity and minimizing downtime.

Sustainability and Environmental Considerations

In recent years, there has been an increasing emphasis on sustainable practices in manufacturing. Limestone slurry pump factories are no exception, as they aim to reduce their environmental footprint. This includes implementing energy-efficient production processes, reducing waste, and recycling materials whenever possible. Moreover, pumps designed with lower energy consumption levels contribute to a more sustainable operation for end-users.

In addition, by playing a role in industries focused on environmental remediation, such as water treatment and pollution control, limestone slurry pumps contribute to broader sustainability goals. The ability to effectively transport waste and byproducts ensures that companies can manage their environmental responsibilities more effectively.

Conclusion

The limestone slurry pump factory represents a critical intersection of technology, industry, and sustainability. By producing high-quality, efficient pumps designed to transport abrasive materials, these factories play an essential role in numerous sectors. As industries continue to evolve, the demand for innovative and durable pumping solutions will only grow. With a focus on continuous improvement, quality control, and environmental awareness, limestone slurry pump factories are well-positioned to meet the challenges of the future while contributing to sustainable industrial practices. As such, they are indispensable in the quest for efficiency and effectiveness in material handling within various sectors of the economy.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025