феб . 15, 2025 16:27 Back to list

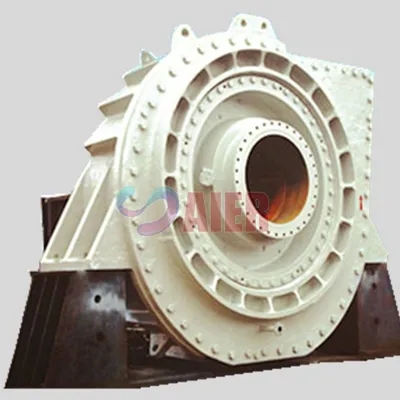

G10083A05 high chrome throatbush

When it comes to high-quality casting slurry pump parts, precision and durability are paramount. For industries reliant on these vital components—such as mining, construction, and wastewater management—the expectation is not just functionality but long-term reliability.

Trustworthiness is paramount when selecting a supplier for casting slurry pump parts. It begins with transparency in processes and communication. Reputable manufacturers provide detailed specifications and material compositions, as well as thorough documentation proving the rigorous testing each component undergoes. This ensures that clients receive exactly what is promised, with full assurance of performance standards. Furthermore, offering warranties or after-sales support underscores a supplier's commitment to quality and customer satisfaction. Investing in high-quality casting slurry pump parts not only enhances efficiency but also plays a crucial role in minimizing operational downtime. Reliability in harsh conditions is not just a bonus but a necessity, preventing costly halts in production. By understanding these aspects, industries can make informed decisions that safeguard their endeavors against potential disruptions, ultimately leading to enhanced productivity and profitability. In conclusion, the commitment to utilizing superior casting slurry pump parts reflects an organization’s dedication to excellence and operational integrity. With a deliberate focus on experience, expertise, authoritative practices, and trustworthiness, companies can ensure their operations are backed by the very best in the industry standards. This not only fortifies their immediate needs but also builds a robust foundation for future growth and innovation.

Trustworthiness is paramount when selecting a supplier for casting slurry pump parts. It begins with transparency in processes and communication. Reputable manufacturers provide detailed specifications and material compositions, as well as thorough documentation proving the rigorous testing each component undergoes. This ensures that clients receive exactly what is promised, with full assurance of performance standards. Furthermore, offering warranties or after-sales support underscores a supplier's commitment to quality and customer satisfaction. Investing in high-quality casting slurry pump parts not only enhances efficiency but also plays a crucial role in minimizing operational downtime. Reliability in harsh conditions is not just a bonus but a necessity, preventing costly halts in production. By understanding these aspects, industries can make informed decisions that safeguard their endeavors against potential disruptions, ultimately leading to enhanced productivity and profitability. In conclusion, the commitment to utilizing superior casting slurry pump parts reflects an organization’s dedication to excellence and operational integrity. With a deliberate focus on experience, expertise, authoritative practices, and trustworthiness, companies can ensure their operations are backed by the very best in the industry standards. This not only fortifies their immediate needs but also builds a robust foundation for future growth and innovation.

Latest news

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025