Nën . 22, 2024 08:28 Back to list

high quality ash slurry submersible pump factory

High-Quality Ash Slurry Submersible Pump Factory A Pillar of Efficiency and Reliability

In today's industrial landscape, the need for efficient and reliable pumping solutions cannot be overstated, particularly in sectors that deal with ash and other abrasive materials. One solution that has gained significant traction is the use of high-quality ash slurry submersible pumps. These pumps play a pivotal role in the safe and effective transportation of ash slurry, which is a byproduct of various industrial processes, including coal combustion and mining operations. As demand grows, so too does the importance of selecting a reputable factory dedicated to producing these specialized pumps.

What are Ash Slurry Submersible Pumps?

Ash slurry submersible pumps are designed to operate submerged in the fluid they are pumping, efficiently handling mixtures of water and solid particles, such as ash. These pumps are engineered to withstand the harsh conditions typical of ash slurry, including high concentrations of abrasive materials and varying densities. Their submersible nature allows them to operate in deep pits or reservoirs, significantly enhancing operational efficiency.

Why Quality Matters

When it comes to industrial pumps, quality is not just a preference; it is a necessity. High-quality pumps offer several advantages, including

1. Longevity Durable materials and robust design ensure that these pumps can withstand the wear caused by abrasive ash components, thereby extending their service life and reducing the need for frequent replacements.

2. Efficiency A well-designed pump maximizes hydraulic efficiency, reducing energy costs and operational downtime. High-quality pumps are engineered to deliver consistent hydraulic performance even in challenging conditions.

3. Reliability In industrial operations, unexpected pump failures can lead to costly downtimes. High-quality pumps are less prone to breakdowns, ensuring continuous operations and minimizing losses.

4. Adaptability Quality manufacturers often provide pumps that can be customized or configured to meet specific operational needs, offering more versatility in various applications.

The Manufacturing Process

high quality ash slurry submersible pump factory

A reputable ash slurry pump factory adheres to stringent manufacturing standards and employs advanced technology to produce these essential tools. The process typically involves several critical stages

1. Material Selection The foundation of a high-quality pump lies in the materials used. Factories utilize corrosion-resistant and wear-resistant materials to manufacture components, ensuring they can withstand harsh operating conditions.

2. Precision Engineering Advanced engineering techniques, including computer-aided design (CAD) and simulation software, are employed to create pump designs that optimize performance and extend service life.

3. Quality Control Rigorous testing is fundamental to any reputable pump manufacturer. Each pump undergoes extensive quality checks, including pressure tests, performance evaluations, and durability assessments.

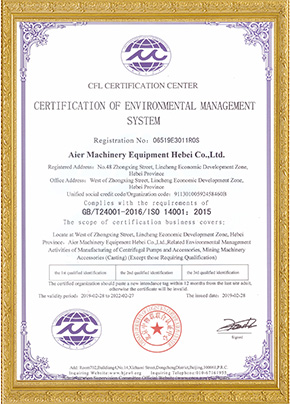

4. Certification Many factories seek certifications from recognized industrial standards organizations, confirming their commitment to quality and safety. These certifications provide clients with the assurance that the products meet international quality benchmarks.

The Role of Innovation

Innovation in pump technology is continually evolving, focusing on improving energy efficiency and reducing environmental impact. Factories that prioritize research and development are more likely to produce cutting-edge pumps, integrating features like smart sensors for real-time monitoring and control systems that optimize performance based on changing conditions.

Conclusion

The landscape of industrial pumping solutions is evolving, with high-quality ash slurry submersible pumps at the forefront of enhancing operational efficiency in various sectors. Choosing a reputable factory that emphasizes quality, innovation, and rigorous manufacturing standards is paramount for companies that rely on these critical tools.

In a world where operational efficiency and sustainability are driving forces, investing in high-quality ash slurry pumps—and sourcing them from a respected factory—can create a significant competitive advantage. The right partnership can lead to improved productivity, reduced operational costs, and, ultimately, a stronger bottom line. As industries continue to grapple with the challenges of waste management and resource efficiency, high-quality ash slurry submersible pumps will remain a cornerstone of effective industrial operations.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025