Sep . 29, 2024 01:19 Back to list

Top Quality Vertical Long Shaft Sump Pumps from Reliable Manufacturer for Various Applications

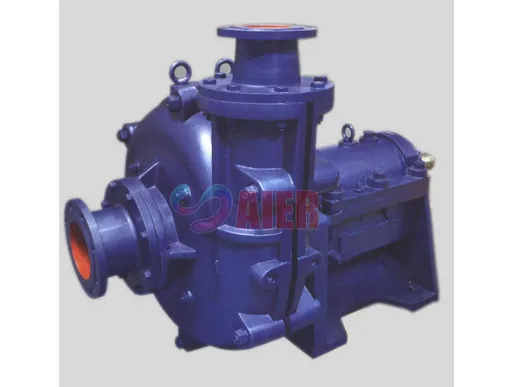

High-Quality Vertical Long Shaft Sump Pump A Comprehensive Overview

In industrial applications, the efficiency of liquid handling often hinges on the choice of equipment, particularly pumps. One significant type of pump used in various sectors is the vertical long shaft sump pump. This specialized equipment is designed to handle various liquids, particularly in environments where submerged solutions are common. This article delves into the characteristics, benefits, and applications of high-quality vertical long shaft sump pumps, with a focus on how top-tier manufacturing can enhance performance.

What is a Vertical Long Shaft Sump Pump?

A vertical long shaft sump pump is a type of pump that is primarily used for handling liquids in sumps, pits, or open water bodies. Its design features a vertical shaft that allows it to be submerged in the liquid it is pumping. The motor and other components are situated above the liquid level, minimizing the risk of damage while maximizing efficiency. These pumps are typically used in mining, wastewater management, pulp and paper industries, and various other applications requiring robust performance.

Key Features and Design Elements

1. Vertical Design The vertical orientation reduces the footprint of the pump, making it particularly suitable for tight spaces where horizontal pumps may not fit. This design also allows for easy removal of the pump for maintenance without needing to drain the sump.

2. Long Shaft The extended shaft allows the impeller to be placed below the liquid surface, enabling efficient pumping of heavy and viscous liquids. The shaft length can be customized according to the depth of the sump or pit.

3. Durable Materials High-quality vertical long shaft sump pumps are constructed from corrosion-resistant materials, such as stainless steel or specialized alloys, to withstand harsh environments. This durability ensures a longer lifespan and reduced maintenance costs.

4. Variable Impeller Sizes Manufacturers often offer pumps with various impeller sizes and designs, allowing for customization based on specific needs. This flexibility enables the pumps to handle differing flow rates and liquid types effectively.

5. Energy Efficiency Advanced motor technology and hydraulic designs contribute to the energy efficiency of high-quality pump models. Lower energy consumption directly correlates with reduced operational costs, which is a significant advantage in large industrial settings.

Benefits of High-Quality Vertical Long Shaft Sump Pumps

1. Reliability and Performance High-quality pumps are designed to deliver consistent performance in demanding environments. With premium components and manufacturing processes, these pumps can operate efficiently for extended periods, even under extreme conditions.

high quality vertical long shaft sump pump factory

2. Easier Maintenance The design of vertical long shaft pumps simplifies maintenance procedures. Many models feature easily accessible components, which can significantly reduce downtime and associated operational costs.

3. Versatility These pumps can handle a wide range of liquids, including those that are abrasive, corrosive, or have high solids content. Their versatility makes them an excellent choice for various industries, ensuring that businesses can adapt to different operational challenges.

4. Cost-Effective Solutions Investing in high-quality vertical long shaft sump pumps represents a cost-effective solution in the long term. While the initial investment may be higher compared to lower-quality pumps, the durability, reliability, and reduced maintenance needs lead to lower lifetime costs.

Applications Across Industries

Vertical long shaft sump pumps find applications in multiple industries

- Wastewater Treatment These pumps are essential in wastewater handling, efficiently removing excess water and sewage.

- Mining and Quarry Operations They help manage water accumulation in mining pits, ensuring safety and operational efficiency.

- Chemical Processing Their ability to handle corrosive and toxic materials makes them suitable for chemical manufacturing facilities.

- Pulp and Paper Industry They efficiently transport slurry and other viscous liquids, contributing to smoother production processes.

Conclusion

In conclusion, high-quality vertical long shaft sump pumps are indispensable in many industrial applications. Their specialized design, durability, and efficiency make them a preferred choice for businesses handling various liquids. By sourcing these pumps from reputable manufacturers, companies can ensure robust performance, reliability, and cost-efficiency in their operations. Investing in a high-quality sump pump is not just a choice; it is a strategic decision that can lead to long-term operational success.

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025

-

High Quality Warman Slurry Pump Drawings Supplier & Factory Reliable Customization

NewsJul.06,2025

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025