Nov . 18, 2024 17:51 Back to list

Centrifugal Slurry Pump Manufacturers and Their Innovative Solutions for Effective Fluid Transfer

Understanding Centrifugal Slurry Pump Factories

Centrifugal slurry pumps are essential in various industrial applications, especially in mining, mineral processing, and wastewater treatment. These pumps are designed to handle abrasive and viscous fluids, making them critical components in industries that deal with slurry transport. The factories that manufacture these pumps play a vital role in ensuring that high-quality, durable products reach the market.

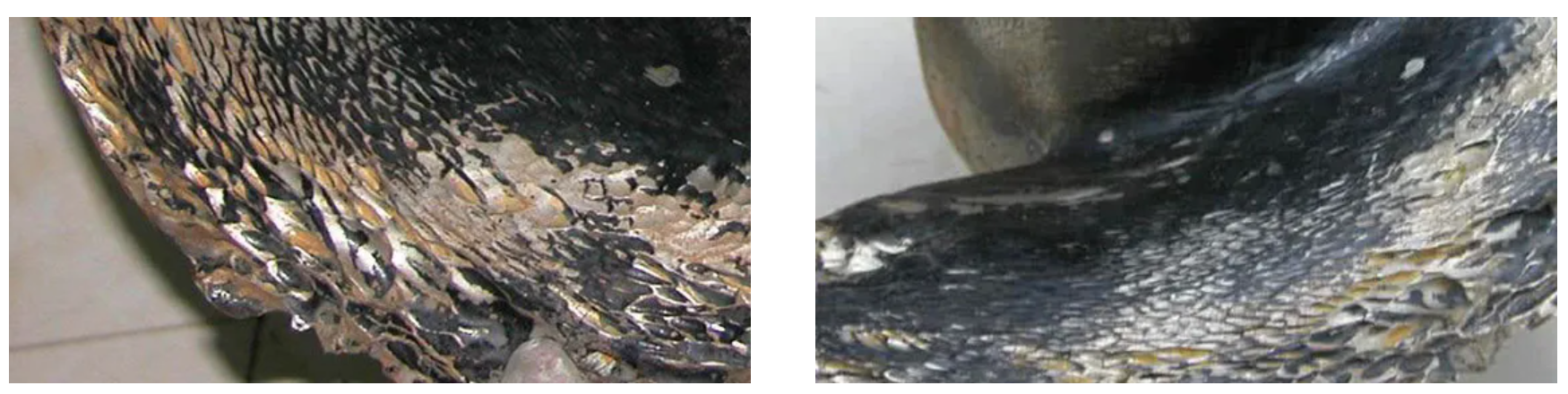

In a centrifugal slurry pump factory, the production process begins with the selection of materials. The pumps are typically made from high-chromium alloys or rubberized components to withstand the wear and tear caused by abrasive materials. The manufacturing process involves precision machining, assembly, and rigorous testing to ensure that each pump meets the necessary performance specifications and quality standards.

One of the key considerations in designing a centrifugal slurry pump is its hydraulic efficiency. Engineers utilize computer-aided design (CAD) software to create models that optimize the pump's geometry. By enhancing the impeller and casing designs, factories can produce pumps that maximize flow rates while minimizing energy consumption. Moreover, the innovation in pump design helps in reducing maintenance frequency and extending the lifespan of the pumps, which is crucial for industries operating under continuous production schedules.

centrifugal slurry pump factories

Quality assurance is another critical aspect of centrifugal slurry pump factories

. Every stage of the manufacturing process, from material selection to final assembly, is monitored to ensure compliance with industry standards. Factories often employ quality control inspectors who perform tests such as pressure testing, cavitation testing, and performance benchmarking to guarantee the reliability and efficiency of the pumps.Furthermore, many centrifugal slurry pump manufacturers are now embracing sustainable practices in their production processes. This includes recycling materials, reducing waste, and implementing energy-efficient manufacturing techniques. By focusing on sustainability, these factories not only contribute to environmental conservation but also appeal to a growing market of eco-conscious consumers and businesses.

In conclusion, centrifugal slurry pump factories are pivotal in producing robust and efficient pumps that cater to various industrial needs. With advanced engineering designs, stringent quality control measures, and a commitment to sustainability, these factories ensure that the pumps meet the demanding requirements of users across different sectors. As industries continue to evolve, the role of these factories will be crucial in supporting innovation and enhancing operational efficiencies.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025