Nov . 10, 2024 06:28 Back to list

Vertical Slurry Sump Pump Manufacturing and Design Solutions for Efficient Liquid Handling

Understanding Vertical Slurry Sump Pumps A Key Component in Industrial Operations

Vertical slurry sump pumps are integral to many industrial operations, particularly in sectors such as mining, wastewater treatment, and chemical processing. These pumps are designed to handle abrasive and corrosive slurry materials, which consist of a mixture of liquid and solid particles. Their robust construction and efficiency make them suitable for a variety of applications where conventional pumps might fail.

What are Vertical Slurry Sump Pumps?

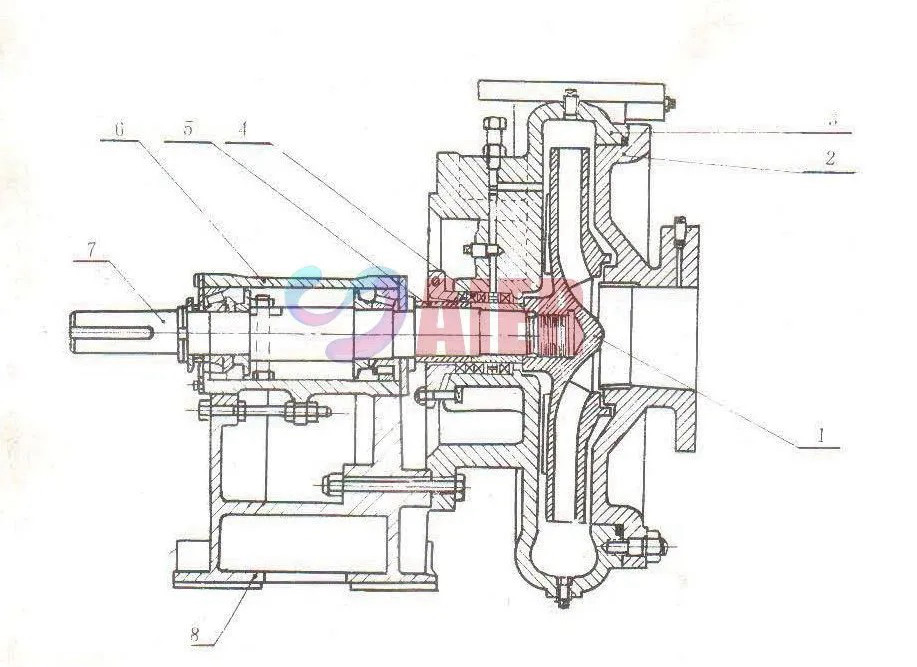

A vertical slurry sump pump is characterized by its vertical orientation and its submersible design, allowing it to be submerged in the slurry pit or sump from which it draws material. Unlike standard centrifugal pumps, these pumps are engineered to pump thick, viscous mixtures that contain solid particles. The vertical design aids in the efficient handling of slurries, requiring less floor space and reducing the risk of cavitation, which can be detrimental to pump performance.

Key Features and Benefits

1. Durability Vertical slurry sump pumps are constructed from heavy-duty materials like high-chrome alloy, which ensures high resistance to wear and corrosion. This durability is essential for industrial applications where the presence of abrasive solids in the slurry can lead to rapid wear of standard pump components.

2. Self-Priming These pumps often feature a self-priming mechanism, allowing them to operate even when the slurry levels are low. This capability minimizes downtime and maintenance work, which is crucial for maintaining operational efficiency in industrial settings.

3. Versatile Applications Vertical slurry sump pumps are versatile and can be used in various applications, including mining operations for ore transport, in paper mills for pulp handling, and in wastewater treatment for transferring sludge. Their adaptability to different environments makes them a preferred choice among plant operators.

vertical slurry sump pump factory

4. Energy Efficiency Many modern vertical slurry sump pumps are designed to be energy-efficient. By optimizing the hydraulic design, manufacturers can produce pumps that require less energy to achieve the same performance levels, consequently reducing operational costs.

5. Low Maintenance The design of these pumps often includes features that minimize wear and tear, reducing the need for frequent maintenance. The ability to operate in harsh environments lends itself to fewer maintenance interruptions, thereby promoting higher productivity levels.

Manufacturing Process of Vertical Slurry Sump Pumps

The manufacturing process of vertical slurry sump pumps involves several critical phases. First, material selection is key; high-quality alloys are chosen to withstand the corrosive nature of the slurries they will handle. Next, precision engineering is essential to create components that can maintain high performance under challenging conditions.

After manufacturing, quality testing is rigorously conducted to ensure that every pump meets industry standards for efficiency and durability. This includes tests for flow rate, pressure, and the pump’s ability to handle solid particles without clogging.

Conclusion

Vertical slurry sump pumps stand as a testament to the advancements in engineering and manufacturing technologies. By providing effective solutions for transferring abrasive and viscous materials, they play a vital role in the efficiency and productivity of various industrial processes. As industries continue to evolve and demand more robust and efficient pumping solutions, the importance of specialized equipment like vertical slurry sump pumps will only increase. Companies that invest in these pumps are likely to experience enhanced operational efficacy, reduced costs, and improved overall performance, making them a savvy choice in the world of industrial machinery.

In conclusion, understanding the significance and functionality of vertical slurry sump pumps is essential for decision-makers in industries reliant on the efficient handling of slurries. These pumps not only streamline operational processes but also contribute to the sustainability and economic viability of industrial operations.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025