Feb . 06, 2025 00:52 Back to list

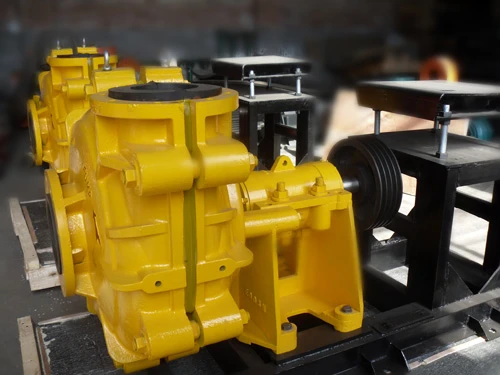

slurry pump exchangable with warman pumps

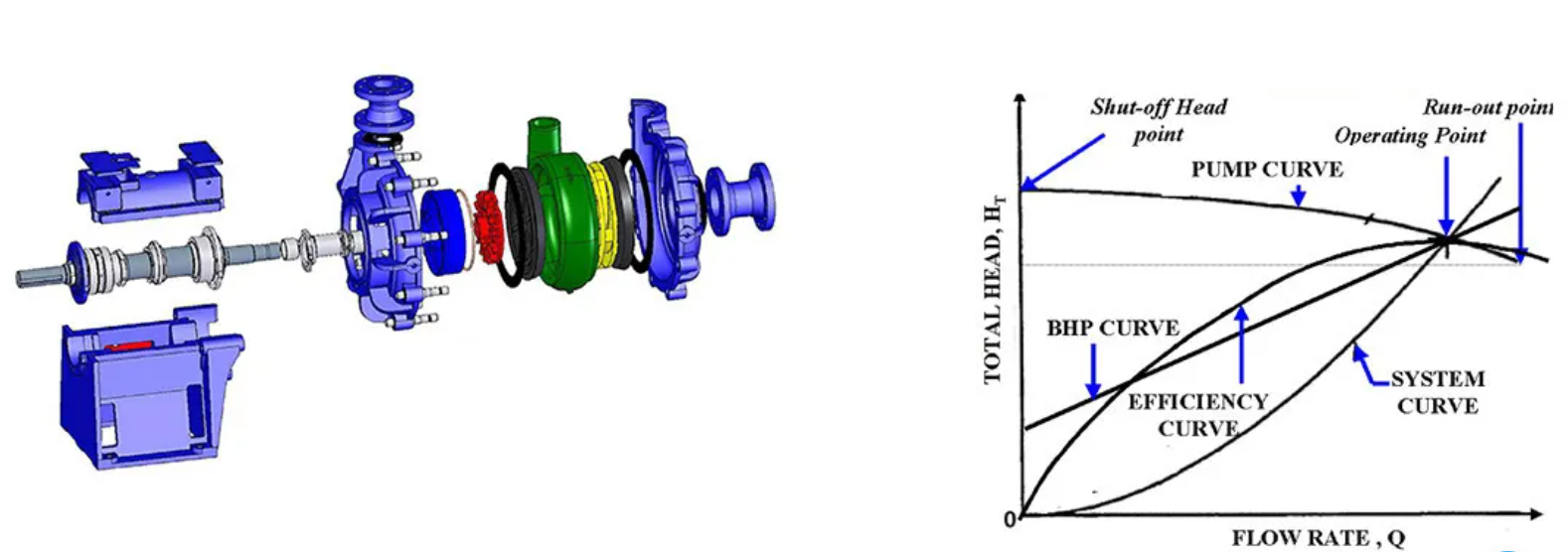

Choosing the right slurry pump for industrial applications can be a daunting task given the multitude of options available in the market. One frequently asked question is whether certain slurry pumps are interchangeable with those from the renowned Warman brand. The answer lies in understanding the intricate design, performance capabilities, and specific use cases of these pumps.

Authoritative Insights for Decision-Makers For those tasked with integrating a replacement pump, industry experts often emphasize the importance of detailed engineering assessments and consultations. Trusted manufacturers that provide Warman-equivalent pumps usually supply detailed installation guides and perform on-site analyses to ensure compatibility. Purchasing from reputable suppliers who can provide performance warranties and after-sales support ensures that decision-makers are backed by technical assurances. In many cases, direct warman-compatible pumps offer cost advantages without sacrificing essential performance attributes. Companies with expertise in slurry pump engineering assist clients in aligning their pump investments with operational longevity and cost efficiency. This authoritative role not only saves businesses from unforeseen downtime but also optimizes their operations over the lifespan of the equipment. Trustworthy Practices in Pump Replacement Replacing a slurry pump is an investment, and businesses aim to maximize returns. Therefore, partnering with manufacturers and suppliers who have a proven track record and reputation in the industry is indispensable. Testimonials and case studies often provide real-world evidence of pump capability, while certifications and compliance with international standards further establish the reliability and trustworthiness of a product. Additionally, organizations should explore trial installations or phased integration to test the performance under actual operating conditions. This pragmatic approach ensures that investment decisions are informed by tangible results and peer-reviewed data, thereby reinforcing the trust in the practical outcomes promised by alternative pumps. In conclusion, while slurry pumps can be exchanged with Warman pumps in certain contexts, the process demands a thorough, professional evaluation of technical and operational criteria. The right choice not only hinges on immediate cost savings but also the long-term performance and reliability that these industrial workhorses can deliver. Whether seeking seamless interchangeability or superior customization, businesses can optimize their slurry handling solutions by adhering to expert, authoritative, and trustworthy methodologies.

Authoritative Insights for Decision-Makers For those tasked with integrating a replacement pump, industry experts often emphasize the importance of detailed engineering assessments and consultations. Trusted manufacturers that provide Warman-equivalent pumps usually supply detailed installation guides and perform on-site analyses to ensure compatibility. Purchasing from reputable suppliers who can provide performance warranties and after-sales support ensures that decision-makers are backed by technical assurances. In many cases, direct warman-compatible pumps offer cost advantages without sacrificing essential performance attributes. Companies with expertise in slurry pump engineering assist clients in aligning their pump investments with operational longevity and cost efficiency. This authoritative role not only saves businesses from unforeseen downtime but also optimizes their operations over the lifespan of the equipment. Trustworthy Practices in Pump Replacement Replacing a slurry pump is an investment, and businesses aim to maximize returns. Therefore, partnering with manufacturers and suppliers who have a proven track record and reputation in the industry is indispensable. Testimonials and case studies often provide real-world evidence of pump capability, while certifications and compliance with international standards further establish the reliability and trustworthiness of a product. Additionally, organizations should explore trial installations or phased integration to test the performance under actual operating conditions. This pragmatic approach ensures that investment decisions are informed by tangible results and peer-reviewed data, thereby reinforcing the trust in the practical outcomes promised by alternative pumps. In conclusion, while slurry pumps can be exchanged with Warman pumps in certain contexts, the process demands a thorough, professional evaluation of technical and operational criteria. The right choice not only hinges on immediate cost savings but also the long-term performance and reliability that these industrial workhorses can deliver. Whether seeking seamless interchangeability or superior customization, businesses can optimize their slurry handling solutions by adhering to expert, authoritative, and trustworthy methodologies.

Latest news

-

Top Submersible Well Pump Manufacturer – Reliable & Efficient Solutions

NewsJul.28,2025

-

Wholesale Slurry Pump Rubber Impeller for Mining & Industry

NewsJul.27,2025

-

Reliable Submersible Well Pump Manufacturer – Quality & Durability

NewsJul.26,2025

-

Submersible Pump Shaft Manufacturer - High Quality Vertical and Ceramic Slurry Pumps

NewsJul.25,2025

-

Top Submersible Well Pump Manufacturer - Reliable & Durable Solutions

NewsJul.24,2025

-

Leading Submersible Well Pump Manufacturer – Reliable & Durable Pumps

NewsJul.23,2025