Jan . 28, 2025 06:22 Back to list

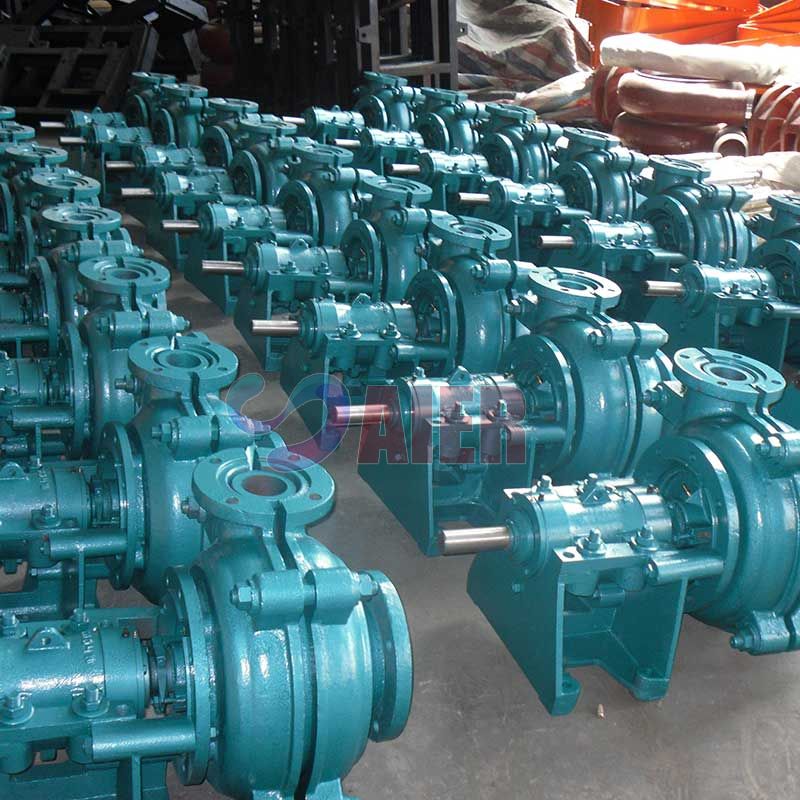

BCT Ceramic Slurry Pumps

The open rubber slurry pump impeller is an integral component in various industries, offering unique advantages and features that cater to specific operational needs. As a cornerstone in material handling, this impeller type is specifically designed to optimize performance in slurry pumps, which are often used in mining, dredging, and other heavy-duty applications. Understanding its functionality and benefits is crucial for businesses looking to enhance efficiency and durability in their operations.

When it comes to trustworthiness and authoritativeness in the market, companies should prioritize manufacturers and distributors with a proven track record. Established manufacturers provide comprehensive support and guidance, from the selection process through to after-sales service, which is vital for maintaining optimal pump performance. Certification and compliance with industry standards further affirm a product’s reliability and the manufacturer’s commitment to excellence. Safety and environmental considerations also come into play when utilizing open rubber slurry pump impellers. The choice of materials not only impacts operational efficiency but also environmental sustainability. Rubber is often favored due to its lower environmental footprint compared to heavier, non-renewable metal components. Additionally, using impellers designed to reduce energy consumption can further align operations with environmental goals, promoting sustainable industry practices. In conclusion, open rubber slurry pump impellers represent a pivotal advancement in material handling technology. Their unique benefits, like improved wear resistance, energy efficiency, and the ability to handle large, abrasive solids, make them indispensable in demanding industrial environments. By leveraging professional expertise and focusing on reputable manufacturers, companies can ensure that their slurry pumping systems remain efficient, reliable, and sustainable, thereby enhancing overall productivity and profitability. As industries continue to evolve, the emphasis on durable and efficient technologies like the open rubber slurry pump impeller will undoubtedly increase, underscoring their significance in the modern industrial landscape.

When it comes to trustworthiness and authoritativeness in the market, companies should prioritize manufacturers and distributors with a proven track record. Established manufacturers provide comprehensive support and guidance, from the selection process through to after-sales service, which is vital for maintaining optimal pump performance. Certification and compliance with industry standards further affirm a product’s reliability and the manufacturer’s commitment to excellence. Safety and environmental considerations also come into play when utilizing open rubber slurry pump impellers. The choice of materials not only impacts operational efficiency but also environmental sustainability. Rubber is often favored due to its lower environmental footprint compared to heavier, non-renewable metal components. Additionally, using impellers designed to reduce energy consumption can further align operations with environmental goals, promoting sustainable industry practices. In conclusion, open rubber slurry pump impellers represent a pivotal advancement in material handling technology. Their unique benefits, like improved wear resistance, energy efficiency, and the ability to handle large, abrasive solids, make them indispensable in demanding industrial environments. By leveraging professional expertise and focusing on reputable manufacturers, companies can ensure that their slurry pumping systems remain efficient, reliable, and sustainable, thereby enhancing overall productivity and profitability. As industries continue to evolve, the emphasis on durable and efficient technologies like the open rubber slurry pump impeller will undoubtedly increase, underscoring their significance in the modern industrial landscape.

Latest news

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025

-

High Quality Warman Slurry Pump Drawings Supplier & Factory Reliable Customization

NewsJul.06,2025

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025