Oct . 13, 2024 01:47 Back to list

high quality centrifugal slurry pump spares manufacturer

High-Quality Centrifugal Slurry Pump Spares A Comprehensive Guide

In the demanding world of industrial applications, the efficiency and reliability of equipment play a critical role in maintaining operational excellence. One such crucial piece of equipment is the centrifugal slurry pump, widely utilized across various industries, including mining, construction, and wastewater treatment. As these pumps operate in challenging environments, the importance of high-quality spare parts cannot be overstated. This article delves into the realm of centrifugal slurry pump spares, emphasizing the significance of quality and providing insights into choosing the right manufacturer.

Understanding Centrifugal Slurry Pumps

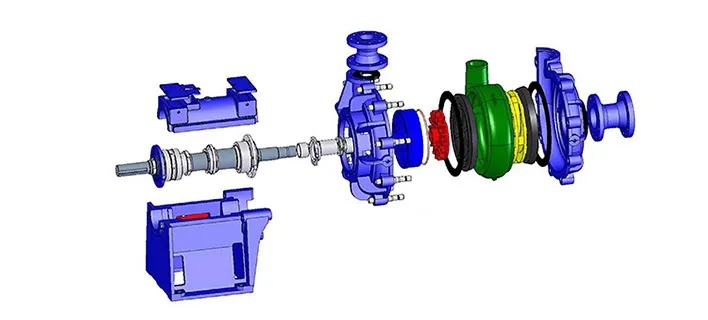

Centrifugal slurry pumps are designed to transport abrasive and viscous liquids—known as slurries—containing solid particles. These pumps typically feature a robust construction, made to withstand wear and tear from constant use in harsh conditions. The efficiency of these pumps relies heavily on their components, including impellers, liners, mechanical seals, and bearings. Therefore, the quality of spare parts directly impacts the overall performance, longevity, and cost-effectiveness of the pumps.

Importance of High-Quality Spare Parts

Investing in high-quality spare parts for centrifugal slurry pumps is crucial for several reasons

1. Performance Optimization High-quality components ensure that pumps operate at their optimal efficiency, reducing the risk of downtime and the associated costs. Quality spares can maintain or even enhance the performance of the pumps under challenging operating conditions.

2. Longevity and Durability Premium spare parts are often made from superior materials that can withstand abrasion, corrosion, and other damaging factors. This durability not only extends the lifespan of the pumps but also minimizes the frequency of replacements, leading to significant cost savings in the long run.

3. Safety and Compliance In many industries, maintaining safety standards and regulatory compliance is critical. Using genuine, high-quality spare parts helps ensure that pumps operate within safety parameters, reducing the risk of failures that could lead to hazardous situations.

4. Reduced Maintenance Costs Quality spares often require less frequent replacement and repair. This not only lowers maintenance costs but also helps in minimizing operational disruptions, allowing for a more streamlined workflow.

high quality centrifugal slurry pump spares manufacturer

Choosing the Right Manufacturer

When it comes to selecting a manufacturer for centrifugal slurry pump spares, several factors should be considered

1. Reputation and Experience Look for manufacturers with a solid track record in the industry. A company that has been in the business for a significant period is likely to have a better understanding of quality requirements and customer needs.

2. Material Quality Inquire about the materials used in manufacturing the spares. High-quality materials, such as wear-resistant alloys, are crucial for ensuring long-lasting performance in abrasive environments.

3. Certification and Standards Ensure that the manufacturer adheres to industry standards and has relevant certifications. This not only reflects the quality of their products but also their commitment to maintaining high production standards.

4. Customer Support and Service A reliable manufacturer should provide excellent customer support, including guidance on installation, maintenance, and troubleshooting. Strong after-sales support is vital for addressing any issues that may arise.

5. Customization Options Some manufacturers offer customization services tailored to specific application needs. Choosing a manufacturer that can adapt spares to meet unique operational requirements can significantly enhance the performance of your pumps.

6. Warranty and Return Policy A good warranty policy indicates the manufacturer’s confidence in their products. Understanding the terms of warranty and the return policy can provide additional assurance when making a purchase.

Conclusion

High-quality centrifugal slurry pump spares are an essential component of effective and efficient industrial operations. By investing in superior spare parts from reputable manufacturers, businesses can enhance the performance and durability of their pumps, leading to improved productivity and lower operational costs. Organizations must conduct thorough research and consider various factors when choosing a manufacturer to ensure they receive the best quality products that meet their specific needs. In a competitive industrial landscape, the decision to prioritize quality in pump components can make all the difference in achieving sustained success.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025