Nov . 04, 2024 22:54 Back to list

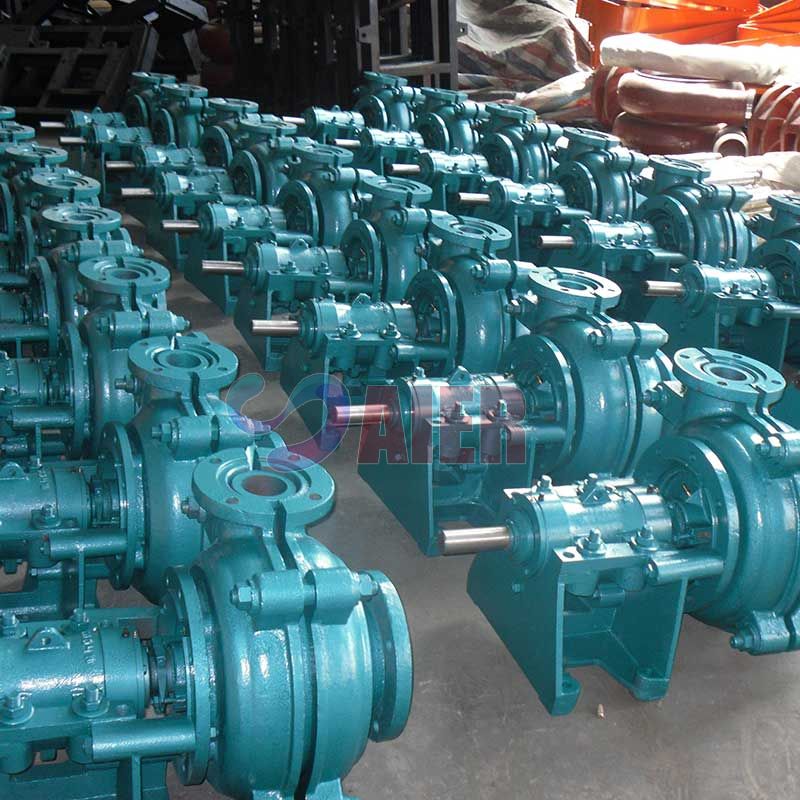

china horizontal froth pump

Understanding China’s Horizontal Froth Pump

In recent years, the mining and mineral processing industries have seen a significant evolution in the technology and equipment used for transporting mixtures of solids and liquids. One of the noteworthy advancements is the development of the horizontal froth pump, particularly in China, where industrial innovation is on the rise. This type of pump is especially designed to handle frothy slurries, which are commonly encountered in flotation processes used in the mining industry for mineral separation.

The Need for Horizontal Froth Pumps

Froth flotation is a widely used separation technique that involves the generation of froth to separate valuable minerals from gangue. During this process, slurry is created, and the formation of bubbles assists in carrying the concentrated material to the surface. However, transporting these frothy slurries can be challenging because the froth can easily collapse or de-aerate, leading to decreased efficiency and increased wear on equipment. The horizontal froth pump was developed to address these challenges, providing a more efficient means of transferring froth mixtures while minimizing energy consumption and reducing maintenance needs.

Design and Functionality

The horizontal froth pump is specifically engineered with a unique design that helps to maintain the froth’s integrity during transport. Unlike traditional vertical pumps, which can lead to agitation and collapse of froth, horizontal pumps facilitate a smoother flow. The pump’s impeller is designed to handle the abrasiveness and thick viscosity of frothy slurries without causing significant damage.

Key features of horizontal froth pumps include

1. Spiral Overflow Design This design prevents the settling of solids and allows for continuous transport of froth without turbulence. It also allows for easier access to the pump for maintenance purposes.

2. Wear-resistant Materials Horizontal froth pumps are typically constructed with high wear-resistant materials, which extend their lifespan and reliability. This is crucial in minimizing downtime in operations.

china horizontal froth pump

3. Adjustable Impeller Speed Many modern froth pumps allow users to adjust the impeller speed, helping operators to optimize the flow rate and energy consumption based on specific operational requirements.

4. Self-Priming Capability This feature is essential for handling the froth without needing external priming devices, thus simplifying the setup and operation of the pump.

Applications in Various Industries

The applications for horizontal froth pumps extend beyond just mining. They are also utilized in various industries where frothy mixtures are common, such as in wastewater treatment, chemical processing, and in the pulp and paper industry. In wastewater treatment plants, for instance, froth pumps are invaluable for transporting sludge and foam, thereby facilitating more efficient waste management practices.

Additionally, in the coal and mineral processing industries, these pumps play a role in efficiently transferring various slurries, enabling better separation and recovery rates of target materials. By ensuring that the froth remains intact during transportation, these pumps contribute significantly to overall resource recovery efficiency and reduce operational costs.

The Future of Horizontal Froth Pumps in China

China’s industrial landscape is rapidly evolving, with a strong push toward increased efficiency, sustainability, and technological advancement. The development and adoption of horizontal froth pumps reflect this trend. As more companies recognize the benefits of this technology, it is likely that these pumps will become standard equipment in various sectors.

Furthermore, with ongoing investments in research and development, we can expect to see continued enhancements in pump design, performance, and material technology. These advancements will further boost the effectiveness of horizontal froth pumps, contributing to higher productivity and sustainability in industrial processes.

In conclusion, the horizontal froth pump represents a significant technological advancement in the management of frothy slurries, particularly in the mining and mineral processing industries. With its robust design and efficient operation, it is poised to leave a lasting impact on how these industries operate, particularly in regions like China where such innovations are increasingly crucial in maintaining competitive advantages. As the demand for effective mineral processing continues to grow, so too will the prominence and evolution of horizontal froth pumps in the global market.

-

China Portable Slurry Pump Manufacturer - Durable & Efficient Submersible Design

NewsMay.29,2025

-

High-Quality Submersible Slurry Pumps Reliable Manufacturer & Supplier

NewsMay.29,2025

-

High-Quality Sand Dredge Pump 8 Durable Manufacturer & Supplier

NewsMay.29,2025

-

Electric Submersible Slurry Pump - Durable & Efficient China Suppliers

NewsMay.29,2025

-

Submersible Slurry Pump with Agitator Durable China Suppliers & Manufacturers

NewsMay.29,2025

-

Vertical Sump Pump Rubber Lined - Durable Corrosion-Resistant Design China Manufacturers

NewsMay.29,2025