Sep . 04, 2024 13:01 Back to list

china slurry pump seals manufacturer

China Slurry Pump Seals Manufacturer Ensuring Efficiency and Durability

In the world of industrial pumping, slurry pumps play a critical role, particularly in the mining, construction, and wastewater sectors. As these pumps transport abrasive and corrosive materials, the efficiency and reliability of their seals are paramount. This is where specialized manufacturers in China provide invaluable expertise and innovation.

Understanding Slurry Pumps and Their Seals

Slurry pumps are specifically designed to move a mixture of liquid and solid particles, often under challenging conditions. These pumps are subjected to intense wear and tear due to the abrasive nature of the materials they handle. Consequently, the seals used in slurry pumps must withstand severe operational conditions, including high pressures and temperatures, all while preventing leaks that could lead to costly downtime and environmental hazards.

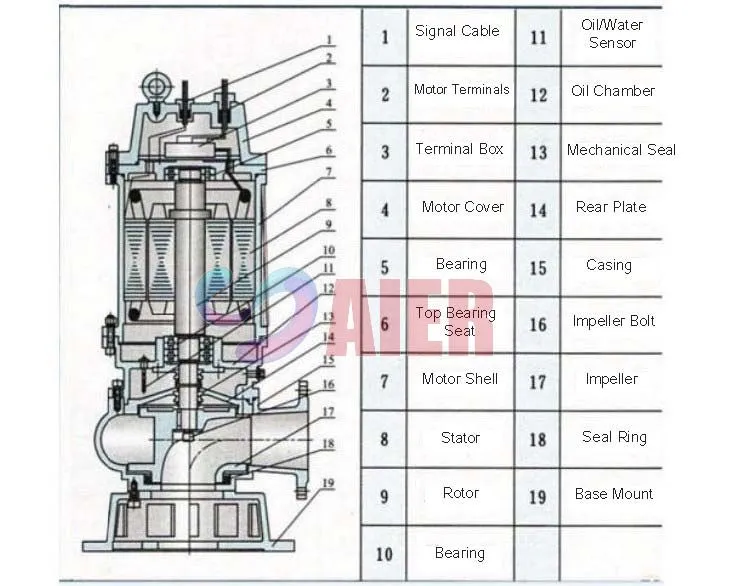

The main types of seals used in slurry pumps include mechanical seals, gasket seals, and lip seals. Each type has its unique advantages and applications, depending on the specific requirements of the pumping system. A reliable seal extends the life of the pump, enhances its efficiency, and reduces the frequency of maintenance.

China's Role in the Slurry Pump Seal Market

China has emerged as a global leader in the manufacturing of slurry pump seals, owing to its advanced production technologies and skilled workforce. Chinese manufacturers utilize cutting-edge materials, such as high-grade rubber, ceramics, and advanced polymers, to design seals that can withstand the rigors of slurry pumping. Additionally, the ability to conduct extensive research and development ensures that these products keep pace with the constantly evolving industrial standards.

china slurry pump seals manufacturer

One major advantage of sourcing slurry pump seals from China is cost competitiveness. Manufacturers in China are able to produce high-quality seals at a lower cost compared to their counterparts in other regions. This cost-effectiveness is particularly beneficial for companies operating on tight margins, allowing them to invest in other critical areas of their operations.

Quality Assurance and Certifications

Renowned Chinese slurry pump seal manufacturers adhere to stringent quality control processes and often hold international certifications such as ISO 9001. These certifications guarantee that the seals meet global quality standards, providing clients with confidence in their durability and performance. Moreover, many manufacturers offer warranties and after-sales support, ensuring that clients receive assistance in case of product failures or operational issues.

Innovations in Seal Technology

The industry is continuously evolving, and leading Chinese manufacturers are at the forefront of innovation. Recent advancements include the development of self-lubricating seals and seals with enhanced resistance to chemical corrosion. These innovations not only improve the lifespan of the seals but also optimize the performance of slurry pumps, leading to significant operational efficiencies.

Conclusion

In summary, the importance of high-quality slurry pump seals cannot be overstated, particularly in industries dealing with abrasive and corrosive materials. China’s position as a premier manufacturer of these seals is driven by cost-effective production, rigorous quality standards, and continuous innovation. Companies looking to enhance their slurry pumping operations would do well to consider partnerships with reputable Chinese manufacturers, ensuring they benefit from products that maximize efficiency and minimize downtime. As industries continue to grow and evolve, the demand for reliable and durable slurry pump seals will only increase, making Chinese manufacturers crucial players in this vital sector of the economy.

-

China Portable Slurry Pump Manufacturer - Durable & Efficient Submersible Design

NewsMay.29,2025

-

High-Quality Submersible Slurry Pumps Reliable Manufacturer & Supplier

NewsMay.29,2025

-

High-Quality Sand Dredge Pump 8 Durable Manufacturer & Supplier

NewsMay.29,2025

-

Electric Submersible Slurry Pump - Durable & Efficient China Suppliers

NewsMay.29,2025

-

Submersible Slurry Pump with Agitator Durable China Suppliers & Manufacturers

NewsMay.29,2025

-

Vertical Sump Pump Rubber Lined - Durable Corrosion-Resistant Design China Manufacturers

NewsMay.29,2025