dec . 10, 2024 12:15 Back to list

china centrifugal slurry pump parts factories

Understanding China’s Centrifugal Slurry Pump Parts Factories

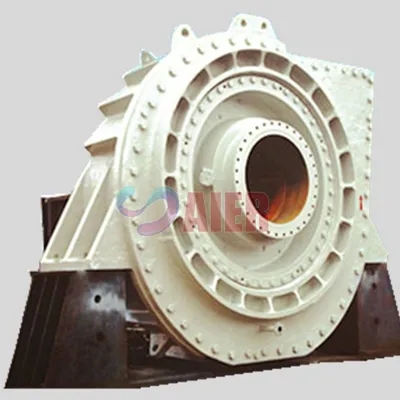

Centrifugal slurry pumps play a crucial role in various industries, particularly in mining, metallurgy, and construction. These pumps are designed to handle abrasive and viscous materials, including slurries that contain solid particles. Given their importance, it's essential to explore the factories in China that specialize in the production of these pumps and their components.

The Role of Slurry Pumps

Centrifugal slurry pumps are used to transport slurries—mixtures of liquids and solids—over long distances and at high pressures. Their design enables them to handle the demanding requirements of pumping materials that are often corrosive, abrasive, or of variable consistency. Applications include mining operations, where large volumes of mineral slurries need to be managed, as well as wastewater treatment facilities and chemical processing plants.

Manufacturing Landscape in China

China has established itself as a global leader in the manufacturing of industrial equipment, including centrifugal slurry pumps and their individual parts. The advantages of manufacturing in China, including cost-effectiveness, scalability, and rapid production capabilities, have attracted many companies looking to source high-quality pump components.

1. Production Capabilities

Chinese factories are equipped with advanced machinery and state-of-the-art technology, enabling them to produce a wide range of components, such as pump casings, impellers, and wear plates. These components are often made from high chromium alloy or rubber materials to enhance their durability against abrasive slurries. The ability to customize products according to specific client requirements is another significant advantage that Chinese manufacturers offer.

Quality control is a significant aspect of the manufacturing process in these factories. Most adhere to international standards, such as ISO 9001, ensuring that each part produced is rigorously tested for strength, durability, and performance. Manufacturers often utilize advanced testing techniques, including hydrostatic tests and performance testing in controlled environments, to ensure their products meet stringent quality benchmarks.

china centrifugal slurry pump parts factories

3. Research and Development

Innovation is vital for maintaining competitiveness in the global market. Many Chinese factories invest in research and development (R&D) to improve pump efficiency and extend the lifespan of their components. Innovations may include developing new materials that can withstand severe abrasion or designing impellers that enhance flow rates and reduce energy consumption.

The Impact of Globalization

With globalization, Chinese manufacturers have successfully penetrated international markets. Many factories export their products worldwide and have established partnerships with companies across North America, Europe, and Australia. This global outreach has been facilitated by improved logistics, trade agreements, and the ability to meet international demand for high-performance slurry pumps and parts.

Environmental Considerations

As environmental concerns grow, Chinese manufacturers are also adapting to meet sustainability standards. Efforts to reduce energy consumption during production processes and the development of eco-friendly materials for slurry pump parts are becoming common practices. Manufacturers are increasingly focusing on creating products that not only perform well but also minimize environmental impact.

Challenges in the Industry

Despite the successes, there are challenges that manufacturers face, including intense competition and fluctuating raw material prices. The pressure to keep costs down while improving technology and adhering to quality standards can be difficult. Additionally, international trade policies and tariffs may also affect export dynamics for Chinese manufacturers.

Conclusion

The centrifugal slurry pump parts factories in China play a vital role in the global supply chain for industrial pumping solutions. With advanced manufacturing capabilities, a strong emphasis on quality control, and ongoing investment in research and development, these factories deliver products that meet the demands of various industries. While challenges remain, the future looks promising for Chinese manufacturers in this sector, as they continue to innovate and expand their reach in the global market. Whether you are in need of high-quality slurry pumps or replacement parts, considering suppliers from these factories can be a strategic decision for businesses aiming for reliability and performance in their operations.

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025