දෙසැ. . 25, 2024 18:26 Back to list

Top Slurry Pump Manufacturers and Factories in the USA for Quality Solutions

The Role of Slurry Pumps in U.S. Factories An Overview

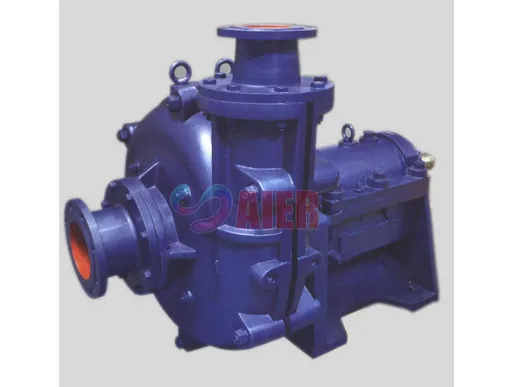

Slurry pumps are vital components in various industrial processes, particularly in factories across the United States. These specialized pumps are designed to handle mixtures of liquids and solids, also known as slurries, which can be challenging to transport. This article explores the functioning, applications, and importance of slurry pumps in U.S. factories, highlighting their contribution to efficiency and productivity in numerous sectors.

Understanding Slurry Pumps

Slurry pumps are engineered to move slurries — mixtures of liquids, solids, and sometimes gases. This process can be challenging due to the abrasive and corrosive nature of some materials, such as minerals, cement, coal, and waste products from manufacturing processes. Unlike standard pumps, slurry pumps are built to withstand wear and tear, featuring robust materials and designs that reduce maintenance costs and downtimes.

The working principle of a slurry pump involves using an impeller to create a centrifugal force that pushes the slurry through the pump and into piping systems. The design of the pump, including the shape of the impeller and casing, is crucial in determining its efficiency and capability to handle high-density slurries. Key factors such as pump configuration, material selection, and proper sizing are essential for optimal performance in industrial settings.

Applications in U.S. Factories

In the United States, slurry pumps are employed in a variety of industries, including mining, construction, wastewater treatment, and food processing.

1. Mining Industry One of the primary applications of slurry pumps is in the mining sector, where they are used to transport mined minerals and ore slurries from extraction sites to processing facilities. This task is vital, especially in the production of critical raw materials such as coal, gold, and copper. The durability of slurry pumps helps miners to maintain consistent production levels while minimizing equipment failure.

slurry pump usa factories

2. Construction In construction, slurry pumps facilitate the movement of cement and other construction materials. In addition, they play a crucial role in dewatering sites, preventing water accumulation during excavation and foundation work. Their ability to handle viscous mixtures makes them indispensable in modern construction practices.

3. Wastewater Treatment In wastewater treatment facilities, slurry pumps are essential for transporting sludge and other waste materials through various treatment processes. Efficient circulation of slurry ensures that the treatment process runs smoothly and meets environmental regulations. Factories that produce waste must manage their byproducts effectively, and slurry pumps help streamline this process.

4. Food Processing Interestingly, slurry pumps also find their use in the food processing industry. They are employed to transport various mixtures, including fruit and vegetable pulps, sauces, and dairy products. The sanitary design of certain slurry pumps is crucial to ensure compliance with health regulations and to maintain product quality.

The Importance of Efficiency and Reliability

The efficiency and reliability of slurry pumps can directly impact the overall productivity of a factory. When these pumps operate correctly, they enhance the flow of materials, reduce energy consumption, and lower operational costs. On the other hand, pump failures can lead to significant losses, including production downtimes and increased maintenance expenses. Therefore, selecting the right slurry pump and implementing a preventive maintenance program are critical for sustainable operations.

Moreover, as industrial processes evolve and the demand for more advanced and environmentally friendly practices grows, the development of innovative slurry pump technologies becomes imperative. U.S. manufacturers are continually improving the design and materials used in slurry pumps to enhance their efficiency, reduce energy usage, and minimize environmental impacts.

Conclusion

Slurry pumps serve a crucial function in U.S. factories, playing a significant role in transporting materials across various industries. Their ability to handle challenging mixtures makes them invaluable in mining, construction, wastewater treatment, and food processing. As industries strive for greater efficiency and sustainability, the importance of reliable and advanced slurry pump technology will only increase. Investing in high-quality slurry pumps and maintenance practices is essential for factories aiming to maintain productivity and competitive edge in the ever-evolving industrial landscape.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025