Oct . 13, 2024 02:06 Back to list

Slurry Pump Replacement Parts and Maintenance Solutions for Optimal Performance

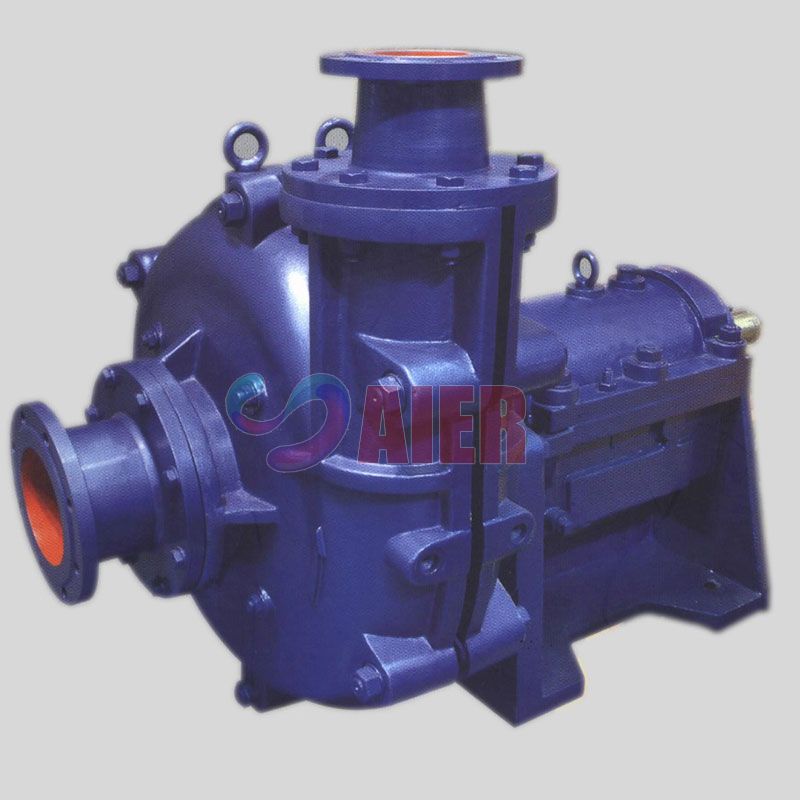

Understanding Slurry Pump Spare Parts Essential Components for Optimal Performance

Slurry pumps are vital equipment in industries such as mining, construction, and wastewater treatment, where the transport of abrasive and viscous materials is essential. These pumps are specifically designed to handle mixtures of liquids and solids, known as slurries. Given their heavy-duty function, slurry pumps operate under challenging conditions, leading to wear and tear over time. Therefore, understanding slurry pump spare parts is crucial for maintaining their efficiency and prolonging their lifespan.

Importance of Spare Parts

Spare parts for slurry pumps ensure that the equipment remains functional and efficient, especially when dealing with abrasive materials that can cause significant wear on pump components. Regular maintenance and timely replacement of worn parts not only enhance pump performance but also prevent unexpected breakdowns, which can lead to costly production downtime.

Key Spare Parts for Slurry Pumps

1. Impellers The impeller is one of the most critical components of a slurry pump. It is responsible for imparting energy to the slurry, enabling its movement through the pump. Impellers are subject to wear due to the abrasive nature of the materials they handle. Choosing the right impeller material—such as high chrome or rubber—depending on the application's specific requirements is essential for maximizing lifespan and performance.

2. Casing The casing contains the impeller and holds the slurry inside the pump. Like the impeller, it is also prone to erosion and wear. Maintaining the integrity of the casing is vital, as any damage can lead to leakage and reduced efficiency. Spare casings, designed with different materials, can be used to replace worn-out casings, depending on the operating environment.

3. Suction and Discharge Hoses These hoses are critical for directing the flow of slurry into and out of the pump. They must be durable enough to withstand the abrasive materials and the pressures involved in pumping operations. Regular inspection and replacement of hoses prevent blockages and ensure smooth operation.

4. Seal Kits Seals play a crucial role in preventing leaks around rotating components. Over time, seals can wear and become ineffective, leading to leaks that can cause environmental hazards and disrupt operations. Regularly replacing seal kits during scheduled maintenance can prevent such issues and ensure the longevity of the pump.

5. Wear Plates These are protective components that are installed to absorb wear and tear caused by the abrasive slurries being pumped. Wear plates are generally made from tough materials, allowing them to withstand harsh operating conditions. Replacing wear plates as part of a routine maintenance schedule can protect other more critical parts of the pump.

slurry pump spare parts

6. Bearings and Shaft Bearings support the rotating elements of the pump and ensure smooth operation. Shafts transmit the mechanical energy from the motor to the impeller. Given the heavy load and abrasive environment, these components can suffer significant wear over time. Regular inspection and timely replacement of bearings and shafts are necessary to maintain efficient pump operation.

Best Practices for Managing Spare Parts

To effectively manage slurry pump spare parts and maintain operational efficiency, consider the following best practices

- Inventory Management Maintain an inventory of critical spare parts to minimize downtime in the event of a failure. Establishing a reorder point can ensure that essential parts are always on hand when needed.

- Regular Maintenance Create and adhere to a regular maintenance schedule. This includes inspections, cleaning, and replacing worn or damaged parts. Addressing issues before they lead to catastrophic failures can save time and money.

- Training and Expertise Ensure that personnel responsible for maintaining slurry pumps are well-trained in the specifics of the equipment. Understanding the operational parameters and the wear characteristics of different parts can enhance maintenance effectiveness.

- Supplier Relationships Develop strong relationships with reliable spare parts suppliers. This can facilitate timely access to quality components, reducing lead times for repairs.

Conclusion

In conclusion, slurry pump spare parts are essential for optimizing performance, extending the lifespan of the equipment, and ensuring smooth operations across various industries. By understanding the key components, implementing effective maintenance practices, and staying proactive about spare parts management, businesses can enhance their operational efficiency and reduce unforeseen downtime. Investing in the right spare parts and adhering to a routine maintenance program is crucial for the reliability of slurry pumps in handling challenging materials.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025