Дек . 20, 2024 04:08 Back to list

high quality chemical centrifugal slurry pump

High-Quality Chemical Centrifugal Slurry Pumps A Comprehensive Overview

In the modern industrial landscape, efficient material handling is crucial for operational success, especially in sectors such as mining, agriculture, and chemical processing. One of the pivotal components for effective material transfer is the chemical centrifugal slurry pump. This article delves into the features, benefits, applications, and maintenance of high-quality chemical centrifugal slurry pumps.

Understanding Chemical Centrifugal Slurry Pumps

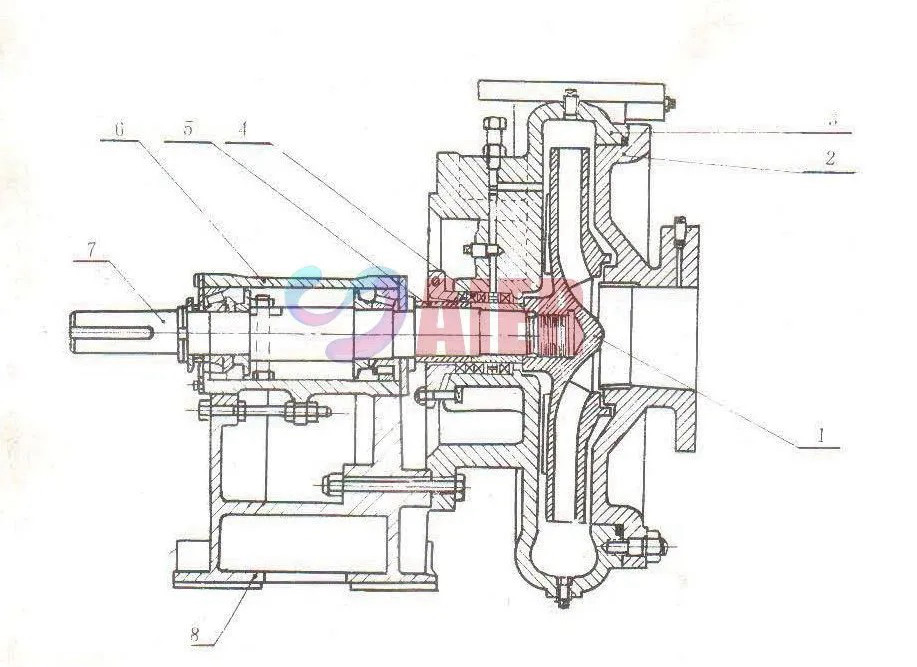

Chemical centrifugal slurry pumps are specialized pumps designed to handle aggressive and abrasive fluids, particularly mixtures of liquid and solid particles, known as slurries. The centrifugal pump mechanism works by converting mechanical energy, derived from the pump's rotating impeller, into hydraulic energy, which moves the slurry through the piping system. These pumps are engineered to manage a wide variety of chemical compositions while maintaining durability and efficiency.

Key Features of High-Quality Pumps

1. Material Construction High-quality chemical centrifugal slurry pumps are often constructed from corrosion-resistant and wear-resistant materials such as stainless steel, high chrome alloy, or rubber-lined designs. These materials enhance the longevity of the pump while minimizing maintenance needs in harsh chemical environments.

2. Operational Efficiency Advanced pump designs emphasize high efficiency and energy conservation. These pumps are engineered to reduce hydraulic losses, ensuring that they can operate under high-pressure conditions without excessive energy consumption.

3. Customizable Designs The best slurry pumps offer customizable features to fit specific operational needs. Options may include varying impeller sizes, pump orientations, and configurations tailored to the unique chemistry and viscosity of the slurry being handled.

4. Modular Components Quality pumps often have modular components that facilitate easy maintenance and repairs. This design minimizes downtime by allowing quick replacements of wear parts without the need for extensive disassembly.

Benefits of Using Chemical Centrifugal Slurry Pumps

1. Enhanced Durability Due to their robust construction, high-quality chemical centrifugal slurry pumps have a longer operational life compared to conventional pumps. They resist wear from abrasive particles, which is a critical factor when handling slurries.

2. Cost-effectiveness While the initial investment for high-quality pumps may be higher, their efficiency and durability lead to significant savings on maintenance costs and operational downtime. Over time, the total cost of ownership is often lower than that of cheaper, less durable alternatives.

high quality chemical centrifugal slurry pump

3. Versatility These pumps can handle various slurry types, including those found in mineral processing, wastewater treatment, food processing, and chemical manufacturing. This versatility makes them essential across multiple industries.

4. Simplicity of Operation Advanced design features often result in user-friendly operation. Many high-quality pumps include automated controls and monitoring systems that enhance operational efficiency and enable easier management of complex processes.

Applications of Chemical Centrifugal Slurry Pumps

High-quality chemical centrifugal slurry pumps find applications across diverse industries

- Mining and Minerals They transport slurry containing minerals, ores, and tailings, facilitating efficient processing and extraction activities.

- Chemical Processing These pumps handle corrosive and abrasive materials, including acids and slurries produced during chemical reactions, ensuring safe and effective material transfer.

- Wastewater Management In wastewater treatment facilities, these pumps manage sludge and other solid-liquid mixtures, playing a vital role in the treatment and recycling processes.

- Food and Beverage The ability to handle varying viscosity and solid contents makes these pumps suitable for applications in the food processing industry, particularly in the production of sauces, pastes, and other mixtures.

Maintenance Considerations

To ensure the longevity and reliable performance of chemical centrifugal slurry pumps, regular maintenance is essential. Key maintenance practices include

- Routine Inspections Regularly check for signs of wear, corrosion, or leaks. - Lubrication Ensure that bearings and other moving parts receive appropriate lubrication. - Impeller and Casing Checks Inspect impeller and casing for wear and replace damaged components as necessary.

In conclusion, high-quality chemical centrifugal slurry pumps are integral to the operational success of various industries dealing with abrasive and corrosive materials. Their durability, efficiency, and versatility make them indispensable in achieving optimal material handling and processing outcomes. Whether in mining, chemical processing, or wastewater management, investing in these advanced pumps is a strategic decision that can significantly enhance productivity and profitability.

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025

-

Heavy Duty Submersible Pumps Robust & Reliable Solutions

NewsJun.09,2025