Dec . 26, 2024 02:47 Back to list

high quality vertical chemical sump pump

High-Quality Vertical Chemical Sump Pump A Key Component for Industrial Applications

In the realm of industrial processes, the handling of various chemicals safely and efficiently is paramount. Among the essential equipment that aids in this endeavor is the high-quality vertical chemical sump pump. These pumps are specifically designed to manage the challenges associated with transferring corrosive and abrasive materials while ensuring safety, durability, and reliability.

What is a Vertical Chemical Sump Pump?

A vertical chemical sump pump is engineered to function in low-level liquid environments, typically found in sumps or pits where liquids accumulate. Unlike standard pumps, these vertical units are submerged beneath the liquid surface, drawing fluids upwards through a vertical design. This ensures that the pump operates efficiently even in confined spaces, making it a versatile choice for various industrial applications such as chemical processing, wastewater management, and mining operations.

Key Features of High-Quality Vertical Chemical Sump Pumps

1. Material Construction One of the most critical aspects of a high-quality vertical chemical sump pump is the materials used in its construction. Pumps designed for chemical handling are typically made from corrosion-resistant materials such as stainless steel, PVC, or polypropylene. This ensures longevity and reduces the likelihood of pump failure due to chemical degradation.

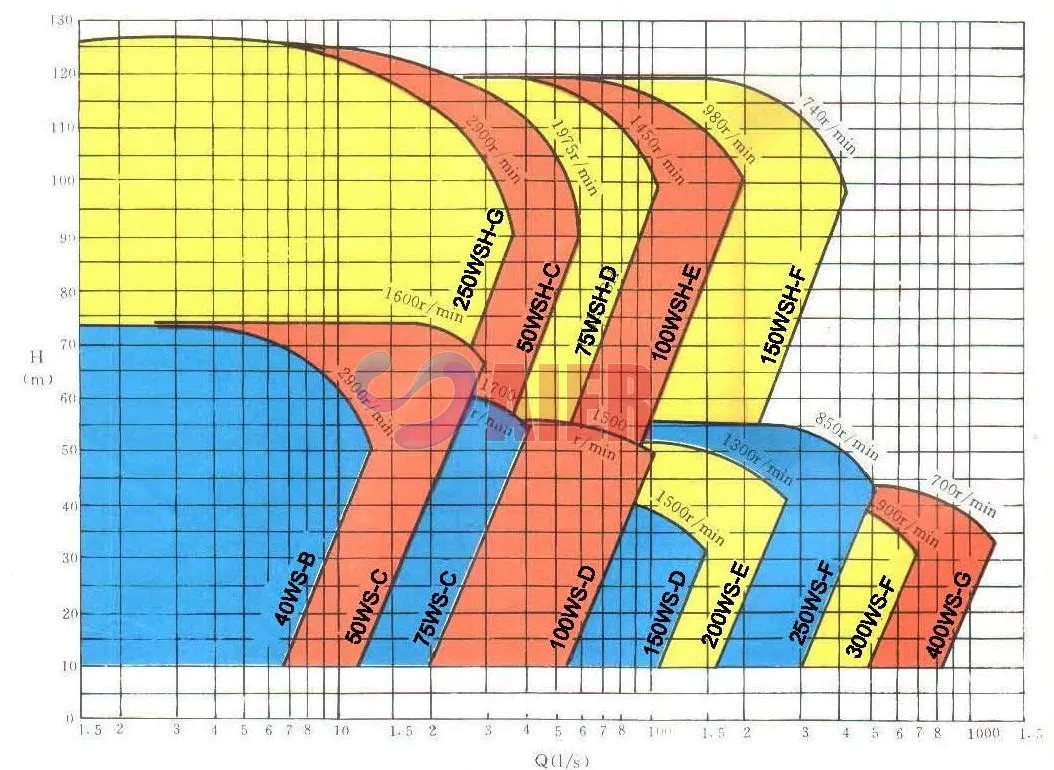

2. Flow Rate and Head Pressure These pumps can be designed to operate at various flow rates and head pressures, depending on the specific needs of the application. Providers often offer customizable options to match the pump’s output capabilities with the demands of the system it will serve.

3. Seal and Bearing Design High-quality sump pumps utilize advanced sealing technologies to prevent leaks and maintain operational integrity. This is crucial when dealing with hazardous materials. Moreover, durable bearings reduce friction and heat, contributing to the smooth operation of the pump.

high quality vertical chemical sump pump

4. Ease of Maintenance A significant concern in industrial settings is the ease of maintenance. Top-tier vertical chemical sump pumps are designed for simplicity in serviceability, featuring easy-access components and assemblies. This minimizes downtime, allowing industries to maintain productivity.

5. Energy Efficiency With increasing energy costs, selecting a pump that operates efficiently can lead to significant savings. High-quality pumps are designed with energy-efficient motors and hydraulic systems that optimize performance while minimizing energy consumption.

Applications in Various Industries

Vertical chemical sump pumps find their applications across a spectrum of industries. In the chemical processing sector, they are essential for transferring acids, alkalis, and other corrosive substances. In wastewater treatment facilities, these pumps aid in managing sludge and other residuals that can pose environmental hazards. Additionally, in the mining industry, they play a crucial role in dewatering operations to keep mines operational and safe.

Conclusion

Investing in a high-quality vertical chemical sump pump not only ensures the efficient transfer of chemicals but also bolsters safety and minimizes environmental risks. With their durable construction, ease of maintenance, and design adaptability, these pumps stand out as vital components in various industrial applications. As industries continue to prioritize safety and efficiency in their operations, understanding the value of high-quality equipment like vertical chemical sump pumps will remain critical.

Choosing the right pump involves careful consideration of design specifications, material compatibility, and application needs. By leveraging advanced technology and engineering, high-quality vertical chemical sump pumps continue to support critical processes across multiple sectors, embodying innovation and reliability in the face of challenging operational environments.

-

Innovative Small Dredgers and Marine Pontoon Solutions from Aier Machinery Hebei Co., Ltd.-Reliable Dredging Equipment&Customizable Marine Pontoons

NewsAug.09,2025

-

Small Dredger and Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Marine Dredge Pump Manufacturers,Gold Dredging Boat

NewsAug.09,2025

-

Small Dredger & Marine Pontoon - Aier Machinery | Durable Dredging Tech

NewsAug.09,2025

-

Wholesale Slurry Pump Spare Parts Cover Plate - Factory Direct

NewsAug.09,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Dredging Solutions&Material Handling

NewsAug.09,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Industrial Efficiency, Marine Solutions

NewsAug.08,2025