Feb . 19, 2025 12:12 Back to list

OEM Castings

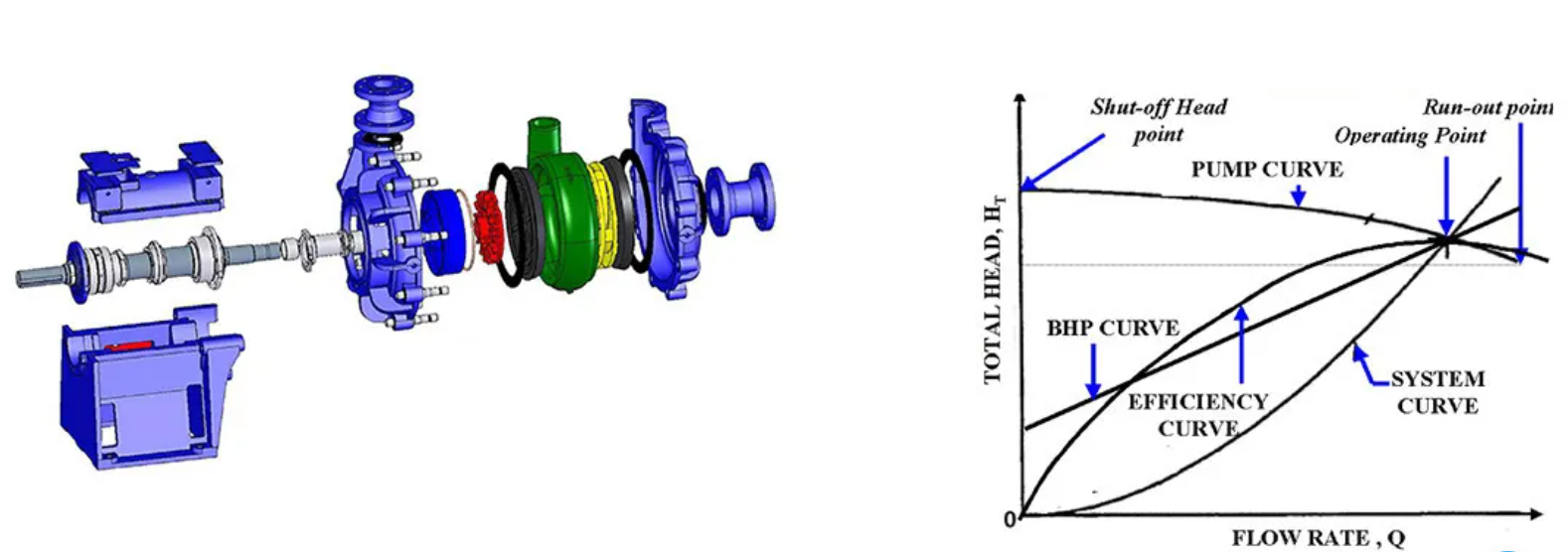

The high quality metal lined slurry pump has emerged as a pivotal component in the industrial domain, offering unparalleled efficiency, durability, and reliability in handling abrasive and corrosive slurries. Renowned for their robustness, these pumps are engineered to withstand the harshest environments, ensuring sustained operational effectiveness in mining, construction, and chemical processing industries.

Trustworthiness is fortified through rigorous testing and adherence to international standards. Before reaching the market, each metal lined slurry pump undergoes a series of stress and performance tests under simulated environmental conditions. Manufacturers are committed to transparency, providing detailed reports and certificates of compliance from third-party testing organizations. This dedication to quality assurance guarantees that every pump delivered will perform to the highest standards expected by the most demanding industries. The practical benefits of high quality metal lined slurry pumps are manifold. They provide exceptional performance in terms of flow rate and pressure management, ensuring seamless operation in critical processes. This not only saves energy but also translates to significant cost savings over the pump's lifespan. Designed for easy maintenance, these pumps allow for quick and straightforward access to components, reducing downtime during routine inspections or repairs. Furthermore, advancements in materials science contribute to the evolving nature of these pumps. Continuous research and development efforts have led to the incorporation of advanced alloys and coatings, which enhance the metal linings’ resistance to extreme temperatures and chemical reactions. This innovation not only bolsters the pumps' efficacy but also extends their application range, making them a versatile solution across various industry sectors. In conclusion, high quality metal lined slurry pumps are indispensable tools in modern industrial operations, delivering unmatched performance, reliability, and adaptability. Their design reflects a deep understanding of industrial needs, supported by expertise and rigor in engineering. With endorsements from authoritative bodies and proven track records, they stand as a testament to trustworthiness in pumping solutions. As industries continue to evolve, these pumps are poised to remain at the forefront, embodying the pinnacle of technological progress and engineering excellence in handling challenging materials.

Trustworthiness is fortified through rigorous testing and adherence to international standards. Before reaching the market, each metal lined slurry pump undergoes a series of stress and performance tests under simulated environmental conditions. Manufacturers are committed to transparency, providing detailed reports and certificates of compliance from third-party testing organizations. This dedication to quality assurance guarantees that every pump delivered will perform to the highest standards expected by the most demanding industries. The practical benefits of high quality metal lined slurry pumps are manifold. They provide exceptional performance in terms of flow rate and pressure management, ensuring seamless operation in critical processes. This not only saves energy but also translates to significant cost savings over the pump's lifespan. Designed for easy maintenance, these pumps allow for quick and straightforward access to components, reducing downtime during routine inspections or repairs. Furthermore, advancements in materials science contribute to the evolving nature of these pumps. Continuous research and development efforts have led to the incorporation of advanced alloys and coatings, which enhance the metal linings’ resistance to extreme temperatures and chemical reactions. This innovation not only bolsters the pumps' efficacy but also extends their application range, making them a versatile solution across various industry sectors. In conclusion, high quality metal lined slurry pumps are indispensable tools in modern industrial operations, delivering unmatched performance, reliability, and adaptability. Their design reflects a deep understanding of industrial needs, supported by expertise and rigor in engineering. With endorsements from authoritative bodies and proven track records, they stand as a testament to trustworthiness in pumping solutions. As industries continue to evolve, these pumps are poised to remain at the forefront, embodying the pinnacle of technological progress and engineering excellence in handling challenging materials.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025