Aug . 08, 2024 05:25 Back to list

High-Performance Rubber Slurry Pump for Efficient Transport of Abrasive Materials and Fluids

Understanding the 8-6% Rubber Slurry Pump An Essential Tool for Industry

In various industrial sectors, effective and efficient fluid handling is paramount, especially when dealing with abrasive and viscous materials like slurries. One of the standout solutions in this domain is the 8-6% rubber slurry pump, a specialized type of pump designed to handle slurries with a high solid content. This article explores the salient features, applications, and advantages of the 8-6% rubber slurry pump in modern industries.

Features of the 8-6% Rubber Slurry Pump

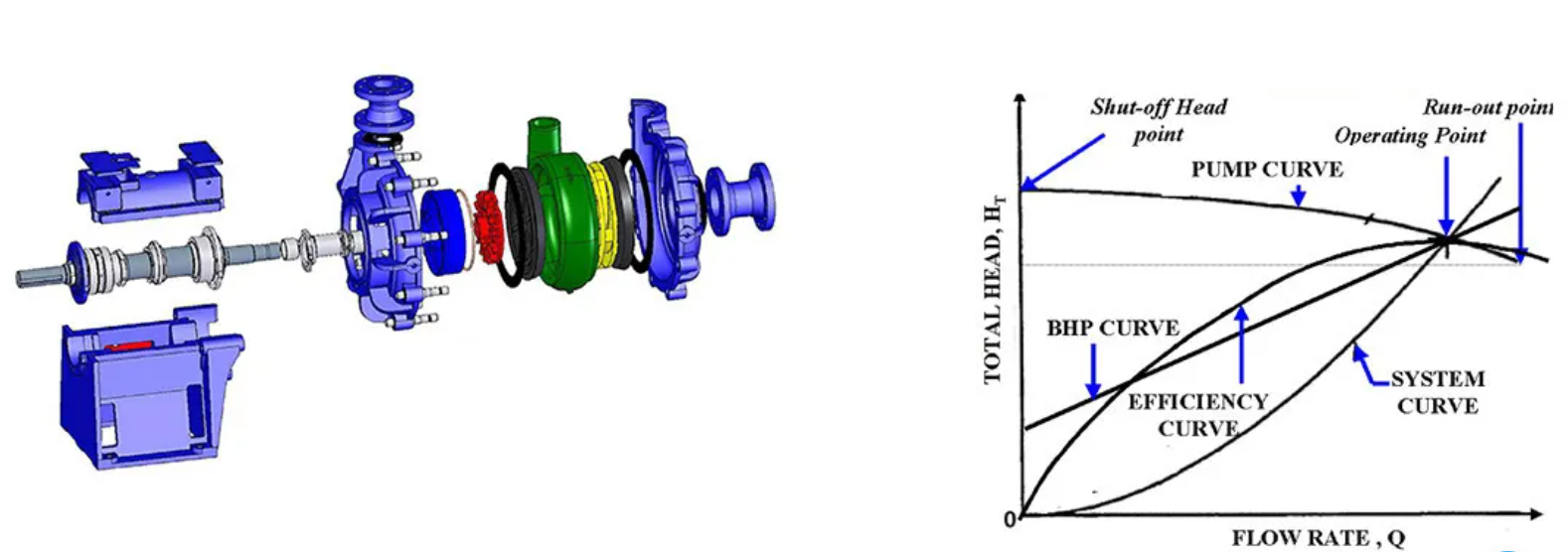

The nomenclature 8-6 refers to the pump's nominal size, where 8 indicates the inlet diameter (in inches) and 6 signifies the discharge diameter. This pump is characterized by its robust construction, primarily using high-quality rubber materials. The rubber lining provides a superior wear resistance against the harsh and abrasive nature of the slurries it handles, thus extending the pump's operational life.

Moreover, the design of the 8-6% rubber slurry pump incorporates a centralized bearing assembly, ensuring stable operation even under high-pressure conditions. Its horizontal orientation allows for a more straightforward installation and maintenance process, crucial for minimizing downtime in industrial settings. The pump's hydraulic design is optimized for high efficiency, providing excellent flow rates and pressurization without compromising on performance.

Applications in Diverse Industries

The versatility of the 8-6% rubber slurry pump makes it suitable for various applications across several industries. In mining and mineral processing, it is extensively used for transporting tailings, concentrates, and other types of slurry. The ability to handle abrasive materials without significant wear and tear makes it a preferred choice in this sector.

In the construction industry, the pump facilitates the movement of cement slurries, excavated material, and other aggregates, enhancing productivity and efficiency on-site. Wastewater treatment facilities also benefit from the 8-6% rubber slurry pump, as it aids in the transportation of sludge and other viscous waste materials through the treatment process.

8-6 rubber slurry pump

Additionally, the chemical processing sector leverages the pump for its capability to handle corrosive slurries, thanks to the resilient rubber lining that can withstand various chemical compositions. This wide range of applications demonstrates the pump's integral role in optimizing operations across multiple fields.

Advantages of the 8-6% Rubber Slurry Pump

The primary advantage of the 8-6% rubber slurry pump lies in its durability. The rubber components are specifically designed to resist wear from solids within the slurry, which significantly reduces maintenance costs over time. Furthermore, the ease of maintenance due to the pump's design allows for quick repairs and part replacements, ultimately minimizing downtime.

Another significant benefit is the efficiency of operation. The optimal hydraulic design of the 8-6% pump ensures that it can handle high flow rates with minimal energy consumption, making it an economically viable option for industries where operational costs are a concern.

Lastly, the customization options for the 8-6% rubber slurry pump offer flexibility to industries. It can be tailored to meet specific operational conditions, whether for different slurry compositions or varying flow rates, ensuring that each application receives the most effective pumping solution available.

Conclusion

The 8-6% rubber slurry pump is undoubtedly a vital tool in modern industrial processes, combining durability, efficiency, and versatility. Its ability to handle challenging materials without compromising performance makes it an invaluable asset across various sectors. As industries continue to evolve and adapt to new challenges, the significance of such specialized equipment will only continue to grow, ensuring that operations remain smooth and effective.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025