lis . 26, 2024 14:40 Back to list

Compact submerged slurry pump for versatile and efficient fluid transfer applications

The Portable Submersible Slurry Pump A Versatile Solution for Challenging Environments

In industries ranging from construction to mining, the effective management of liquids and sludges is crucial. One of the key tools for handling such tasks has been the portable submersible slurry pump. These specialized pumps are designed to efficiently transport a mixture of liquids and solids, allowing for clean, effective, and safe operations in challenging environments. This article explores the features, benefits, applications, and maintenance of portable submersible slurry pumps, highlighting their significance in various industries.

What is a Portable Submersible Slurry Pump?

A portable submersible slurry pump is a type of pump designed to operate underwater, submerging entirely in the liquids it is meant to move. Unlike traditional pumps that often require a priming process and are installed above the liquid’s surface, submersible pumps eliminate the need for priming by being situated directly within the fluid. This allows them to handle a mixture of water and solid materials, also known as slurry. The construction of these pumps typically features a robust design, incorporating materials that enhance their durability and resistance to abrasion, which is vital when handling abrasive materials.

Key Features

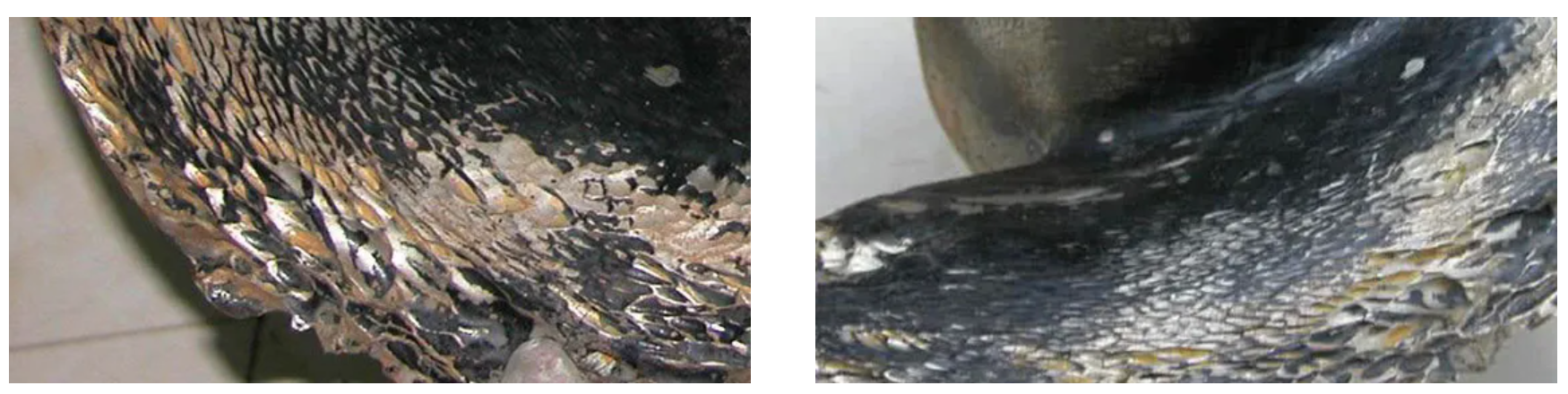

1. Durability Most portable submersible slurry pumps are made from high-quality materials such as stainless steel and hardened cast iron, allowing them to withstand harsh conditions and resist wear from abrasive slurries.

2. Versatility These pumps can handle various slurries, including mud, sand, and even heavy sludge, making them highly applicable in construction sites, wastewater treatment plants, and mining operations.

3. Ease of Transport With portability being a key factor, these pumps are often lightweight and come with handles or frames that enable easy movement from one site to another.

4. Submersible Design Their design enables them to work in deeper liquid levels, navigating submerged conditions efficiently, and minimizing the risk of cavitation, which can damage pumps.

Applications

Portable submersible slurry pumps are employed in a variety of applications

- Construction Sites They are extensively used for dewatering excavation sites, where they remove excess water and slurry created by digging operations

.- Mining Operations In mining, they help in transporting slurry containing ore, making it easier to manage varying levels of water and material.

- Wastewater Management These pumps are instrumental in sludge pumping and dewatering processes in wastewater treatment facilities.

portable submersible slurry pump

- Flood Control During flood conditions, portable submersible slurry pumps can act quickly to remove water from affected areas, providing essential support in emergency situations.

Benefits

The use of portable submersible slurry pumps brings numerous advantages

- Increased Efficiency Their ability to pump both liquid and solid materials saves time and resources compared to traditional pumping methods.

- Reduced Downtime Their portable nature allows for quick setup and relocation, reducing downtime and increasing productivity on job sites.

- Cost-Effectiveness Investing in a high-quality portable submersible slurry pump can lead to lower operational costs over time due to its durability and efficiency.

Maintenance Tips

Maintaining a portable submersible slurry pump is essential for its longevity and performance. Here are some maintenance tips

1. Regular Inspection Check the pump for signs of wear and tear, particularly the impeller and casing.

2. Keep it Clean Ensure that any abrasive materials do not clog the pump, which can lead to performance issues.

3. Monitor Electrical Components For electric pumps, inspect and maintain wiring and connections to prevent electrical failures.

4. Lubrication Regularly lubricate the pump’s bearings per the manufacturer’s recommendations.

Conclusion

The portable submersible slurry pump is an invaluable asset across various industries, offering efficiency, versatility, and durability in managing challenging liquid and solid mixtures. By understanding their features, applications, and maintenance requirements, operators can leverage these pumps to streamline processes, enhance productivity, and ensure effective liquid management in a wide range of environments. Whether in construction, mining, or environmental management, these pumps are designed to meet the demands of modern industry with finesse.

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025