Dec . 01, 2024 00:15 Back to list

centrifugal slurry pump liner factory

The Importance of Centrifugal Slurry Pump Liners in Industrial Applications

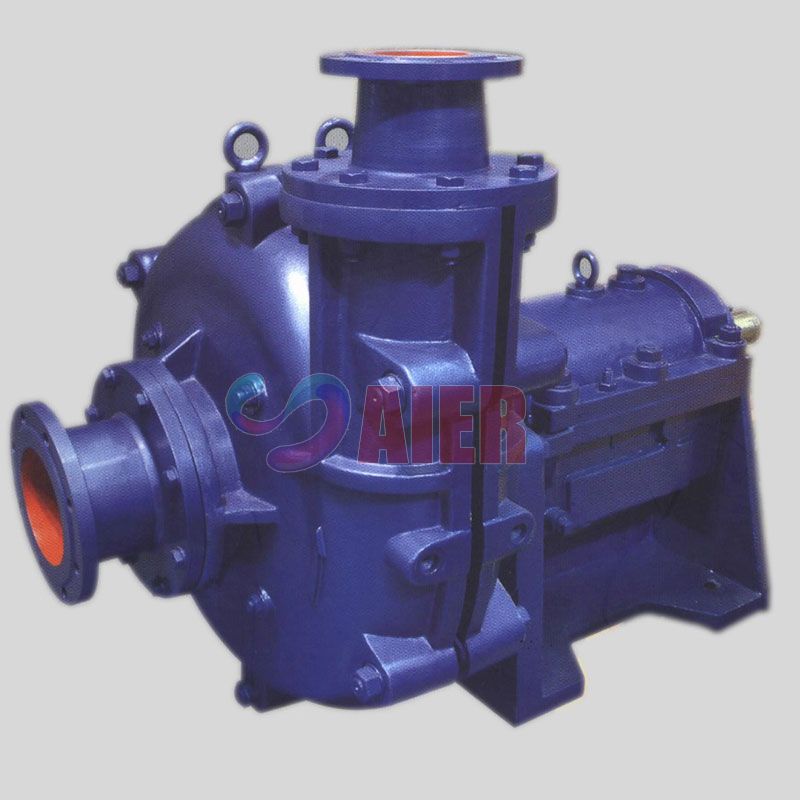

In the realm of industrial pumps, centrifugal slurry pumps play a pivotal role in transporting abrasive and viscous materials. These pumps are particularly invaluable in sectors such as mining, mineral processing, and wastewater management, where the handling of slurries—mixtures of solids and liquids—is commonplace. A crucial component of these pumps is the liner, which significantly influences the pump's efficiency, longevity, and overall performance.

The Importance of Centrifugal Slurry Pump Liners in Industrial Applications

For instance, rubber liners are favored for their excellent impact resistance and flexibility, making them suitable for applications involving large particles and high flow rates. On the other hand, metal liners, often made from alloyed steel, are designed for extremely abrasive environments and can withstand higher temperatures and pressure levels. Polyurethane liners represent a hybrid solution, offering both flexibility and durability while resisting chemical corrosion.

centrifugal slurry pump liner factory

The manufacturing processes for centrifugal slurry pump liners have evolved over the years, driven by advancements in technology and materials science. Modern factories utilize precision engineering techniques, such as computer-aided design (CAD) and computer numerical control (CNC) machining, to produce liners that meet stringent quality standards. This technological progression not only enhances the performance of the liners but also improves their consistency and reproducibility.

When sourcing centrifugal slurry pump liners, it is essential to consider several factors. The liner’s compatibility with the specific type of slurry being pumped, the operational conditions (including temperature and pressure), and the expected wear rates are critical parameters that dictate the choice of liner material. A well-matched liner can markedly extend the lifespan of the pump, reduce maintenance costs, and increase productivity.

Moreover, the availability of customized solutions is becoming increasingly popular in the liner manufacturing sector. Many factories now offer tailored liner designs that cater to specific client needs and operational challenges. Customization not only optimizes performance but also ensures that companies can achieve the highest efficiency in their processes, thereby enhancing overall profitability.

In conclusion, the role of centrifugal slurry pump liners may often be overlooked, yet they are fundamental in ensuring the reliable and efficient operation of pumps in demanding industrial environments. By investing in high-quality liners that are produced in technologically advanced factories, industries can safeguard their operations against wear-related failures and optimize their slurry transport processes. As industries continue to evolve, the demand for innovative and durable lining solutions will certainly grow, prompting ongoing research and development in this critical area of pump technology.

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025

-

High Quality Warman Slurry Pump Drawings Supplier & Factory Reliable Customization

NewsJul.06,2025

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025