Oct . 06, 2024 17:54 Back to list

impeller for slurry pump factories

Impeller for Slurry Pump Factories A Key Component in Efficient Pumping Solutions

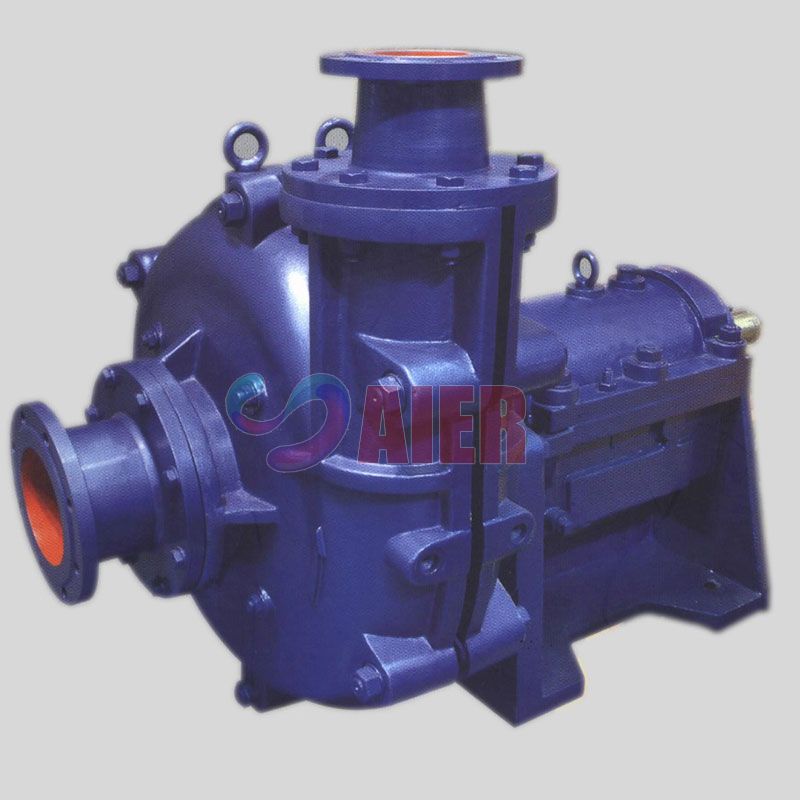

In the world of fluid handling, particularly in the mining, construction, and wastewater industries, slurry pumps play a vital role in transporting thick, abrasive mixtures of solids and liquids. At the heart of these pumps lies the impeller, a crucial component whose design and functionality significantly impact the overall performance of the slurry pump. Understanding the importance of impeller design in slurry pump factories is essential for improving efficiency and reducing maintenance costs.

Impeller for Slurry Pump Factories A Key Component in Efficient Pumping Solutions

Slurry pump factories focus on producing impellers that are tailored to various applications. Materials utilized in the manufacture of impellers are critical, given the abrasive nature of slurries. High-chrome alloys or elastomeric materials are often employed for their durability and resistance to wear. Additionally, the shape and size of the impeller must be designed to withstand the hydraulic forces exerted by the slurry flow, which can lead to cavitation and erosion if not adequately managed.

impeller for slurry pump factories

The innovation in impeller design is also driven by advancements in technology. Computational fluid dynamics (CFD) simulations and 3D printing have revolutionized the way impellers are designed and tested. CFD allows engineers to visualize flow patterns within the pump, enabling them to make data-driven decisions about impeller shapes that improve hydraulic performance. Meanwhile, 3D printing provides a means to create complex designs that would be difficult or impossible to achieve using traditional manufacturing techniques.

Moreover, slurry pump factories are increasingly focusing on environmentally friendly practices. The production of impellers with reduced environmental impact is becoming a priority, as industries strive to meet sustainability goals. This includes utilizing recyclable materials and optimizing designs to ensure energy-efficient operation throughout the product life cycle.

In conclusion, the impeller is a critical component of slurry pumps, and its design is paramount for achieving efficient and reliable performance. Slurry pump factories play an essential role in innovating and producing high-quality impellers that meet the diverse needs of various industries. As technology continues to evolve, the future of impeller design looks promising, potentially leading to even more advanced pumping solutions capable of handling the challenges posed by abrasive slurries. Investing in cutting-edge impeller technology is not just about enhancing performance, but also about ensuring sustainability and operational efficiency in fluid handling processes.

-

High Quality Warman Slurry Pump Drawings Supplier & Factory Reliable Customization

NewsJul.06,2025

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025