Sep . 22, 2024 07:48 Back to list

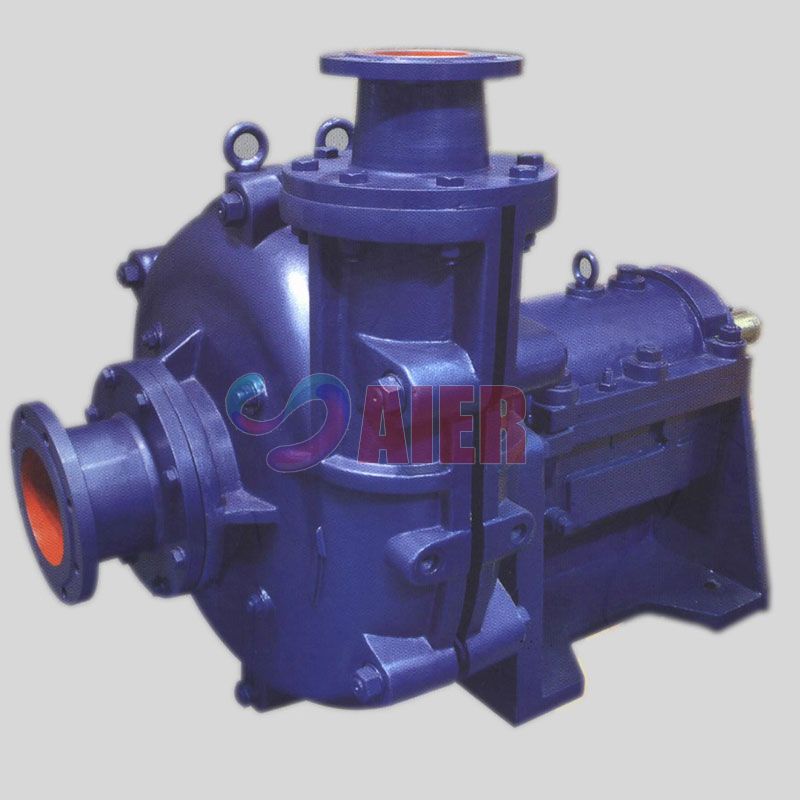

wholesale submersible slurry pump

Understanding Wholesale Submersible Slurry Pumps A Key Component in Industrial Applications

Submersible slurry pumps are essential in various industrial applications, particularly in those that involve the transfer of thick and abrasive liquids. These pumps, designed to operate underwater, have gained popularity in sectors such as mining, construction, and wastewater treatment. This article explores the key features, advantages, and wholesale purchasing considerations of submersible slurry pumps.

What are Submersible Slurry Pumps?

Submersible slurry pumps are specially engineered to handle heavy-duty materials, including slurries, sediments, and other viscous fluids. Unlike standard pumps that typically draw liquid from above the surface, submersible pumps are submerged in the fluid they are pumping, which significantly enhances their efficiency and performance in handling abrasive materials.

Key Features

1. Robust Construction These pumps are constructed from high-strength materials such as stainless steel or cast iron, making them durable and able to withstand the wear and tear associated with moving abrasive mixtures.

2. High Capacity Submersible slurry pumps come with powerful motors that facilitate the movement of large volumes of slurry, making them ideal for industrial applications where time and efficiency are critical.

3. Versatile Design Many submersible slurry pumps can handle solids of varying sizes, thus making them suitable for different applications, from construction sites to mining operations.

4. Energy Efficiency When submerged, these pumps require less energy to operate compared to conventional pumps, leading to reduced operational costs.

Advantages of Using Submersible Slurry Pumps

wholesale submersible slurry pump

- Reduced Labor Costs Since these pumps are designed to pump fluids directly from the source, they reduce the need for additional machinery and labor, thereby minimizing costs. - Lower Risk of Cavitation Operating underwater, submersible slurry pumps are less prone to cavitation, a phenomenon that can damage other types of pumps and lead to costly repairs. - Space-Saving As these pumps can operate submerged, they occupy less surface space, allowing for more efficient use of industrial sites.

Wholesale Purchasing Considerations

When considering wholesale purchase options for submersible slurry pumps, several factors need to be taken into account

1. Quality Assurance Ensure that the pumps meet industry standards and have a proven track record of durability and efficiency.

2. Supplier Reputation Opt for suppliers with a good reputation in the market. Reviews and testimonials can provide insights into their reliability and customer service.

3. Pricing and Discounts Compare quotes from different suppliers to find the best pricing. Wholesalers often provide discounts for bulk purchases, which can significantly lower costs.

4. After-sales Support Consider the availability of technical support and warranty services. A good after-sales service ensures that any issues can be resolved promptly, minimizing downtime.

5. Customization Options Depending on your application, you may need pumps tailored to specific requirements. Check if the wholesaler offers customization.

In conclusion, wholesale submersible slurry pumps play a pivotal role in enhancing operational efficiency across various industrial sectors. Their robust design, efficient functioning, and overall cost-effectiveness make them a preferred choice for businesses looking to optimize their fluid transfer processes. Understanding the features and advantages of these pumps can help in making informed purchasing decisions for long-term operational success.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025