Nov . 09, 2024 06:17 Back to list

High-Efficiency Rubber Lined Slurry Pump for Optimal Performance and Durability

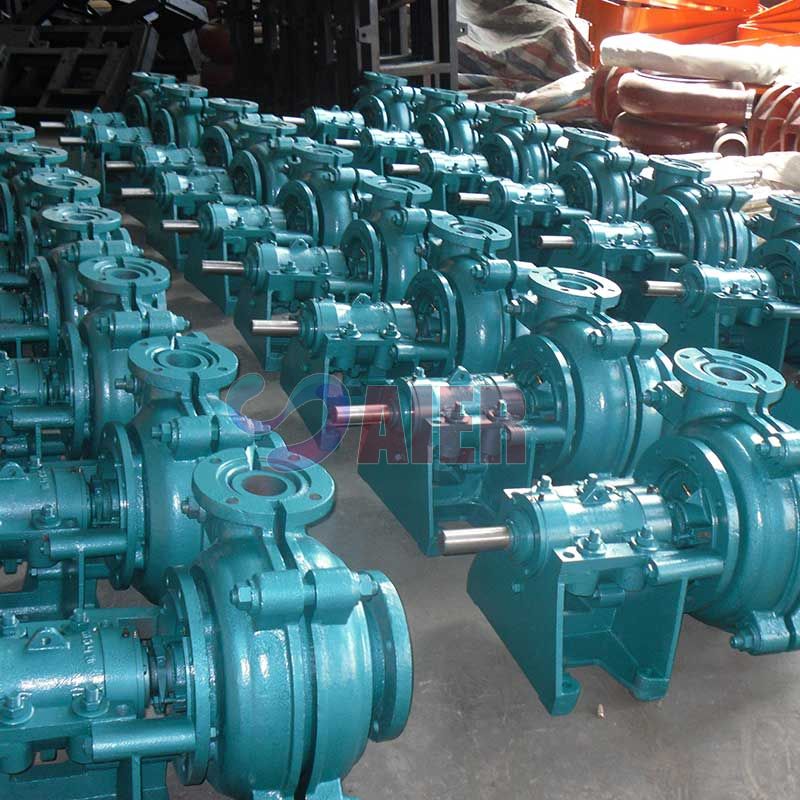

Warman Rubber Lined Slurry Pump An Overview

In the realm of industrial processes involving the transportation of abrasive and corrosive materials, the Warman rubber lined slurry pump stands out as a paragon of reliability and efficiency. These pumps are specifically designed to handle slurry, a mixture of solids and liquids, making them ideal for industries such as mining, mineral processing, and wastewater treatment.

Design and Construction

The Warman rubber lined slurry pumps are engineered to handle even the most challenging applications. The pump casing is lined with high-quality rubber, which provides excellent resistance to wear and corrosion. This is crucial, as slurries often contain abrasive particles that can quickly degrade traditional pump materials. The rubber lining not only extends the service life of the pump but also minimizes maintenance costs associated with wear parts replacement.

The impeller, another critical component, is typically made from a durable rubber compound that not only enhances efficiency but also allows for smooth operation in the harshest conditions. The design of the impeller also contributes to the pump's performance by maintaining a consistent flow rate and reducing turbulence, which can lead to cavitation—a phenomenon that can severely damage pumps.

Performance and Efficiency

One of the most significant advantages of Warman rubber lined slurry pumps is their exceptional hydraulic performance. These pumps are capable of handling a wide range of slurry concentrations and characteristics, making them versatile for various applications. They are available in different sizes and configurations, allowing industries to select the pump that best suits their specific needs.

The efficiency of these pumps is further enhanced by their ability to self-prime, which simplifies the operation process and reduces downtime. Additionally, they can handle high solids content and viscous slurries without compromising performance. This flexibility ensures that operations can continue smoothly, even in the face of changing material characteristics.

Applications

warman rubber lined slurry pump

Warman rubber lined slurry pumps are utilized in various applications across numerous industries. In the mining sector, they are primarily used for transferring coal, ores, and tailings. Their resilience to wear makes them the ideal choice for transporting materials that can be very abrasive.

In the mineral processing industry, these pumps facilitate the movement of slurries during various stages of production, from comminution to concentration. Their ability to handle high-density slurries while maintaining performance makes them indispensable in ensuring operational efficiency.

The wastewater treatment industry also benefits from the capabilities of Warman rubber lined slurry pumps. They are used for transporting sludge and other particulate-laden liquids, playing a crucial role in the management and processing of waste materials.

Maintenance and Support

To maximize the lifespan and efficiency of Warman rubber lined slurry pumps, regular maintenance is vital. Fortunately, these pumps are designed for easy access to components, facilitating quick inspections and repairs. Routine maintenance tasks include checking for wear on the rubber lining, monitoring flow rates, and ensuring that the impeller remains in good condition.

Manufacturers typically offer comprehensive support, including replacement parts and technical assistance, ensuring that operators can quickly address any issues that may arise. This level of support enhances the reliability of operations, allowing businesses to minimize downtime and maintain productivity.

Conclusion

The Warman rubber lined slurry pump represents a robust solution for industries that require reliable transport of abrasive and corrosive materials. With their durable construction, excellent hydraulic performance, and ease of maintenance, these pumps have established themselves as a trusted choice for slurry handling applications. As industries continue to evolve and face new challenges, the Warman rubber lined slurry pump is well-equipped to meet the demands of modern operations, ensuring efficient and effective material transfer for years to come.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025