Dec . 11, 2024 11:18 Back to list

vertical sump pump parts factories

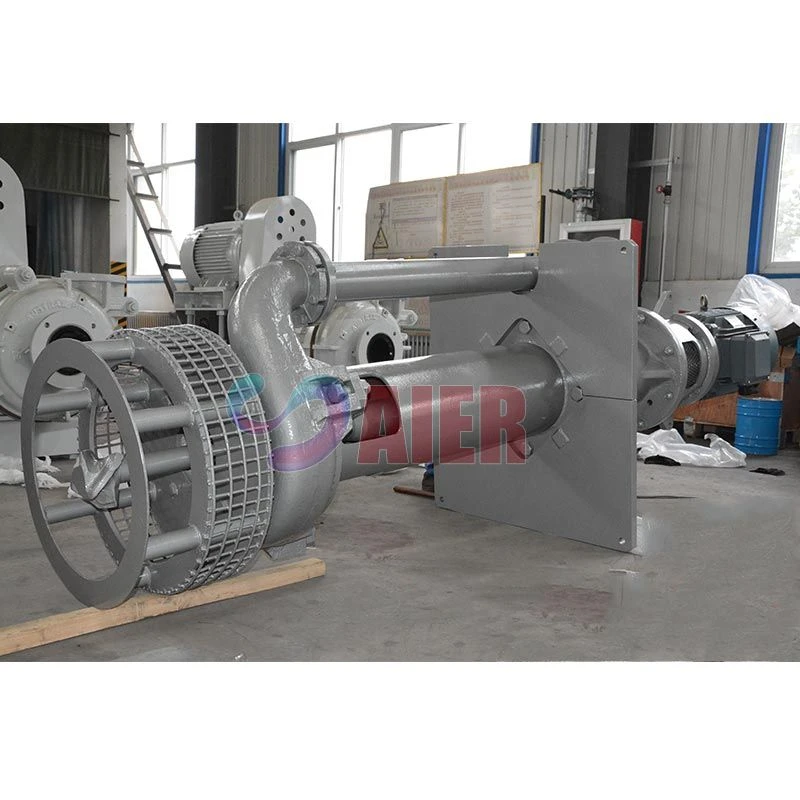

Understanding Vertical Sump Pump Parts and Their Manufacturing

Vertical sump pumps play a crucial role in various industries, particularly in managing water and wastewater. Unlike traditional pumps, vertical sump pumps are designed to operate efficiently in deep, confined spaces where space is limited. Understanding the parts that make up these pumps and their manufacturing processes is essential for ensuring optimal performance and longevity.

Key Components of Vertical Sump Pumps

Vertical sump pumps consist of several key parts, each serving an important function

1. Impeller The impeller is one of the most critical components. It is responsible for converting rotational energy from the motor into kinetic energy in the fluid, enabling efficient movement of water or other liquids. The design and material of the impeller can significantly affect the pump's performance and durability.

2. Suction Bell This component connects the pump to the sump or reservoir where the liquid is drawn from. A well-designed suction bell minimizes turbulence and maximizes flow efficiency, preventing issues such as cavitation.

3. Column Pipe The column pipe extends from the pump's casing to the discharge point. It is essential for directing the pumped liquid to the desired location. The length and diameter of the column pipe should be carefully selected based on the application requirements.

4. Motor The motor drives the impeller and is available in various configurations, including electric and hydraulic options. The choice of motor affects the pump's energy efficiency and operational capabilities.

5. Seal and Bearing Systems Seals are crucial for preventing leaks and protecting the motor from exposure to liquids. Bearings support the rotating components and ensure smooth operation. The material and design of seals and bearings impact the overall robustness of the pump.

6. Discharge Fitting This is where the pumped liquid exits the pump. The fitting needs to be compatible with the piping system to ensure a proper connection and prevent backflow.

vertical sump pump parts factories

Manufacturing Process of Vertical Sump Pump Parts

The manufacturing of vertical sump pump parts involves several stages, each aiming to ensure high quality and performance standards

1. Material Selection The first step is selecting appropriate materials, which may include stainless steel, cast iron, or specialized polymers, depending on the pump’s application and the nature of the liquid being pumped.

2. Casting and Machining For parts like the impeller and suction bell, casting is often used. Once cast, parts are machined to precise specifications to ensure a proper fit and function. This step is crucial as even minor deviations can affect pump efficiency.

3. Assembly After individual parts are manufactured, they are assembled in a clean environment to prevent contamination. Each component is carefully fitted together, and the motor is installed to complete the assembly process.

4. Testing Before a pump reaches the market, it undergoes rigorous testing to evaluate performance under various conditions. Tests include checking for leaks, flow rate, and energy efficiency. This ensures that every pump meets the manufacturer's standards and complies with industry regulations.

5. Quality Assurance Throughout the manufacturing process, quality assurance measures are taken to detect any defects early. This can include inspections at various stages and utilizing advanced technologies for measuring and testing.

Conclusion

Understanding the parts and manufacturing processes of vertical sump pumps is essential for anyone involved in the industry. From the design of the impeller to the assembly and testing of the final product, each step contributes to ensuring that the pump operates effectively and efficiently. As industries continue to evolve, the demand for high-quality vertical sump pumps will remain crucial, making it imperative for manufacturers to adhere to strict quality standards and innovative practices.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025