Nov . 09, 2024 21:57 Back to list

Vertical Sump Mining Slurry Pump Solutions for Efficient Resource Extraction and Handling

Vertical Sump Mining Slurry Pump Supplies An Overview

As the mining industry continues to evolve and expand, the demand for efficient and reliable pumping solutions has never been greater. One of the integral components in this sector is the vertical sump mining slurry pump, which is designed specifically to handle the rigorous conditions of mining operations. In this article, we’ll explore the importance of these pumps, their applications, the technical specifications that make them suitable for mining, and the supplies required for their optimal performance.

Understanding Vertical Sump Pumps

Vertical sump pumps are specialized hydraulic devices designed to pump slurry—a mixture of liquid and solid particles—out of sumps and pits. Unlike standard pumps, which may be horizontal in orientation, vertical sump pumps have a vertical orientation that allows them to operate in confined spaces with a minimal footprint. This configuration is particularly beneficial in mining environments, where space may be limited and conditions can be harsh.

Slurry is an intrinsic byproduct of various mining processes, often resulting from the excavation of minerals. The presence of abrasive materials in the slurry can lead to rapid wear and tear on pumping equipment. Therefore, the choice of a pump that can withstand these conditions is critical to maintaining operational efficiency.

Applications in Mining

Vertical sump mining slurry pumps are widely used across various mining applications, including

1. Dewatering One of the primary uses of these pumps is the dewatering of mines. They help to remove excess water that accumulates due to rainfall, groundwater infiltration, or operational processes.

2. Slurry Transport In mines, slurry needs to be transported from one location to another, whether it’s from a processing plant to a tailings storage facility or between different stages of the mining process. Vertical sump pumps facilitate this transport efficiently.

3. Tailings Management After the extraction of valuable minerals, the remaining material, or tailings, must be managed effectively. Vertical sump pumps play a crucial role in transferring tailings to designated storage areas.

4. Mineral Processing In addition to dewatering and slurry transport, these pumps are used in various stages of mineral processing, including the recovery of valuable elements and the separation of liquid and solid materials.

Technical Specifications

When selecting a vertical sump mining slurry pump, several technical specifications must be considered to ensure that it can perform adequately under challenging conditions

vertical sump mining slurry pump supplies

- Material Construction Pumps must be constructed from durable materials that are resistant to abrasion and corrosion, such as high-chrome alloys or rubber-lined materials.

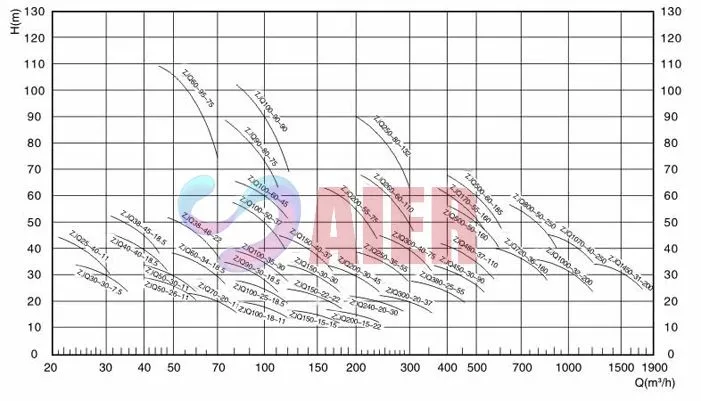

- Flow Rate and Head The required flow rate and total dynamic head (TDH) are critical factors that determine the pump’s efficiency. Pumps should be selected based on the specific requirements of the mining operation.

- Suction Design The design of the suction inlet is essential for minimizing the risk of blockages and ensuring efficient operation in slurry conditions.

- Seal and Bearing Configurations Effective sealing systems and robust bearing designs are crucial in preventing leaks and ensuring the longevity of the pump.

Supplies and Maintenance

To guarantee the optimal performance of vertical sump mining slurry pumps, specific supplies and maintenance routines are necessary.

1. Replacement Parts Regular wear parts such as impellers, liners, and seals need to be stocked to minimize downtime.

2. Lubrication Proper lubrication of bearings and seals is essential to ensure smooth operation and extend the lifespan of the integral components.

3. Routine Inspections Implementing a regular inspection schedule allows for the early detection of wear and potential issues, preventing costly breakdowns.

4. Training and Support Operators should be trained on the correct usage and maintenance procedures for these pumps to ensure they operate at peak efficiency.

Conclusion

In summary, vertical sump mining slurry pumps are vital components in the mining industry, designed to handle the unique challenges posed by slurry conditions. Understanding their applications, technical specifications, and maintenance requirements is essential for any mining operation seeking to optimize performance and reduce downtime. By investing in high-quality pumps and proper maintenance strategies, mining companies can enhance their productivity, ensuring that they are well-equipped to meet the demands of this dynamic industry.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025