Oct . 16, 2024 13:57 Back to list

Leading Supplier of Vertical Submersible Slurry Pumps for Industrial Applications

Vertical Submersible Slurry Pump Supplier An Overview

The demand for efficient and reliable slurry handling solutions has led to the rise of vertical submersible slurry pumps in various industries. These pumps, designed to operate underwater, are ideal for transporting abrasive and sediment-laden fluids in mining, construction, and wastewater management. For businesses seeking these specialized pumps, finding the right supplier is crucial for ensuring optimal performance and durability.

What is a Vertical Submersible Slurry Pump?

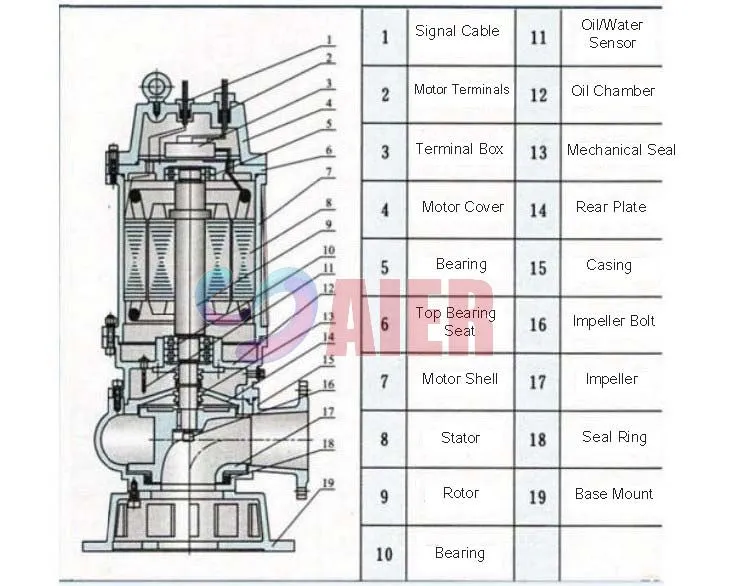

A vertical submersible slurry pump is a type of pump that is submerged in the fluid being pumped. It features a vertical design, which allows it to directly move slurry from the pit or tank without the need for additional suction piping. These pumps are engineered with robust materials to withstand the abrasive nature of slurry, consisting of solid particles suspended in liquids. The motor is typically located above the fluid level, protecting it from exposure to the harsh environment.

Benefits of Vertical Submersible Slurry Pumps

1. Efficient Slurry Transportation The vertical orientation reduces the risk of clogging, as solids can be effectively moved through the pump without obstruction. This makes them highly efficient for applications in mining where thick, viscous slurries are common.

2. Space-Saving Design Since the pump is submerged, it requires less surface area compared to horizontal pumps. This compact design is particularly advantageous in environments with limited space.

3. Reduced Maintenance Requirements With a submersible pump, there is less wear and tear on components that are susceptible to external factors, leading to lower maintenance costs and downtime.

4. Versatility These pumps can be utilized in a variety of applications, from mineral processing to industrial sludge handling. This flexibility makes them a valuable asset across multiple sectors.

Choosing the Right Supplier

vertical submersible slurry pump supplier

When searching for a vertical submersible slurry pump supplier, several factors should be considered to ensure that you find a reliable and high-quality product.

1. Experience and Reputation Look for suppliers with a proven track record in the industry. Companies with extensive experience are more likely to provide durable and efficient pumps tailored to your needs. Checking customer reviews and testimonials can also provide insights into their reputation.

2. Product Range A reputable supplier will offer a variety of models and specifications. This allows clients to select a pump that fits their specific requirements, be it head height, flow rate, or material handling capability.

3. Quality Assurance Verify that the supplier adheres to industry standards in manufacturing pumps. Quality assurance processes, certifications, and guarantees can give you peace of mind regarding the reliability and longevity of the pump.

4. Technical Support and Service A good supplier should offer comprehensive after-sales support, including installation services, maintenance advice, and troubleshooting. Access to technical assistance can be invaluable in ensuring that your pump operates efficiently over time.

5. Cost-Effectiveness While price should not be the only deciding factor, it is essential to find a supplier that offers competitive pricing without compromising on quality. Look for options that provide value for money, taking into account both upfront costs and long-term operational efficiency.

6. Customization Options Depending on your specific application, you may require tailored solutions. Suppliers that offer customization according to your operational needs can provide a significant advantage.

Conclusion

Vertical submersible slurry pumps are a vital component in many industrial processes, ranging from mining to wastewater management. Selecting the right supplier is essential to ensure that you receive a pump that meets your operational demands effectively. By considering factors such as experience, product range, quality assurance, service, and customization, you can find a reliable partner to support your slurry handling needs. Investing time in the selection process will lead to improved performance, reduced downtime, and enhanced productivity in the long run.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025