Dec . 10, 2024 20:29 Back to list

Leading Manufacturer of Vertical Centrifugal Slurry Pumps for Various Applications and Industries

Understanding Vertical Centrifugal Slurry Pumps and Their Manufacturers

Vertical centrifugal slurry pumps play a pivotal role in various industries, particularly in the mining, construction, and chemical sectors. They are specially designed to handle abrasive and viscous slurries that can cause significant wear and tear on conventional pumping systems. As industries continue to evolve and demand higher efficiency and reliability, understanding the nuances of vertical centrifugal slurry pump manufacturers becomes essential for selecting the right equipment for specific applications.

What is a Vertical Centrifugal Slurry Pump?

Vertical centrifugal slurry pumps are characterized by their vertical orientation and their ability to move highly viscous and abrasive materials. Designed to efficiently transport slurries—mixtures of liquid and solid particulates—these pumps use centrifugal force generated by a rotating impeller to propel the slurry through the pump and into the discharge line.

The construction of vertical centrifugal slurry pumps typically involves high-grade materials such as stainless steel, cast iron, or rubber-lined components, which provide resistance to wear and corrosion. This durability is crucial, given the harsh conditions under which these pumps operate. The design often incorporates a vertical shaft that minimizes the footprint, making them suitable for confined spaces.

Applications of Vertical Centrifugal Slurry Pumps

A wide range of industries employs vertical centrifugal slurry pumps for various applications, including

1. Mining and Minerals Processing In mining operations, these pumps are used to transport slurries of crushed ore, waste material, and water. Their ability to handle high solid concentrations makes them invaluable for dewatering and tailings management.

2. Construction The construction industry uses these pumps to manage slurries created during excavation and foundation work. They are essential in transporting concrete and other heavy mixtures.

3. Chemical Processing In the chemical sector, vertical centrifugal slurry pumps are used for transferring corrosive slurries and other harsh materials. Their robust design ensures safety and reliability in operations.

4. Wastewater Management These pumps play a critical role in wastewater treatment facilities, where they transport sludge and other solid-laden liquids efficiently.

vertical centrifugal slurry pump manufacturer

Choosing the Right Manufacturer

When selecting a vertical centrifugal slurry pump, it is vital to consider the manufacturer’s reputation, expertise, and product offerings. Leading manufacturers not only provide high-quality pumps but also offer comprehensive services, including technical support, installation, and maintenance.

Key Factors to Consider

1. Experience and Expertise Reputable manufacturers typically have years of experience in the industry. Their expertise often translates into innovative designs that enhance performance and longevity.

2. Material Selection The best manufacturers use top-tier materials in the construction of their pumps. Be sure to inquire about the types of materials used, especially if the pump will handle corrosive or abrasive substances.

3. Customization Options Different applications may require specific configurations. A good manufacturer should provide customization options to meet unique operational needs.

4. Support Services Choose a manufacturer that offers excellent after-sales support, including installation guidance, maintenance services, and quick replacement parts availability.

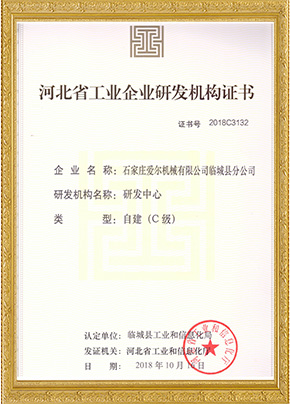

5. Certifications and Standards Ensure that the manufacturer adheres to local and international standards and certifications. This compliance often reflects their commitment to quality and safety.

Conclusion

Vertical centrifugal slurry pumps are integral to the efficiency and success of various industrial processes. Understanding their functionality and the significance of choosing a reputable manufacturer can significantly impact operational performance and cost-effectiveness. By considering factors such as experience, material quality, customization, and support services, businesses can make informed decisions that enhance their operational capabilities. As industries continue to face evolving challenges, the role of reliable equipment like vertical centrifugal slurry pumps will remain critical in ensuring productivity and efficiency.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025